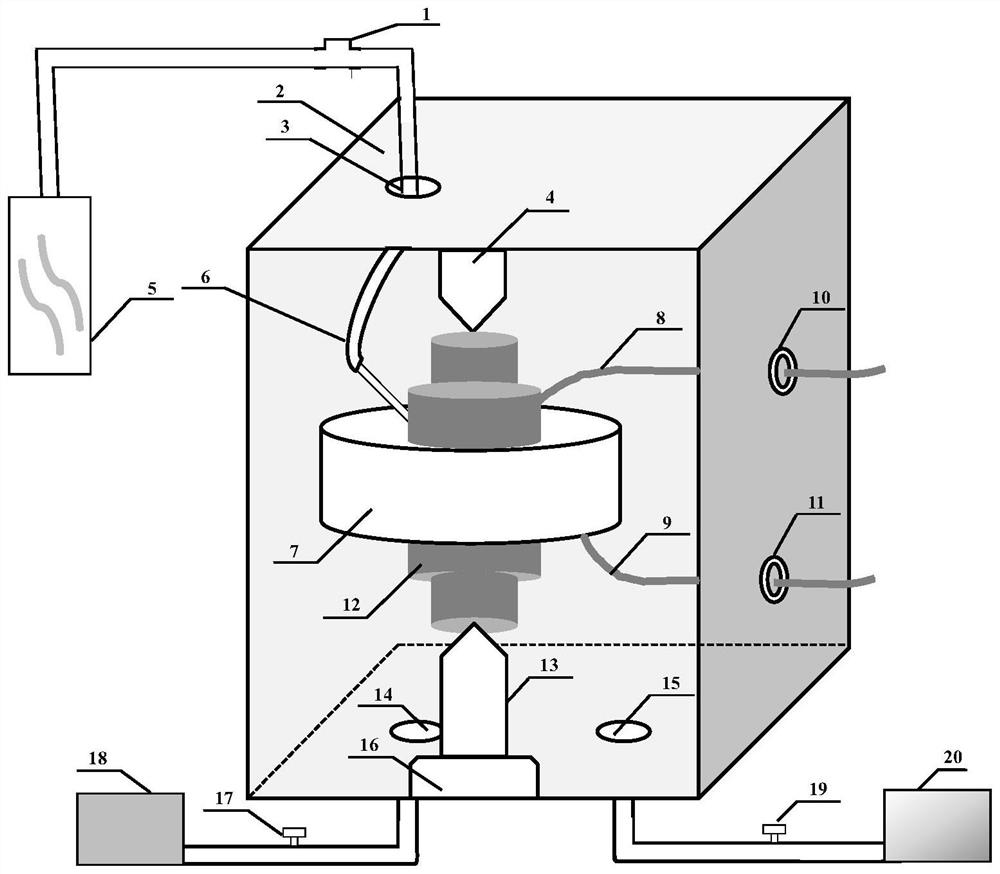

A thermal fatigue test device

A test device, thermal fatigue technology, applied in measurement devices, greenhouse gas reduction, instruments, etc., can solve the problems of uneven sample injection, cumbersome experimental operation, different cooling rates, etc., to improve reliability and uniform injection angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

