Double-hole lithium ion cover plate and rocking-chair type liquid injection device and method thereof

A liquid injection device, lithium ion technology, applied in the direction of battery cover/end cover, electrical components, electrochemical generators, etc., can solve the problem that the vacuum is too small, the gas cannot be completely discharged, the liquid injection yield is low, and the battery is less liquid, etc. problem, to solve the risk of battery bulging, improve the injection accuracy, and reduce the effect of battery bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

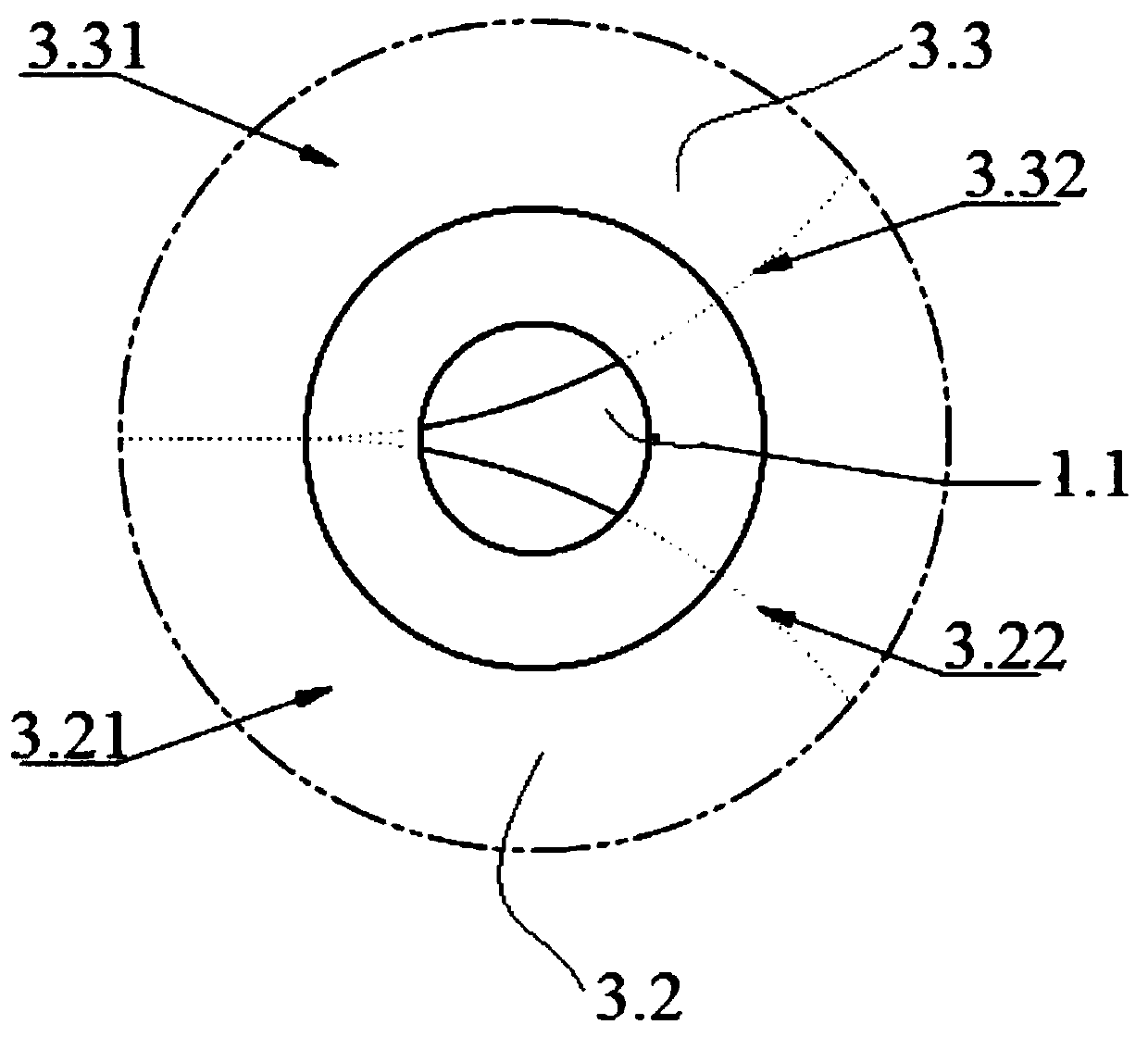

[0050] like figure 1 As shown, the present invention discloses a double-hole lithium ion cover plate, which is mainly used for injecting electrolyte solution into the inner cavity of the battery; specifically, first liquid injection holes are respectively set at both ends of the cover plate 1 1.1. The second liquid injection hole 1.2. The present invention does not make specific requirements for the aperture of the injection hole. Generally, it is flexibly designed according to the battery capacity and the volume of the liquid injection cup; each of the liquid injection holes is located in the A pole core of the lithium-ion battery 3.2 Directly above the part connected to the B pole core 3.3, specifically, combined with figure 1 and figure 2 It can be seen that each of the liquid injection holes is located directly above the R angle 3.22 of the A pole core and the R angle 3.32 of the B pole core. Point 1.2; the positive and negative tabs are welded to the cover plate 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com