Multi-nozzle alcohol-based burner

A burner and multi-nozzle technology, applied in the direction of burner, liquid fuel burner, combustion method, etc., can solve the problem of flue gas nitrogen oxide emission not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

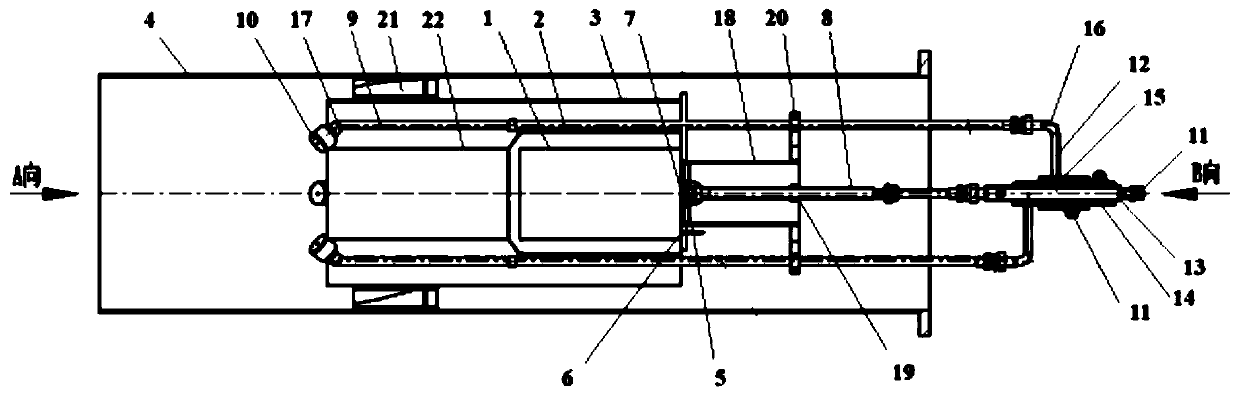

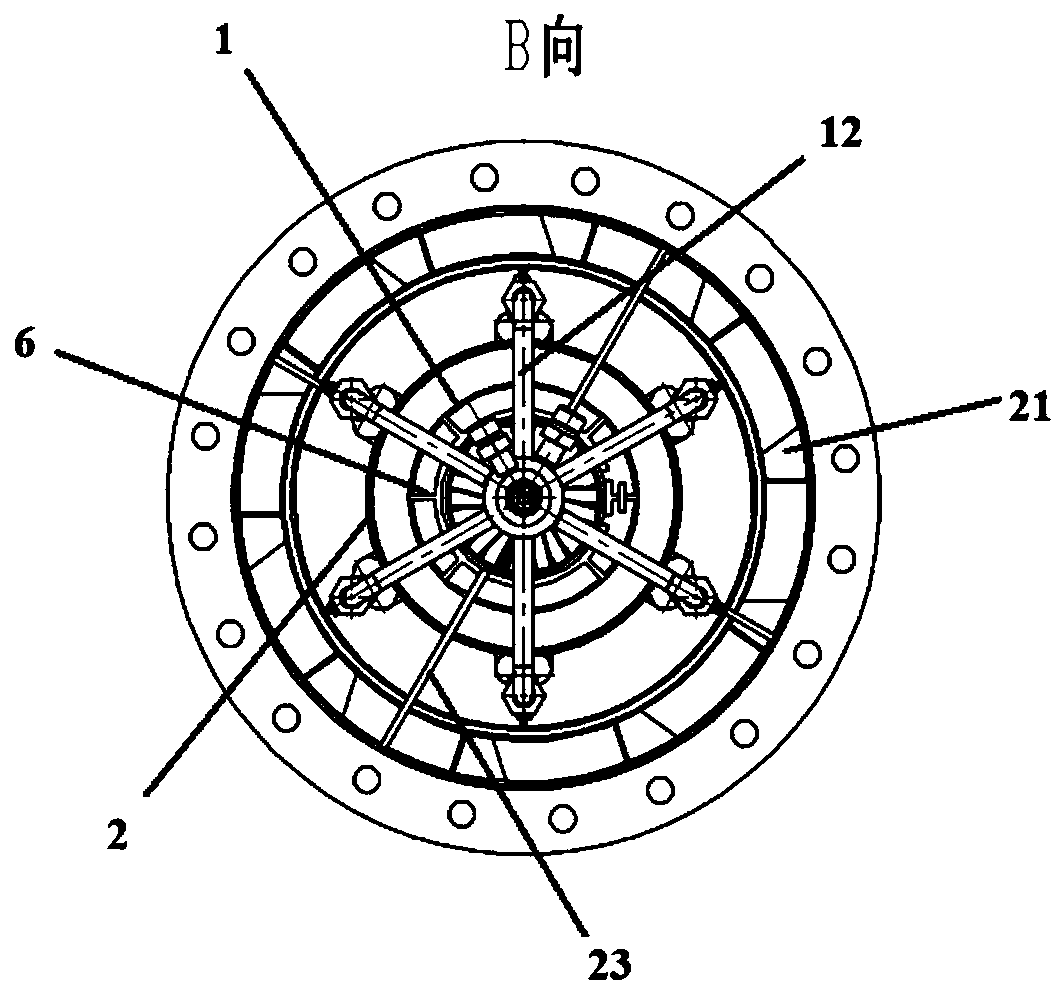

[0048] Such as Figure 1 to Figure 7 As shown, this embodiment provides a multi-nozzle alcohol-based burner, including an air duct outer pipe 4, one end of the air duct outer pipe 4 is a burner nozzle, the other end is a connecting end and is welded with a connecting flange, so as to be connected with the combustion air duct Road connection; multi-stage air duct pipes are coaxially arranged inside the air duct outer pipe 4, and the most central air duct pipe is the first-level air duct pipe 1, and the second-level air duct pipe is sleeved outside the first-level air duct pipe 1 2. An ignition device, an air duct swirler 5 and an annular gap air distributor 6 are provided at the entrance of the primary air duct pipe 1, and a central nozzle 7 is provided on the inner ring of the air duct swirler 5, and the central nozzle 7 is connected with a The central branch pipe 8; the primary air duct pipe, ignition device, air duct swirler and annular air distributor form the central combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com