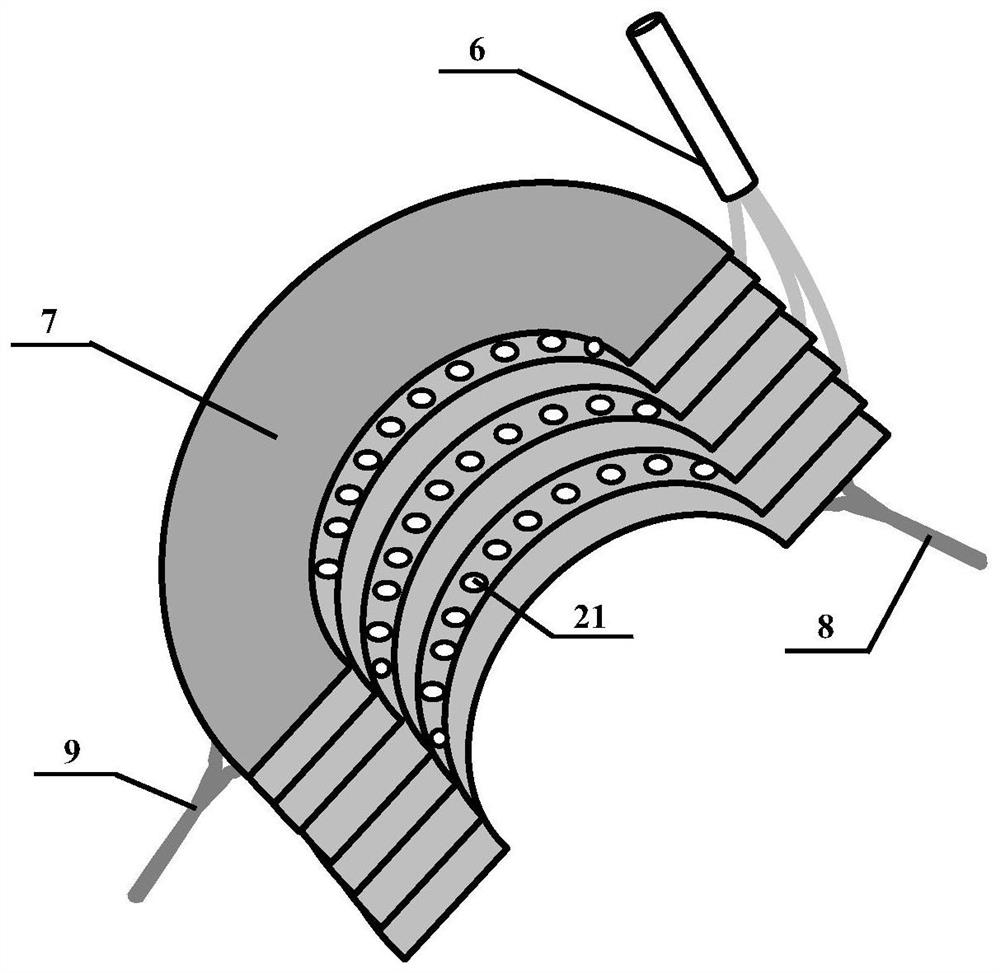

Method used

Image

Examples

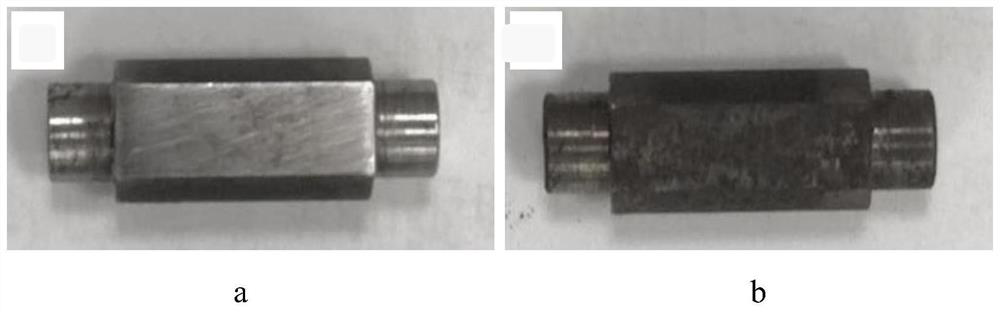

Embodiment 1

[0028] In the case where the number of tests is small and the experimental samples need to be removed for observation every few heating cycles, in order to facilitate repeated sampling operations, the vacuum cover can be directly sprayed on the sample through the ventilation coil to achieve the The oxidation protection of the sample avoids the trouble of repeated vacuuming. The specific process is as follows. The commonly used aluminum alloy die-casting mold steel SKD 61 is used as the test sample. The upper and lower thimbles are used to fix the test sample in the heating coil. By adjusting the positions of the upper and lower thimbles, the test sample is placed in the center of the heating coil. Open the air inlet valve, spray protective gas (nitrogen or argon) through the air inlet of the gas cooling part, and maintain the low-pressure air injection state to create a local protective gas atmosphere around the test sample inside the heating coil. Then, the heating coil was ...

Embodiment 2

[0030] When the number of tests is large and repeated sampling is not required for observation, it is recommended to use a vacuum hood to protect the samples from oxidation. The specific process is as follows: take SKD 61 steel for aluminum alloy die-casting molds as the test sample, use the upper thimble and the lower thimble to fix the test sample in the heating coil, and adjust the position of the upper thimble and the lower thimble to place the test sample on the heating coil. Right in the center. Close the intake valve and exhaust valve, open the exhaust valve and vacuum system, evacuate the vacuum cover to a vacuum state, close the exhaust valve and vacuum system. Open the air inlet valve, fill the protective gas (nitrogen or argon) through the air inlet of the gas cooling part until the pressure in the vacuum hood reaches 1 atmosphere, then open the exhaust valve, and energize the heating coil, and heat for 5s to make The temperature of the test sample was raised to 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com