Feces treatment system and electrolytic public toilet

A technology for feces treatment and public toilets, which is applied in sludge treatment, waterway systems, biological sludge treatment, etc., can solve the problems of low efficiency of fecal water treatment, long treatment time, complex structure, etc., and achieves simple structure and treatment process. Short, water-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

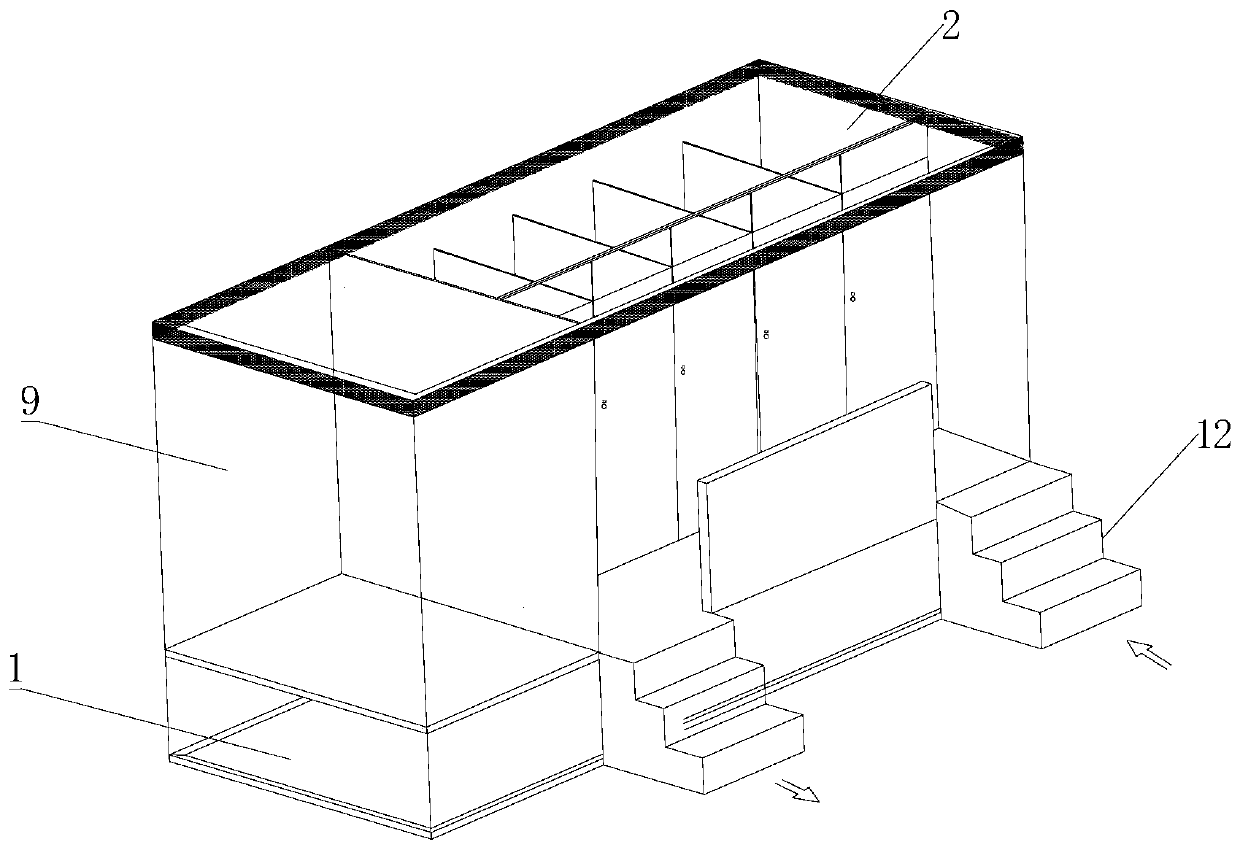

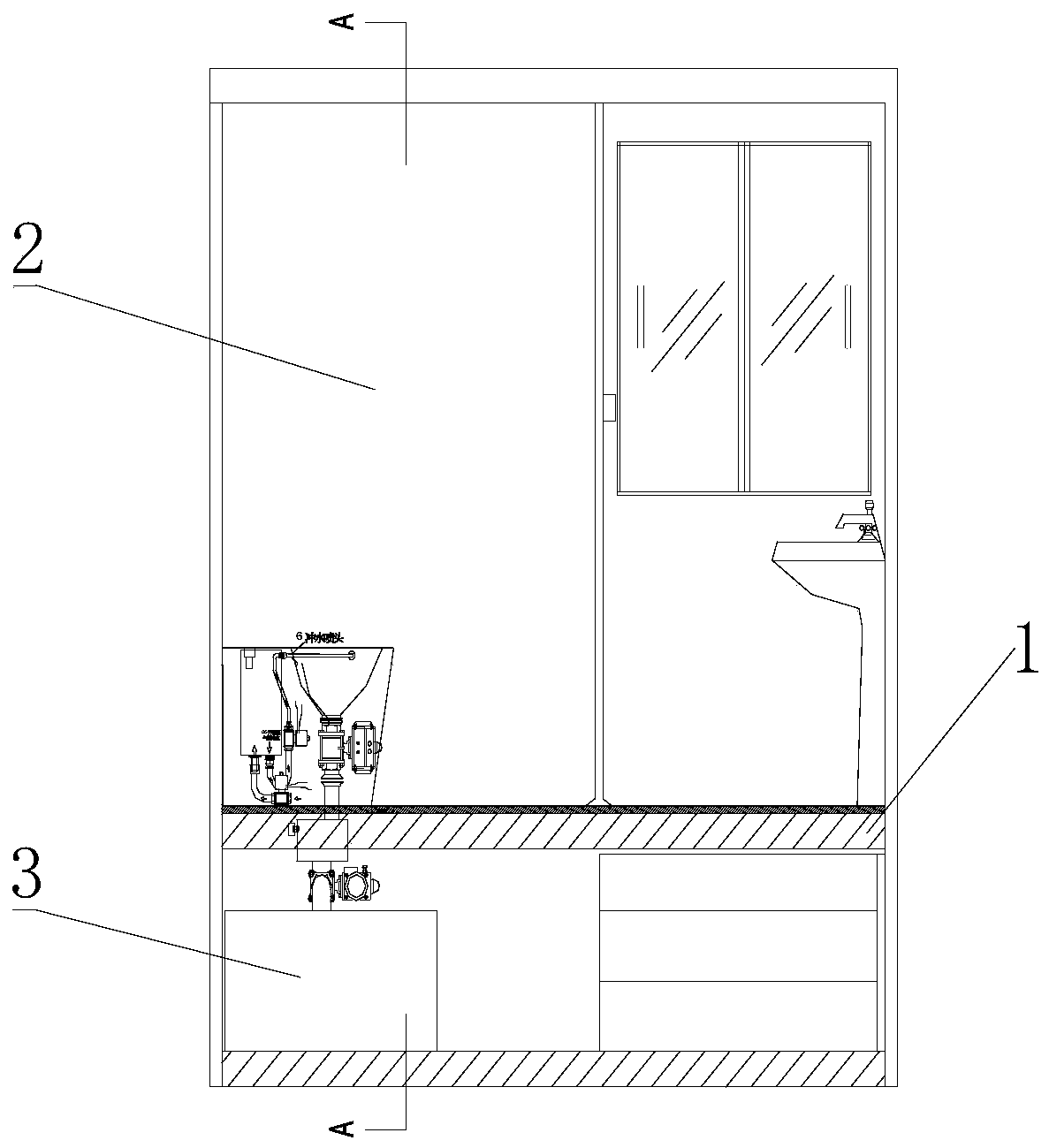

[0043] like Figure 1-Figure 6As shown, an electrolytic public toilet includes: a movable base 1, a plurality of toilets 2 arranged on the base 1, and a feces collection box 3 arranged in the base 1 and connected to each toilet 2 It is characterized in that the base is also provided with an electrolysis box 4, a collection box 5 after electrolysis, a press machine 6, a membrane filter box 7 and a reuse water tank 8, and the excrement water in the excrement collection box 3 passes through the The electrolysis tank 4 , the post-electrolysis collection tank 5 , the press machine 6 and the membrane filtration tank 7 are sequentially processed into reclaimed water and enter the reuse water tank 8 for recycling.

[0044] Wherein, the base 1 is a steel box structure, and the electrolysis box 4 , the post-electrolysis collection box 5 , the press machine 6 and the membrane filtration box 7 are all arranged in the base 1 . An equipment room 9 is also provided on the base 1 and the reu...

Embodiment 2

[0057] A feces treatment system, characterized in that it comprises: a feces collection box, an electrolysis box, a collection box after electrolysis, a squeezer, a membrane filtration box, and a reuse water tank, and the feces water in the stool collection box passes through the electrolysis box, The post-electrolysis collection tank, the press machine and the membrane filtration tank are sequentially processed into reclaimed water which enters the recycled water tank for recycling.

[0058] In the excrement treatment system provided in this embodiment, the structures and connections of the header tank, electrolysis tank, post-electrolysis collection tank, squeezer, membrane filtration tank, and reused water tank are consistent with those in Embodiment 1, and will not be repeated here. The difference is that the feces disposal system is applied to fixed public toilets. In other embodiments, the manure treatment system can also be applied to the treatment of poultry and livest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com