Intelligent monitoring method for potential fracture area of reinforced soil retaining wall

A technology of intelligent monitoring and reinforced soil, which is used in basic structure testing, hydraulic engineering, image data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

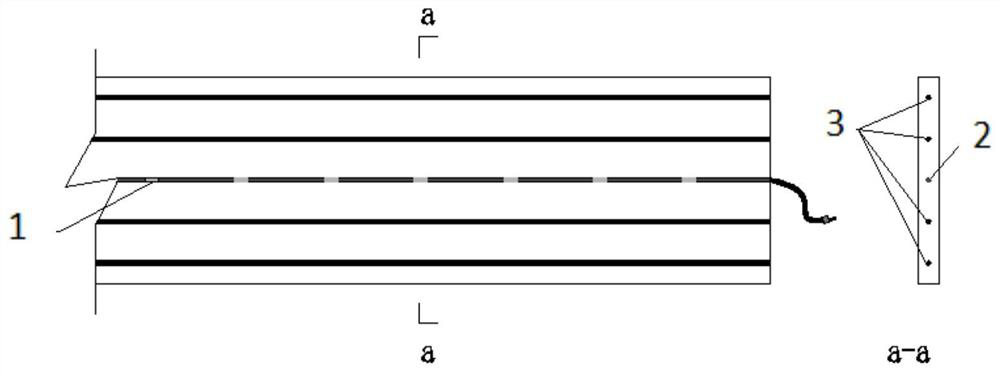

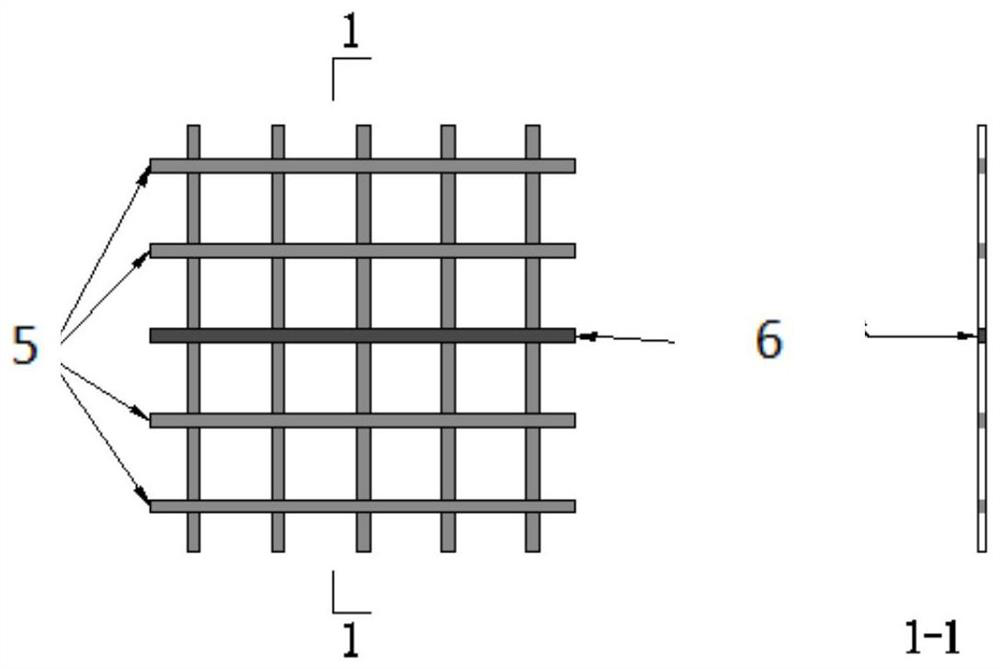

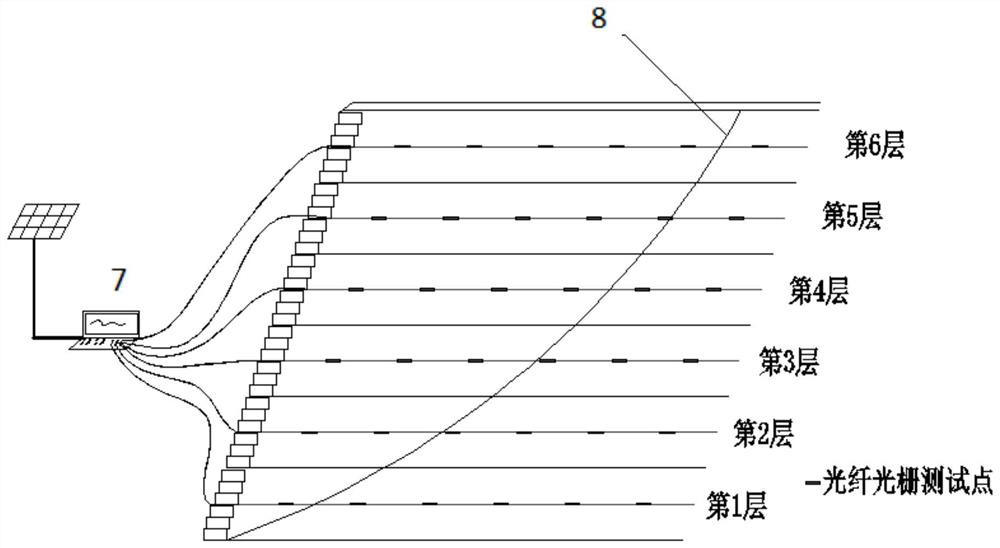

[0030] Optical fiber measurement technology has developed rapidly and is relatively mature. It has the advantages of small size, convenient installation, good durability, stable transmission signal, high sensitivity, and real-time monitoring. It has been widely used in many fields. Fiber Bragg grating sensor sensor not only has the characteristics of fiber optic sensor, but also can realize real-time monitoring of internal multi-point strain. It is the testing technology with the most development potential and application value in fiber optic sensing technology. The principle of fiber grating sensor monitoring is that the optical parameters of the optical fiber will also change when the structure under test is deformed. Call out its deformation index to reflect the deformation state of the measured structure. Through industrial professional processing technology, the ordinary ribbed belt and the fiber grating sensor are coupled together to form an intelligent ribbed belt (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com