Monitoring method for grain stock in barn

A storage capacity and granary technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of tediousness, poor measurement accuracy, and complicated measurement process, and achieve the effects of high measurement accuracy, reduced labor costs, and simple monitoring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

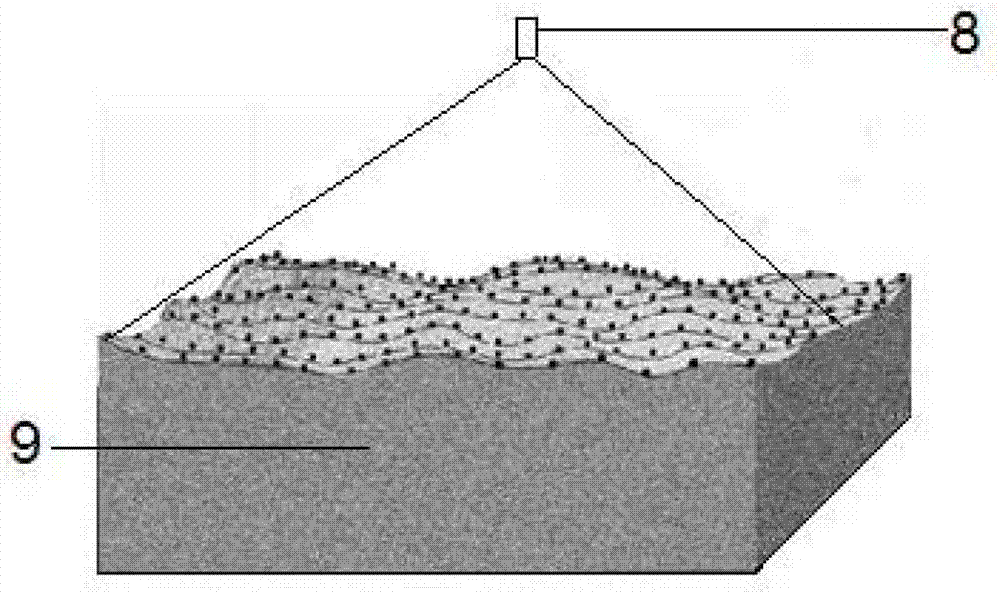

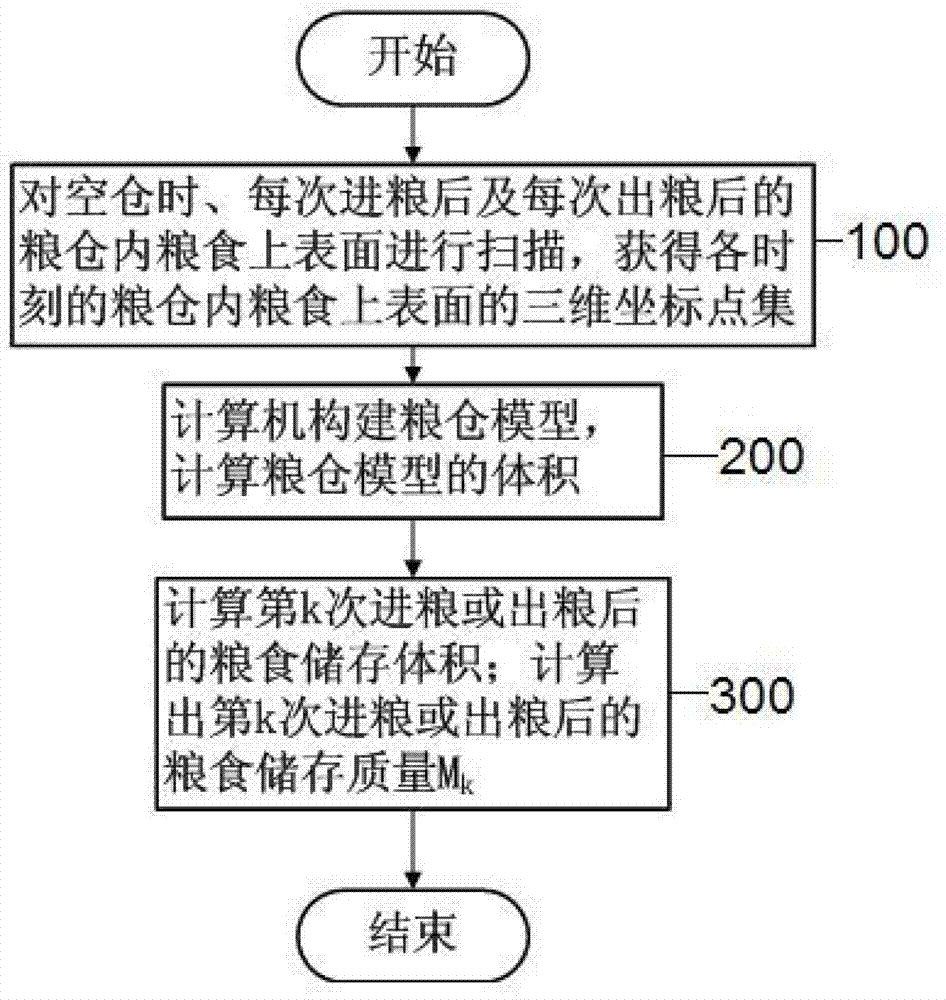

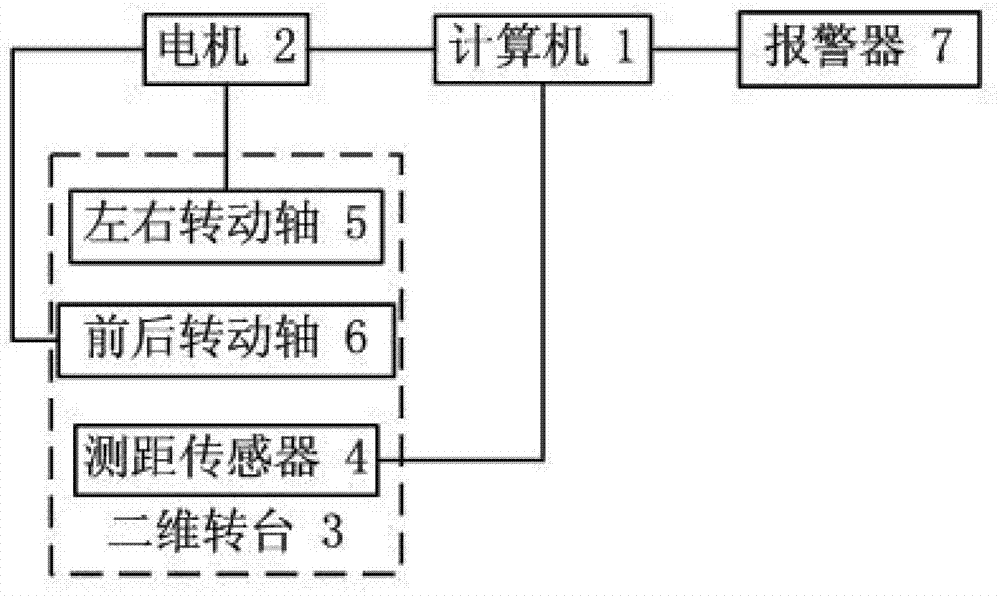

[0035] like figure 1 The illustrated embodiment is a method for monitoring grain storage in a granary. The monitoring method is suitable for a grain storage monitoring device. The monitoring device 8 is located on the top of the granary, and the monitoring device is connected to the computer 1; The device comprises a motor 2 located on the top of the granary, an alarm 7 and a two-dimensional turntable 3 connected with the motor; the rotating shaft of the motor is connected with the two-dimensional turntable; the bottom of the two-dimensional turntable is provided with a distance sensor 4; The two-dimensional turntable includes a left and right rotation axis 5 and a front and rear rotation axis 6; the rotation angle of the left and right rotation axes is -58° to 58°. The lower part of the two-dimensional turntable is provided with a dust cover for covering the ranging sensor.

[0036] The rotation angle of the left and right rotation axis is -58° to 58°. The rotation angle of...

Embodiment 2

[0050] Embodiment 2 includes all structures and steps in Embodiment 1, and also includes the following steps:

[0051] Every 8 hours, carry out a monitoring scan on the upper surface of the grain in the granary, repeat the steps 100 to 300 to calculate the grain quality variation between adjacent monitoring scanning times, if there is no artificial grain change between adjacent monitoring scanning times operation and the grain quality change rate exceeds 0.5%, the alarm will alarm.

[0052] For example: a monitoring scan was carried out at 2:00 on January 3, and the grain storage quality was 120,000 kg; a monitoring scan was carried out at 10:00 on January 3, and the grain storage quality was 119,200 kg; The rate of change is 0.67%; and there is no manual food intake and output operation between 2:00 on January 3 and 10:00 on January 3, the controller will control the alarm to alarm. It shows that there are abnormal situations such as grain rot, rat infestation or insects in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com