Novel air suspension guide arm and automobile comprising same

A technology of air suspension and guide arm, applied in the direction of suspension, elastic suspension, vehicle spring, etc., which can solve the problems of early wear and tear of guide arm bushing, unreasonable design structure, long guide arm cantilever, etc., and achieve uniform force , simple structure and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

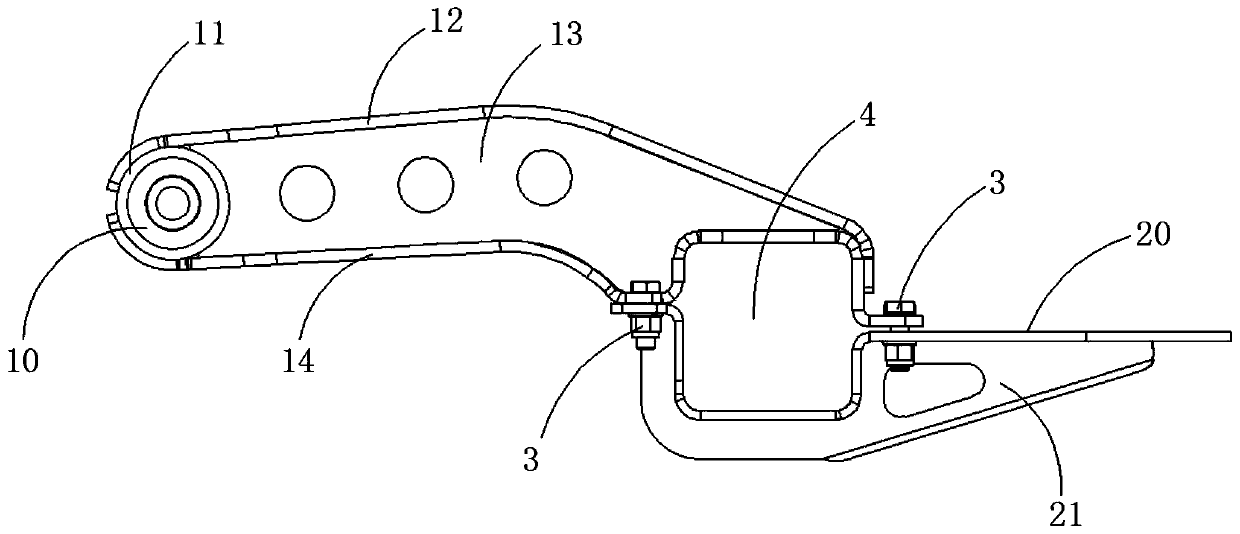

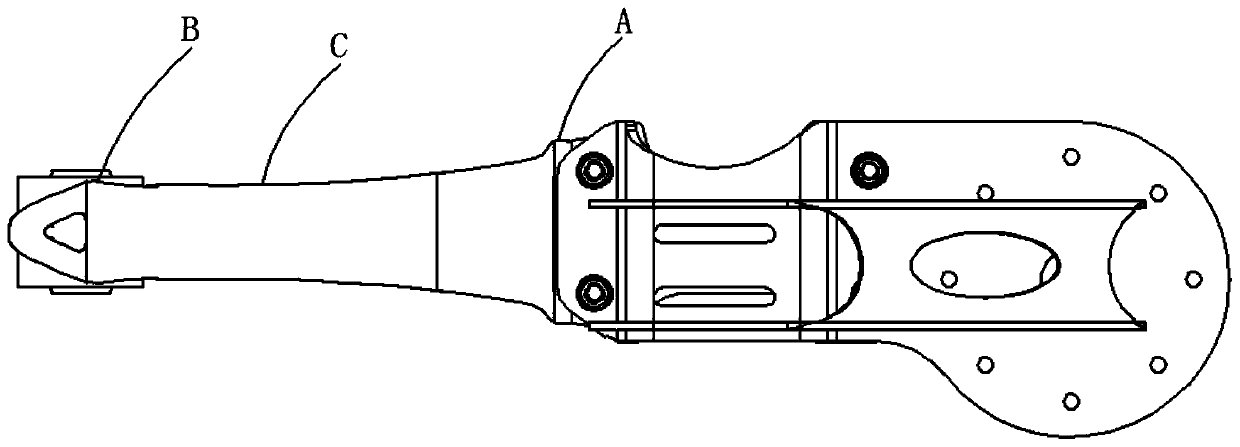

[0032] see figure 1 with figure 2 As shown, a new type of air suspension guide arm provided by this embodiment is applied in an automobile air suspension system of a square axle axle, and includes a control arm 1. The control arm 1 includes an upper side plate 12, a lower side plate 14, a vertical Plate 13 and torsion bushing 11, torsion bushing 11 is respectively connected with one or more in upper side plate 12, lower side plate 14 or vertical plate 13, and the end of control arm 1 away from torsion bushing 11 is connected with first The axle fixing plate 16 is used to connect the axle 6, the vertical plate 13 is located between the upper side plate 12 and the lower side plate 14, and the vertical plate 13 is connected with the upper side plate 12 and the lower side plate 14 respectively. The control arm 1 also includes a shaft sleeve 10, which is located inside the torque sleeve 11, and the torque sleeve 11 is connected with the bracket bolts through the shaft sleeve 10, ...

