Silicate-modified polyetheramine polyurethane antifouling coating and application thereof

A technology of polyetheramine polyurethane and anti-fouling coatings, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of increased power and fuel consumption, increased fuel consumption, and short service life , to achieve the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

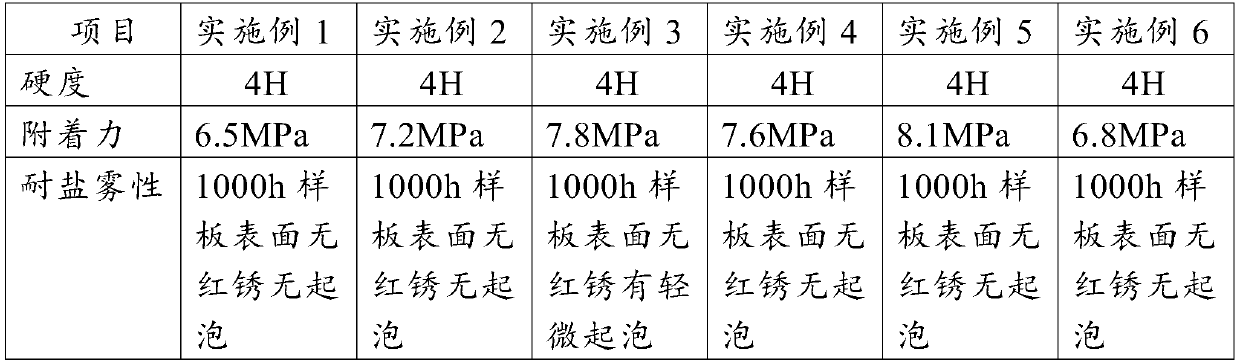

Embodiment 1

[0024] A: Take 5.0 parts of water-soluble polyetheramine, 10 parts of potassium silicate, 10 parts of water, 60 parts of pigments: silicon oxide, red iron oxide, talcum powder, barium sulfate, sericite 1 part, 4 parts, 20 parts, 20 parts, 15 parts, after mixing, high-speed dispersion at 2000rpm for 150min, and sand grinding to a fineness of 5μm.

[0025] B: 13 parts of Wanhua water-based curing agent 268, mixed with 1 part of calcined magnesium oxide, 2 parts of zinc oxide, and 10 parts of aluminum oxide, then dispersed at 2000 rpm for 150 minutes at high speed, and sand-milled to a fineness of 6 μm.

[0026] A: B = 3:1 (weight ratio) and mix well.

Embodiment 2

[0028] A: Take 6.0 parts of water-soluble polyetheramine, 11 parts of alkaline silica sol, 5 parts of water, 60 parts of pigments: 2 parts, 4 parts, 10 parts, 30 parts of each of silicon oxide, iron oxide red, talcum powder, and sericite, After mixing, disperse at a high speed of 2600 rpm for 120 minutes, and grind to a fineness of 13 μm.

[0029] B: 16 parts of Wanhua water-based curing agent 270, mixed with 2 parts of calcined magnesium oxide, 3 parts of zinc oxide, and 12 parts of aluminum oxide, then dispersed at 2600 rpm for 120 minutes at high speed, and sand-milled to a fineness of 16 μm.

[0030] A: B=3.2:1 (weight ratio) and mix well.

Embodiment 3

[0032] A: Take 7.0 water-soluble polyetheramine, 12 parts of sodium silicate, 15 parts of water, 63 parts of pigments: silicon oxide, red iron oxide, talcum powder, barium sulfate, sericite, 3 parts, 5 parts, 20 parts, 20 parts Parts, 15 parts, after mixing, high-speed dispersion at 3000rpm for 100min, and sand milling to a fineness of 9μm.

[0033] B: 15 parts of Wanhua water-based curing agent 278, mixed with 1 part of calcined magnesium oxide and 10 parts of aluminum oxide, dispersed at 3000 rpm for 100 minutes at high speed, and sand-milled to a fineness of 11 μm.

[0034] A: B=3.3:1 (weight ratio) and mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com