Intelligent defect identification scanner and using method thereof

A technology of defect identification and scanner, which is applied in the direction of optical testing defect/defect, instrument, scientific instrument, etc. It can solve the problems of low efficiency and high production cost, and achieve the effect of reducing labor cost, convenient single-person operation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

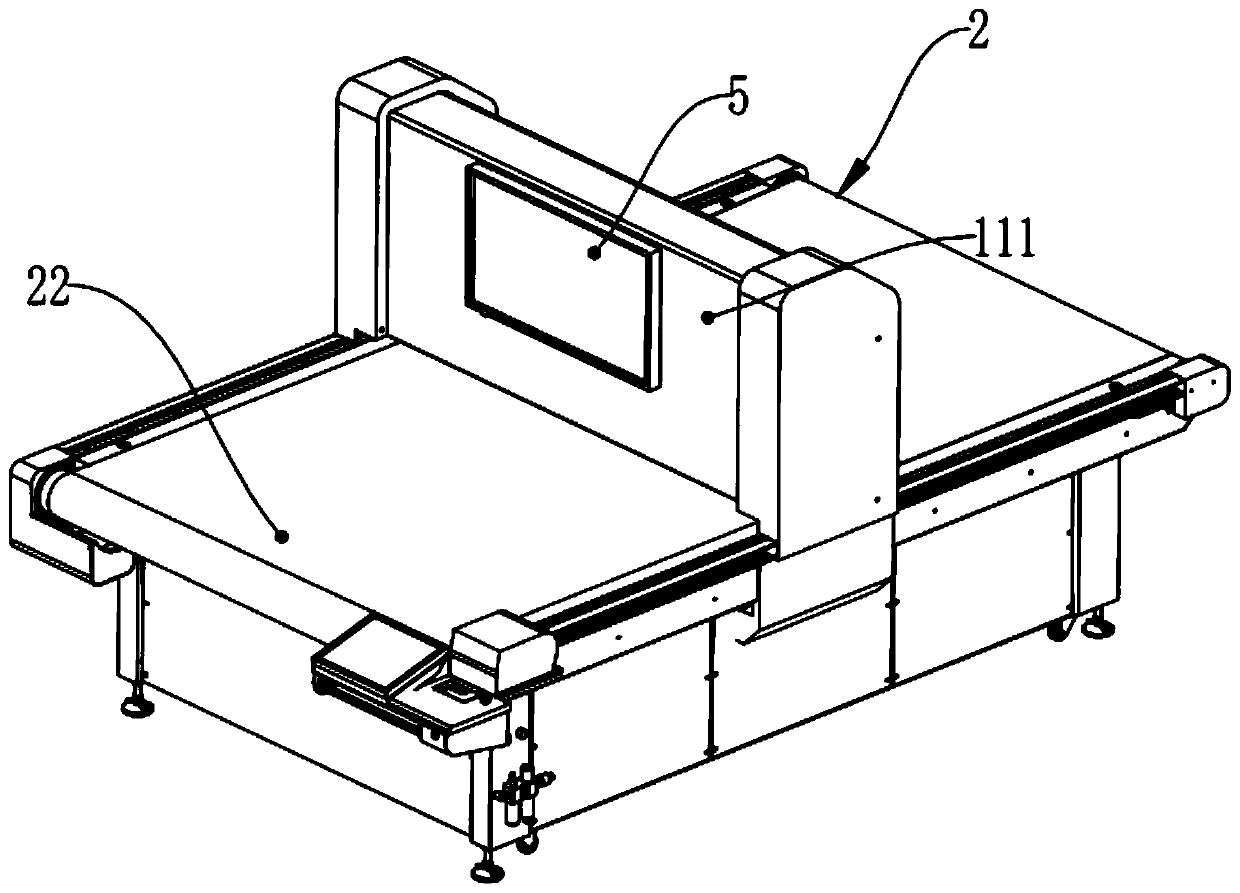

[0030] Such as Figure 1-4 As shown, a defect scanner of the embodiment includes a detection platform 1, a conveying device 2, a light source 3 and a plurality of detection devices 4;

[0031] The conveying device 2 is arranged on the detection platform 1, and the conveying device 2 is used to convey the raw material to the bottom of the detection device 4 along the detection platform 1;

[0032] The detection platform 1 is provided with a mounting bracket 11, a plurality of the detection devices 4 are arranged linearly on the mounting bracket 11, the detection end of the detection device 4 is vertically set downward, and the light source 3 is set On the mounting bracket 11, the detection device 4 is an industrial camera;

[0033] It also includes an information processing device, the signal acqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com