Embodiment 2

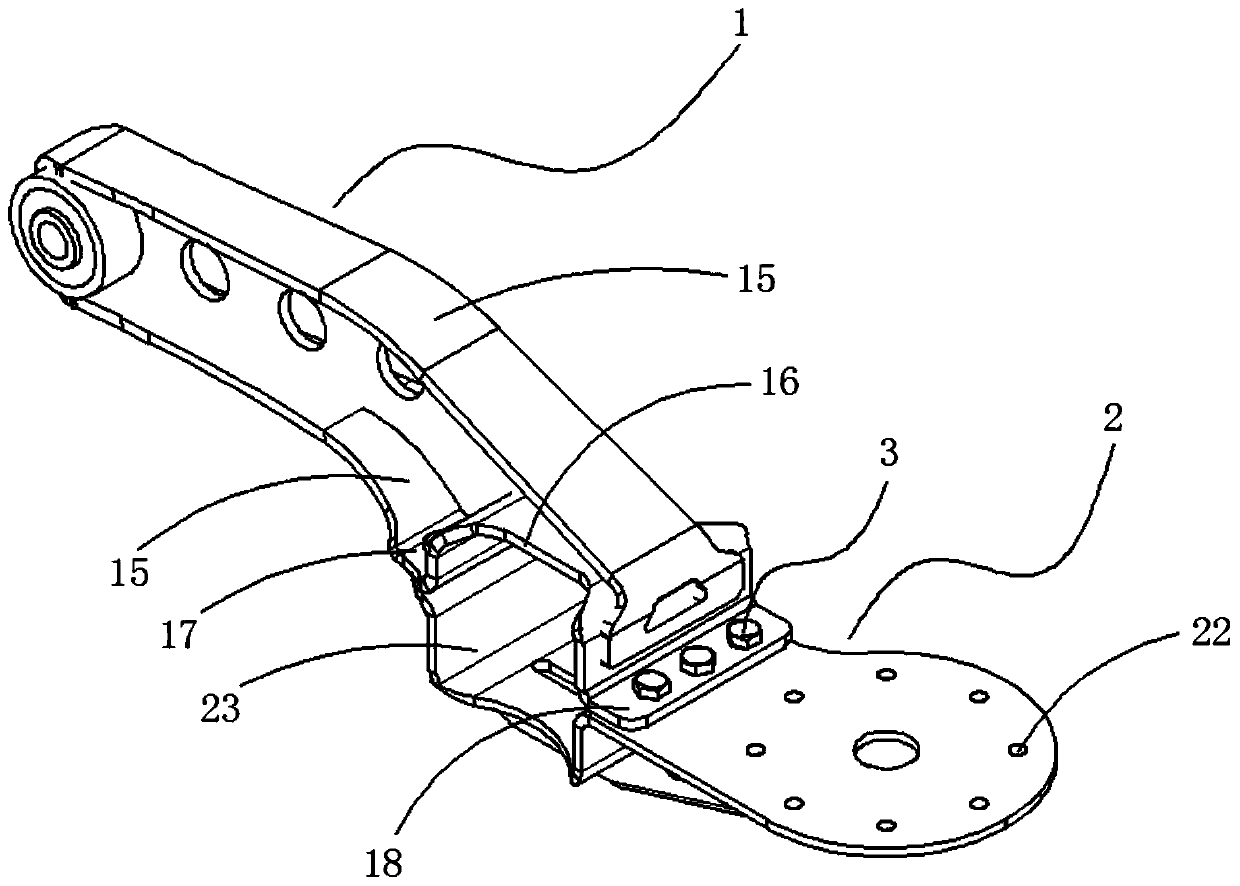

[0038] see Image 6 with Figure 7 As shown, a new type of air suspension guide arm provided in this embodiment is applied in the automobile air suspension system of the circular axle axle. Specifically, the mounting base 2 is connected with the control arm 1 to form the circular axle axle mounting hole 5 , for connection with the round axle axle. Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com