Functional micro-spiral and preparation method therefor

A micro-spiral and functional technology, applied in the field of polymer functional material preparation, can solve problems such as unsuitability for mass production, material limitations, and poor controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

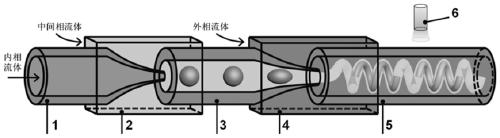

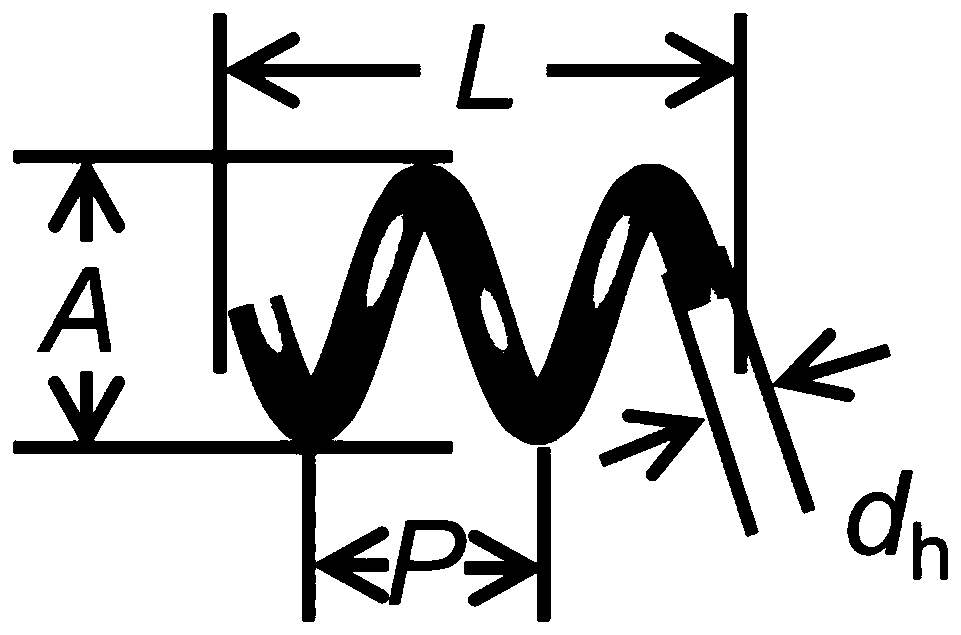

Method used

Image

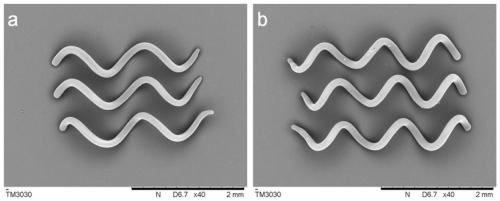

Examples

Embodiment 1

[0068] In this embodiment, a method for preparing a functional microhelix is provided, and the steps are as follows:

[0069] (1) Preparation of internal phase, intermediate phase, external phase and stable phase fluid

[0070] Prepare internal phase fluid: Dissolve photoinitiator 1173 and surfactant polyglyceryl ricinoleate (PGPR) in ethoxylated trimethylolpropane triacrylate (ETPTA) at room temperature to obtain internal phase fluid; In the internal phase fluid, the mass fraction of photoinitiator 1173 is 10%, and the mass fraction of PGPR is 1%.

[0071] Prepare interphase fluid: Sodium alginate and surfactant Pluronic F-127 (F-127) are dissolved in pure water at room temperature to obtain interphase fluid; in the interphase fluid, the mass fraction of sodium alginate is 1.5%, The mass fraction of F-127 is 1%.

[0072] Prepare the external phase fluid: dissolve calcium chloride and F-127 in pure water at room temperature to obtain the external phase fluid; in the extern...

Embodiment 2

[0083] In this embodiment, a method for preparing a functional microhelix is provided, and the steps are as follows:

[0084] (1) Preparation of internal phase, intermediate phase, external phase and stable phase fluid

[0085] Preparation of internal phase fluid: at room temperature, photoinitiator 2959 and surfactant Tween85 are dissolved in polyethylene glycol diacrylate (PEGDA) to obtain internal phase fluid; in internal phase fluid, the mass fraction of photoinitiator 2959 is 1 %, the mass fraction of Tween85 is 10%.

[0086] Prepare interphase fluid: Sodium alginate and surfactant sodium dodecyl sulfate (SDS) are dissolved in pure water at room temperature to obtain interphase fluid; in the interphase fluid, the mass fraction of sodium alginate is 1%, The mass fraction of SDS is 1%.

[0087] Prepare the external phase fluid: at room temperature, calcium chloride and surfactant sodium dodecylsulfonate are dissolved in pure water to obtain the external phase fluid; in ...

Embodiment 3

[0097] In this embodiment, a method for preparing a functional microhelix is provided, and the steps are as follows:

[0098] (1) Preparation of internal phase, intermediate phase, external phase and stable phase fluid

[0099] Preparation of internal phase fluid: at room temperature, photoinitiator 1173 and surfactant Span80 are dissolved in ethylene glycol dimethacrylate (EGDMA) to obtain internal phase fluid; in internal phase fluid, the mass fraction of photoinitiator 1173 is 20%, the mass fraction of Span80 is 20%.

[0100] Prepare interphase fluid: Dissolve sodium alginate and sodium dodecylsulfonate in pure water at room temperature to obtain interphase fluid; in the interphase fluid, the mass fraction of sodium alginate is 3%, dodecylsulfonate The mass fraction of sodium bicarbonate is 20%.

[0101] Prepare the external phase fluid: dissolve calcium chloride and SDS in pure water at room temperature to obtain the external phase fluid; in the external phase fluid, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com