Corrected binary particle gap accumulation design method based on mutual influence among particles

A technology of mutual influence and particle accumulation, applied in the field of material accumulation, can solve the problems of insufficient contact, large void ratio of binary particle accumulation system, etc., and achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

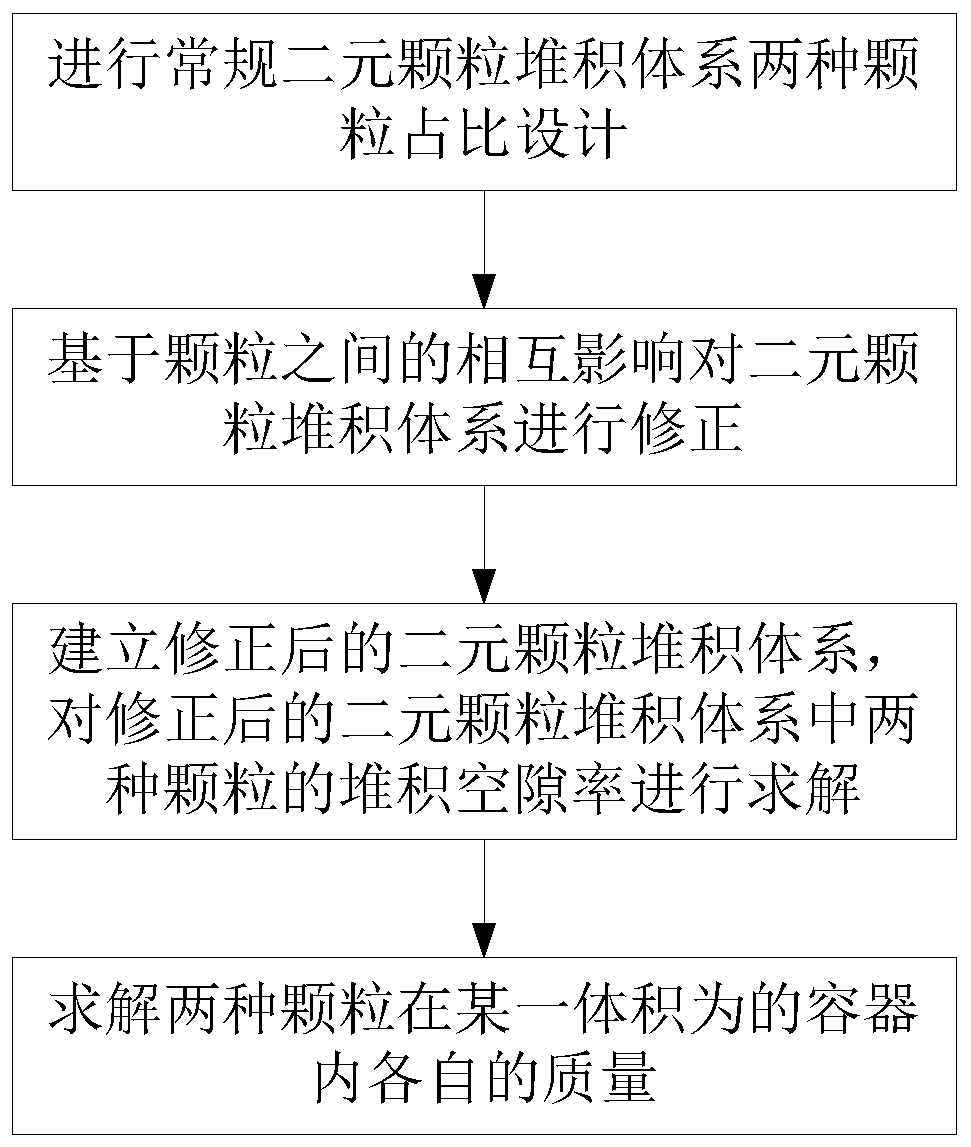

Method used

Image

Examples

Embodiment

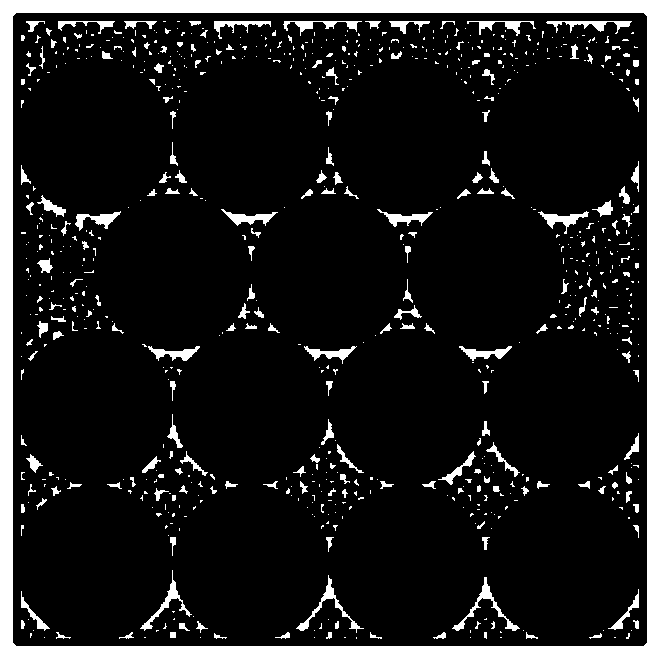

[0074] According to the inventive method to total volume be 1m 3 The void accumulation of the binary particles is designed, the particle size of the large particle and the small particle are 10mm and 1mm respectively; the void ratio of the one-dimensional accumulation is 0.5 and 