chip transfer method

A chip transfer and chip technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high production cost and low transfer efficiency, and achieve the effect of improving transfer efficiency, realizing density adjustment, and reducing transfer cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

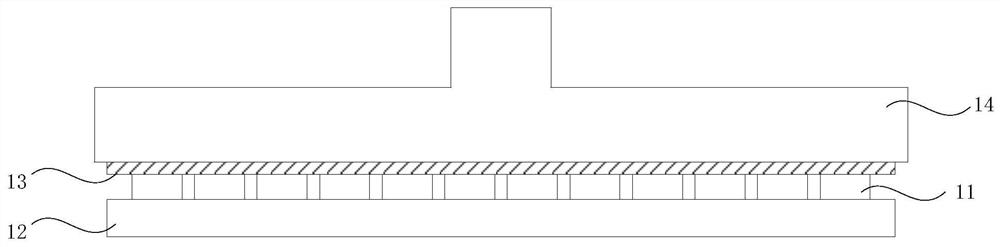

[0047] figure 1 A flow chart of a chip transfer method provided by Embodiment 1 of the present invention specifically includes the following steps:

[0048] Step 110, covering the first side of the at least two chips to be transferred with the first surface of the elastic film to absorb the at least two chips to be transferred with a first distance, the first surface of the elastic film is coated with Adhesive layer;

[0049] In this embodiment, the adhesive layer coated on the first surface of the elastic film is used to absorb at least two chips to be transferred. The first spacing is the spacing between two adjacent chips, which may be the original spacing after the wafer is cut, or the spacing between two adjacent chips after at least two chips to be transferred have been rearranged.

[0050] After covering the first surface of the elastic film on the first sides of at least two chips to be transferred, it also includes: pressing the second surface of the elastic film by...

Embodiment 2

[0092] Figure 9 A flow chart of a chip transfer method provided by Embodiment 1 of the present invention specifically includes the following steps:

[0093] Step 210, covering the first surface of the elastic film on the first side of at least two chips to be transferred according to the first position mark, so as to absorb the at least two chips to be transferred with a first distance, the elastic film The first surface of the elastic film is coated with an adhesive layer, and the elastic film is provided with a first position mark;

[0094] In this embodiment, the adhesive layer coated on the first surface of the elastic film is used to absorb at least two chips to be transferred. The first spacing is the spacing between two adjacent chips, which may be the original spacing after the wafer is cut, or the spacing between two adjacent chips after at least two chips to be transferred have been rearranged. The first position mark is arranged on the elastic film, and may be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com