Flanging type water tank for train

A flanging and train technology, applied in locomotives and other directions, can solve the problems of short service life of the water tank, general structural firmness, and easy corrosion of solder joints, and achieve the effect of prolonging the service life, forming stable, and reducing solder joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

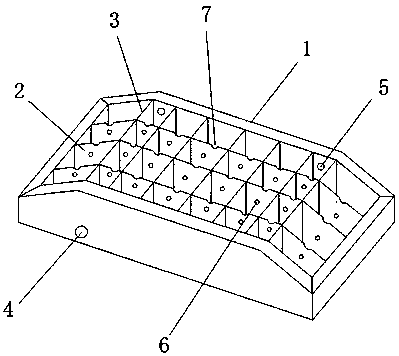

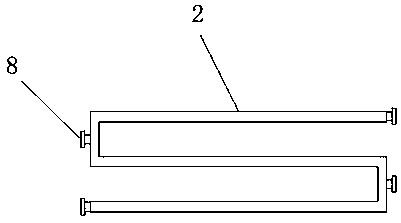

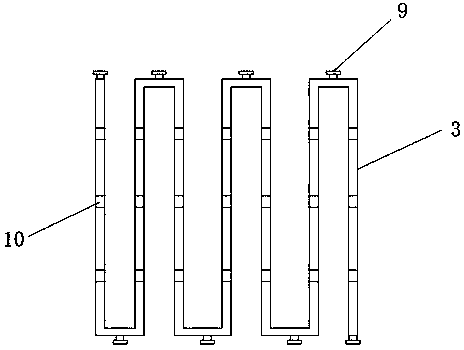

[0022] see Figure 1-4 , the present invention provides a technical solution: a flanged water tank for trains, including a tank body 1, a transverse anti-corrugation plate 2, a longitudinal anti-corrugation plate 3, a water inlet 4, a water outlet 5, and a first pressure relief hole 6 And the second pressure relief hole 7, the box body 1 is welded by cutting and bending the plate material, so that it is integrally formed, so that only the four-corner lap joints need to be welded, so that the welding points of the box body 1 are reduced, thereby ensuring the box The overall firmness of the body 1, the inner cavity of the box body 1 is horizontally installed with a horizontal anti-corrugation plate 2, and the inner cavity of the box body 1 is longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com