Anti-falling bolt and nut for electric power iron tower and working method thereof

A power tower, bolt and nut technology, applied in the direction of nuts, bolts, screws, etc., can solve the problems of falling off, loose bolts and nuts, hidden dangers, etc., and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to more clearly and clearly illustrate the specific implementation objectives and implementation modes of the present invention, the technical solution of the present invention will be fully described below, and the described embodiments are part of the embodiments of the present invention, rather than all embodiments. On the premise of no creative work, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

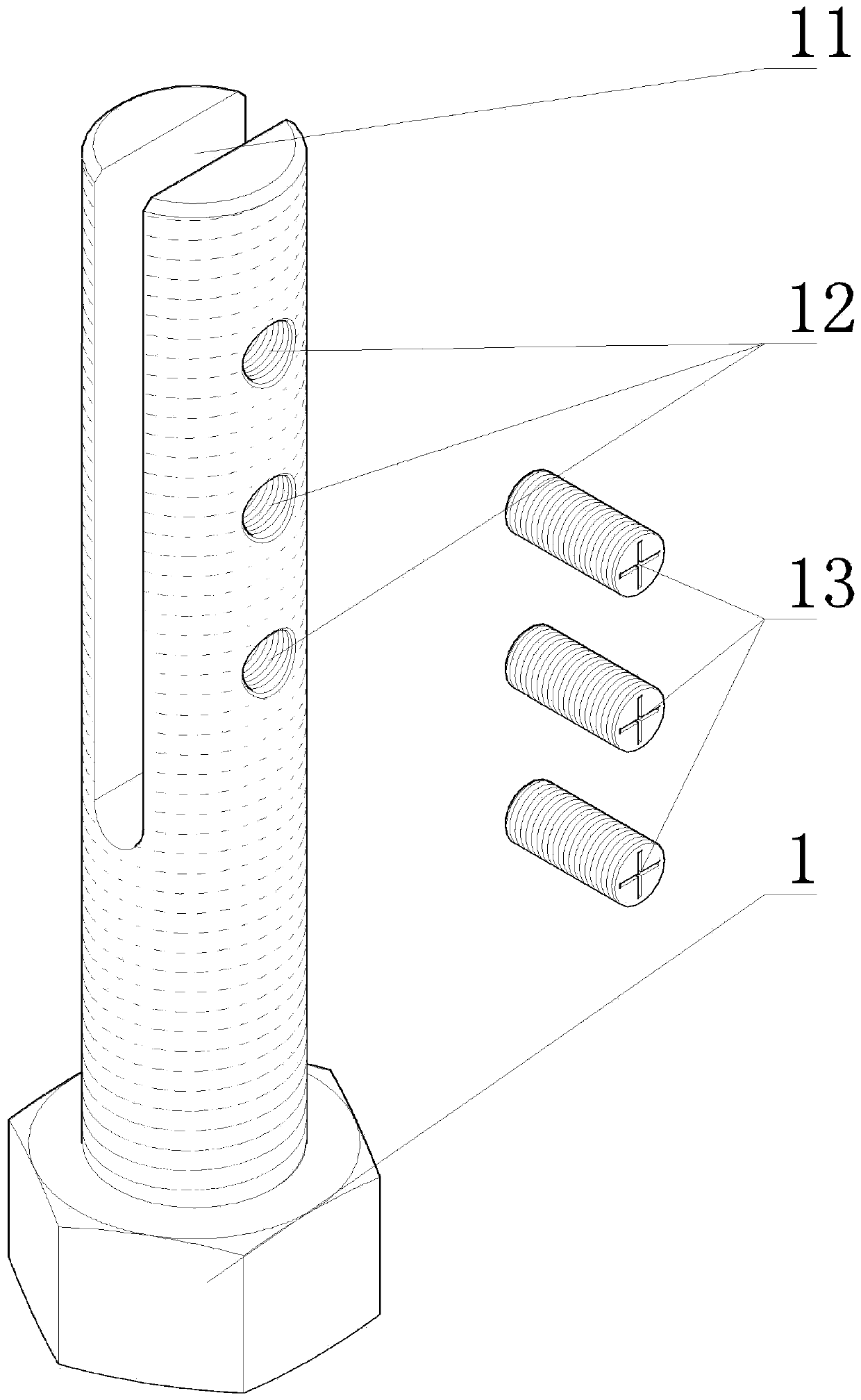

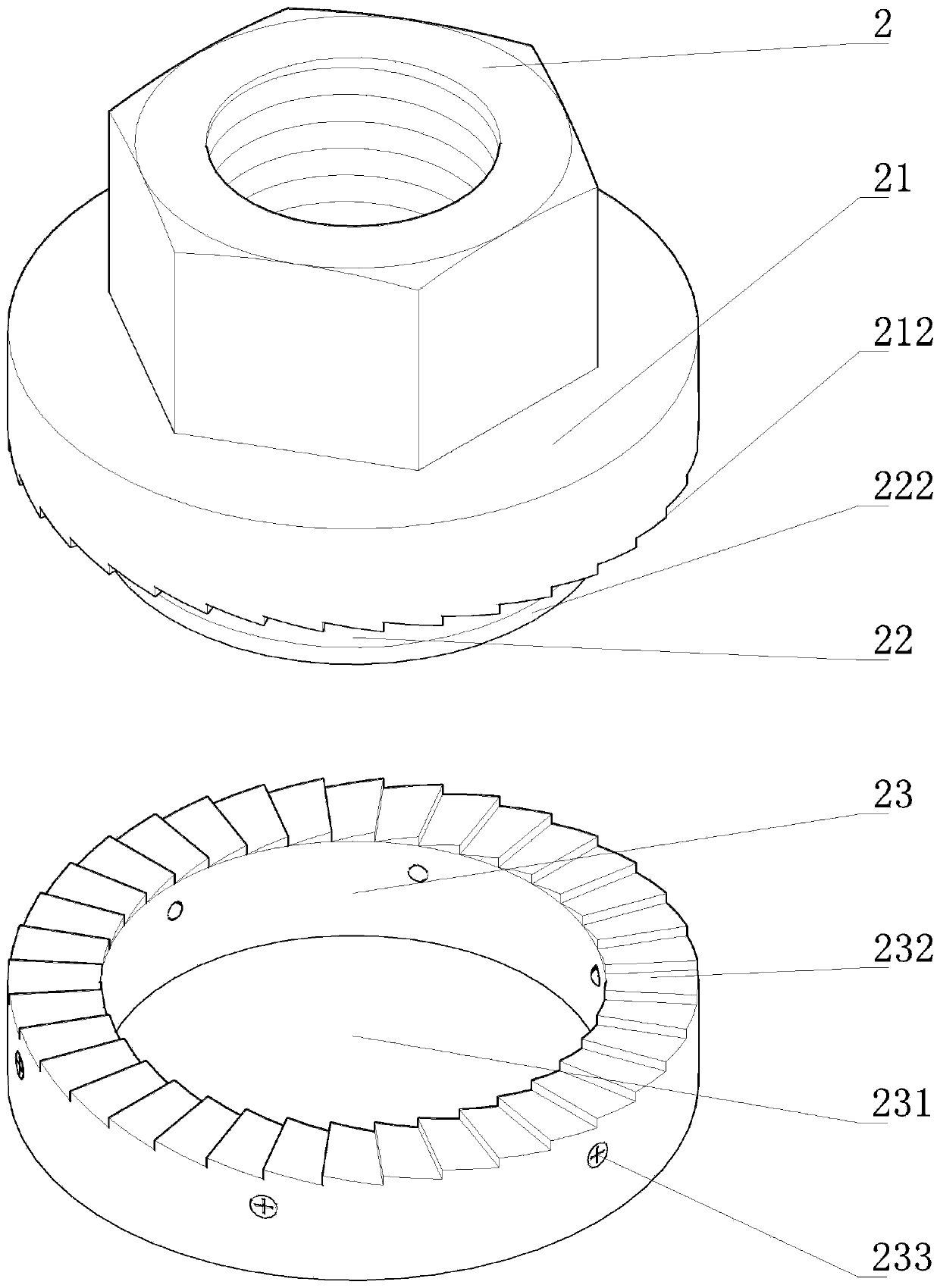

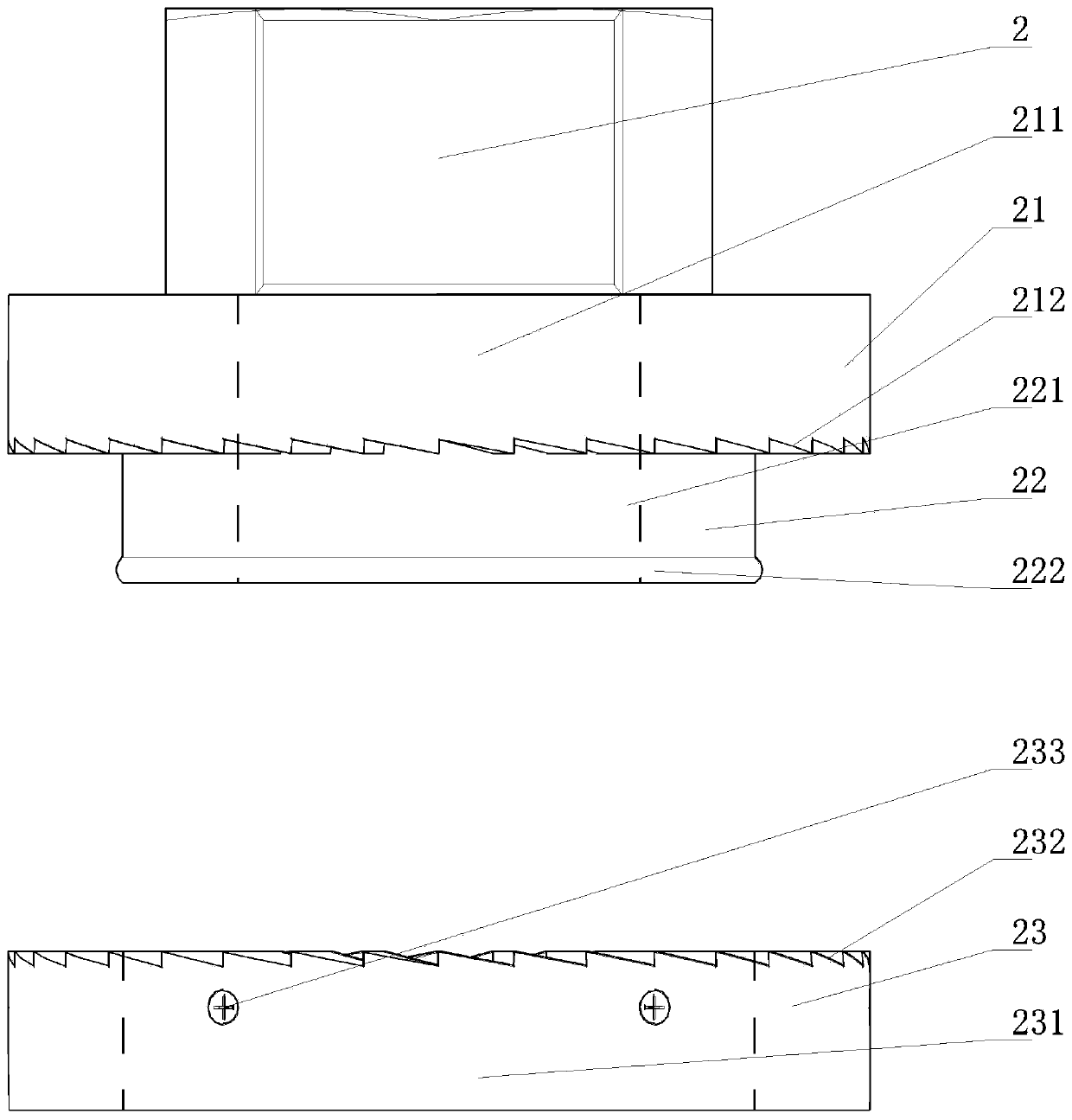

[0058] An anti-falling bolt and nut for an electric power tower of the present invention comprises a bolt 1 and a nut 2:

[0059] Such as figure 1 As shown, the screw rod of the bolt 1 is provided with a groove 11 through its central axis, so that the screw rod of the bolt 1 forms a "U"-shaped structure, and the bolt 1 on the side of the groove 11 is provided with a plurality of screw holes. The hole 12 is screwed with a limit screw 13 inside the screw hole 12, and the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com