PERC battery cleaning and texturing process and system

A process and battery technology, applied in the field of PERC battery cleaning and texturing process and system, can solve the problems of reducing the type and amount of chemicals used, reducing the overall time of the cleaning and texturing process, and uniform pyramid size, etc., to achieve types and Less usage, shorter overall time, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

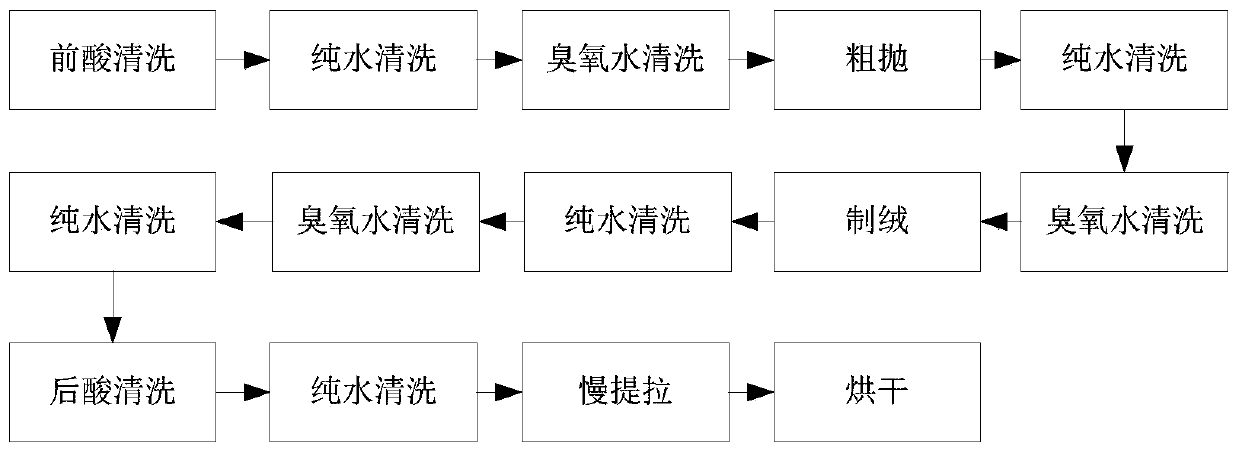

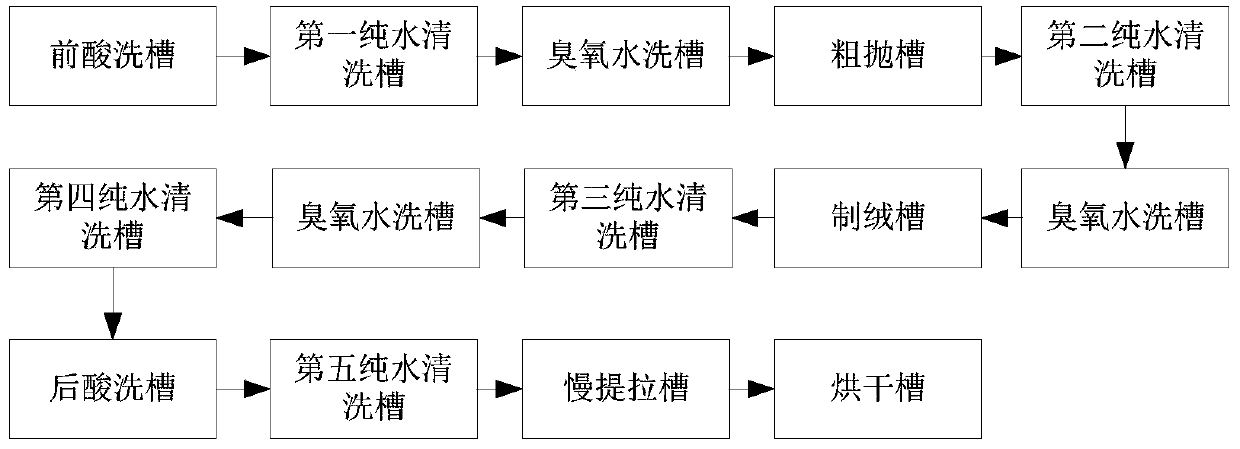

[0034] Such as figure 1 Shown, a kind of PERC cell cleaning texturing process comprises the following steps:

[0035] Step (1), put the original silicon wafer into the pickling tank for pre-acid cleaning treatment. Wherein, the volume concentration of HF is 5%. The volume concentration of HCL is 5%, and the rest is pure water. The temperature of acid cleaning is 20°C, the time of acid cleaning is 60S, and circular bubbling is carried out at the same time.

[0036] Step (2), putting the silicon chip pickled in step (1) into the first pure water cleaning tank for pure water cleaning. The pure water cleaning time is 60S, and the temperature is 25°C.

[0037] Step (3), performing the first ozone water cleaning treatment on the silicon wafer after step (2) cleaning with pure water in the ozone water washing tank. The ozone concentration in the ozone water cleaning tank was 25 ppm. The temperature is 20°C, and the washing time with ozone water is 150S.

[0038] In step (4), t...

Embodiment 2

[0052] A PERC battery cleaning and texturing process, comprising the following steps:

[0053] Step (1), put the original silicon wafer into the pickling tank for pre-acid cleaning treatment. The volume concentration of HF is 5%. The volume concentration of HCL is 5%, and the rest is pure water. The temperature of the acid cleaning is 20°C, the time of the acid cleaning is 60S, and circular bubbling is carried out at the same time.

[0054] Step (2), putting the silicon chip pickled in step (1) into the first pure water cleaning tank for pure water cleaning. The pure water cleaning time is 60s, and the temperature is 25°C.

[0055] Step (3), performing the first ozone water cleaning treatment on the silicon wafer after step (2) cleaning with pure water in the ozone water washing tank. The ozone concentration in the ozone water cleaning tank is 30ppm; the temperature is 20°C, and the ozone water cleaning time is 200S.

[0056] In step (4), the silicon wafers cleaned with o...

Embodiment 3

[0069] A PERC battery cleaning and texturing process, comprising the following steps:

[0070] Step (1), put the original silicon wafer into the pickling tank for pre-acid cleaning treatment. The volume concentration of HF is 5%. The volume concentration of HCL is 5%, and the rest is pure water. The temperature of acid cleaning is 20°C, the time of acid cleaning is 60S, and circular bubbling is carried out at the same time.

[0071] Step (2), putting the silicon chip pickled in step (1) into the first pure water cleaning tank for pure water cleaning. The pure water cleaning time is 60S, and the temperature is 25°C.

[0072] Step (3), performing the first ozone water cleaning treatment on the silicon wafer after step (2) cleaning with pure water in the ozone water washing tank. The ozone concentration in the ozone water cleaning tank is 35ppm; the temperature is 20°C, and the ozone water cleaning time is 240S.

[0073] In step (4), the silicon wafers cleaned with ozone wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com