0.43 respectively, and the apparent density is 2727.5kg / m3 3 、2607kg / m 3 . Conventional binary particle void packing considers that the gaps between particles are as follows: figure 2 The ideal state shown is that the small particles fully fill the voids of the large particles, and there is no influence between the two. The mass of large and small particles m 1 、m 2 They are:

[0075] m 1 =1×(1-0.5)×2727.5=1363.75kg

[0076] m 2 =1×0.5×(1-0.43)×2607=742.995kg

[0077] According to the total volume and the volume of large and small particles, the porosity of the binary particle void packing system is calculated as 0.215.

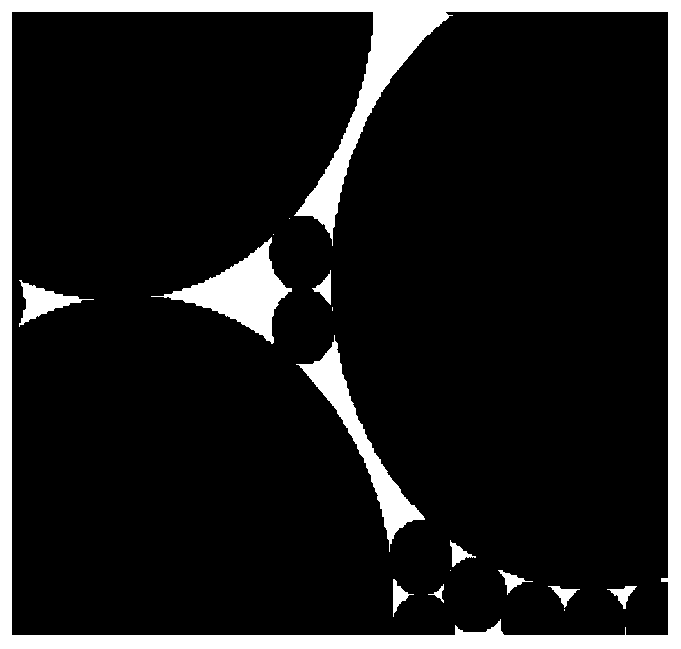

[0078] However, due to the interaction between particles, such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com