Wind wheel and air blower applying wind wheel

A wind wheel and joint technology, which is applied in the blower field, can solve the problems of weak welding between the wind blade and the bottom panel, easy occurrence of missing welding, and large jump of the wind wheel, so as to improve welding efficiency, reduce welding points, and reduce welding points Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

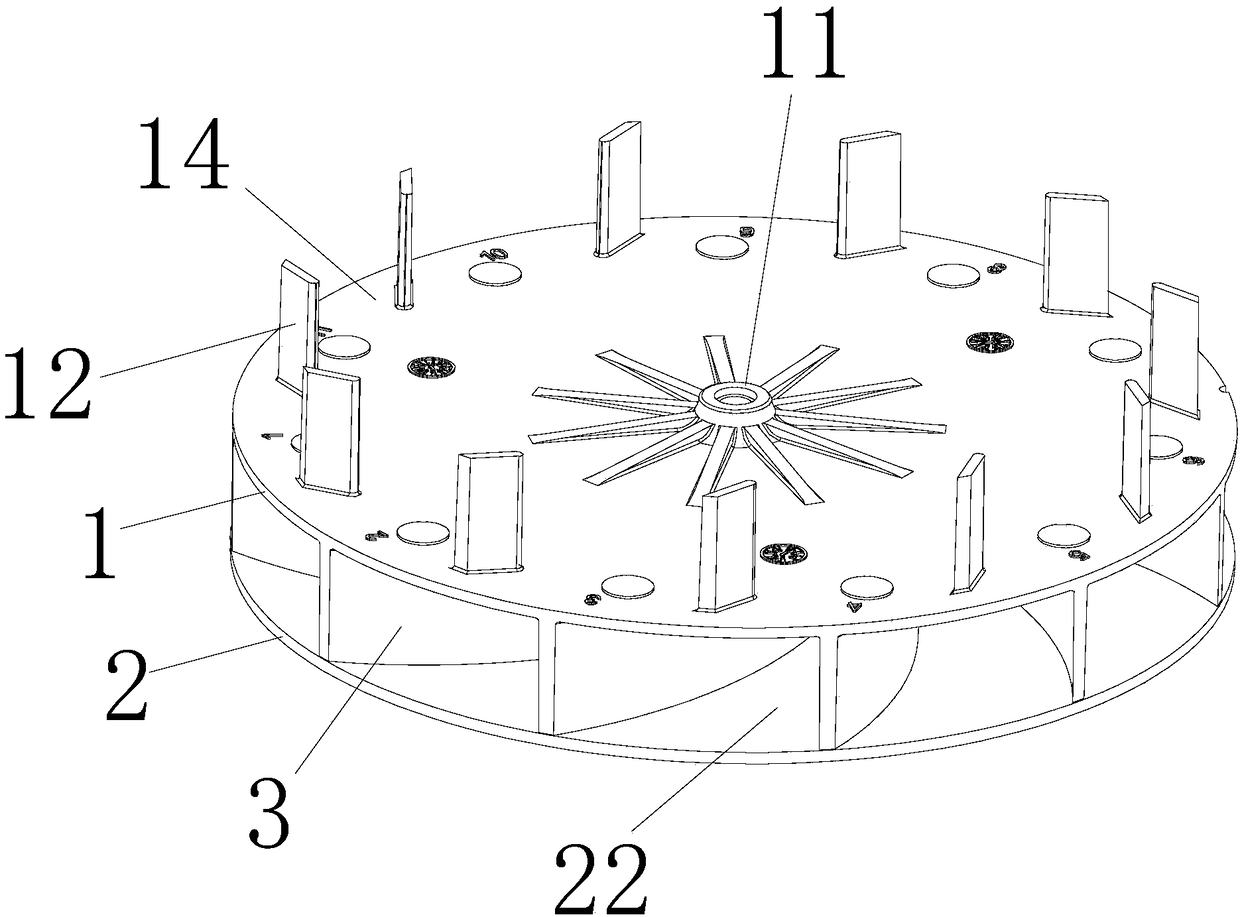

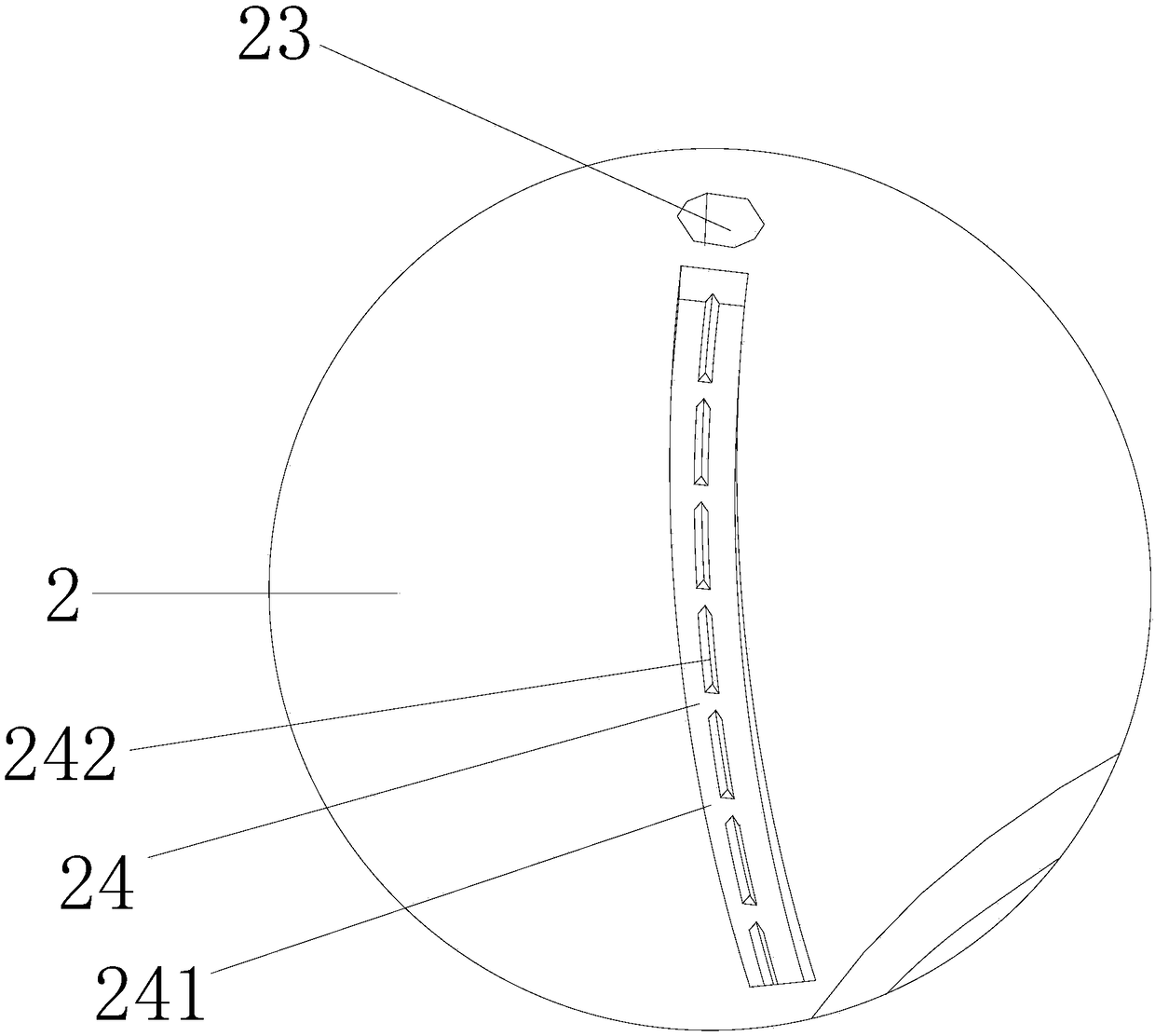

[0031] Such as Figure 1 to Figure 8 As shown, the present embodiment is a wind wheel, comprising a top panel 1 and a bottom panel 2 with several wind blades 3, several wind blades 3 protrude from the lower end surface 13 of the top panel 1, and several wind blades 3 are connected with The top panel 1 is integrally injection-molded, and several wind blades 3 are located between the top panel 1 and the bottom panel 2, and an air inlet 21 is arranged in the middle of the bottom panel 2, and an air duct 22 is formed between two adjacent wind blades 3, and the center of the top panel 1 A connection seat 11 connected to the motor shaft is provided, and several positioning columns 32 protrude from the end surface 31 connected to the bottom panel 2 of the wind blade 3, and the bottom panel 2 is provided with the positioning columns 32 passing through the mounting holes 23 and welded The wind blade 3 and the bottom panel 2 are fixed together, and the end surface 31 of the wind blade 3...

Embodiment 2

[0039] Such as Figure 9 and Figure 10 As shown, a blower includes a volute 4, a cover plate 5, a motor 6, a motor shaft 7 and a wind wheel 9, the volute 4 and the cover plate 5 are installed and connected together to form a cavity 8, and the wind wheel 9 is installed in the cavity 8 Inside, the volute 4 is provided with an air outlet 41, and the cover plate 5 is provided with an air inlet 51, and the feature is that the wind wheel 9 is any one of the wind wheels 9 described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com