A gasoline that boosts engine power

An engine and power technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of limited addition, difficulty, easy deposition and cleaning, etc., to achieve anti-wear lubrication, prevent carbon deposition, and high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

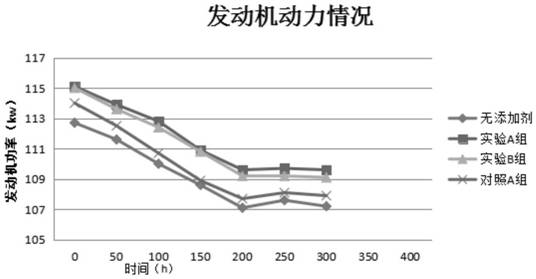

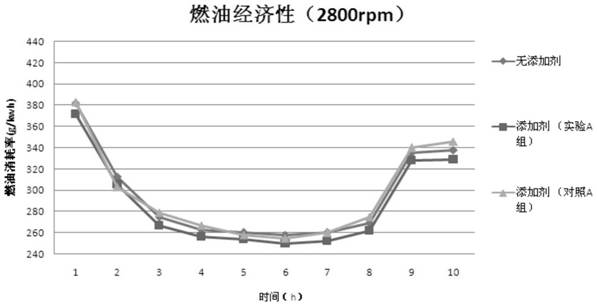

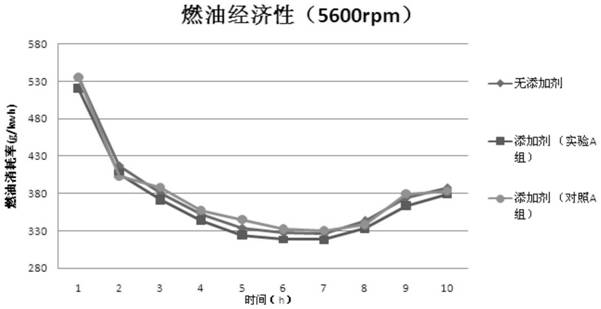

[0027] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings.

[0028] 1. Oil preparation

[0029] All the raw materials used in the present invention can be purchased from the market, or can be prepared by themselves using known conventional preparation techniques. According to the weight ratio, each component is blended and compounded at 15-30°C. First, the 98# base gasoline purchased from Sinopec is heated at a constant temperature, and then the dispersant, viscosity modifier and surfactant are added, and the mixture is fully stirred for 20- After 30 minutes to achieve uniformity and the viscosity is basically stable, then add compound friction modifier, antioxidant, detergent and other admixtures, and stir again for 20-30 minutes to obtain a uniformly mixed oil product. The composition of the prepared oils is listed in Table 1.

[0030] Table 1

[0031]

[0032]

[0033] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com