Exhaust brake valve and air compressor combined auxiliary braking system and method

An exhaust brake valve and auxiliary braking technology, which is applied in the charging system, engine components, machine/engine, etc., can solve the problems of insufficient auxiliary braking power and low auxiliary braking power, and improve energy utilization rate. , The effect of improving auxiliary braking power and improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

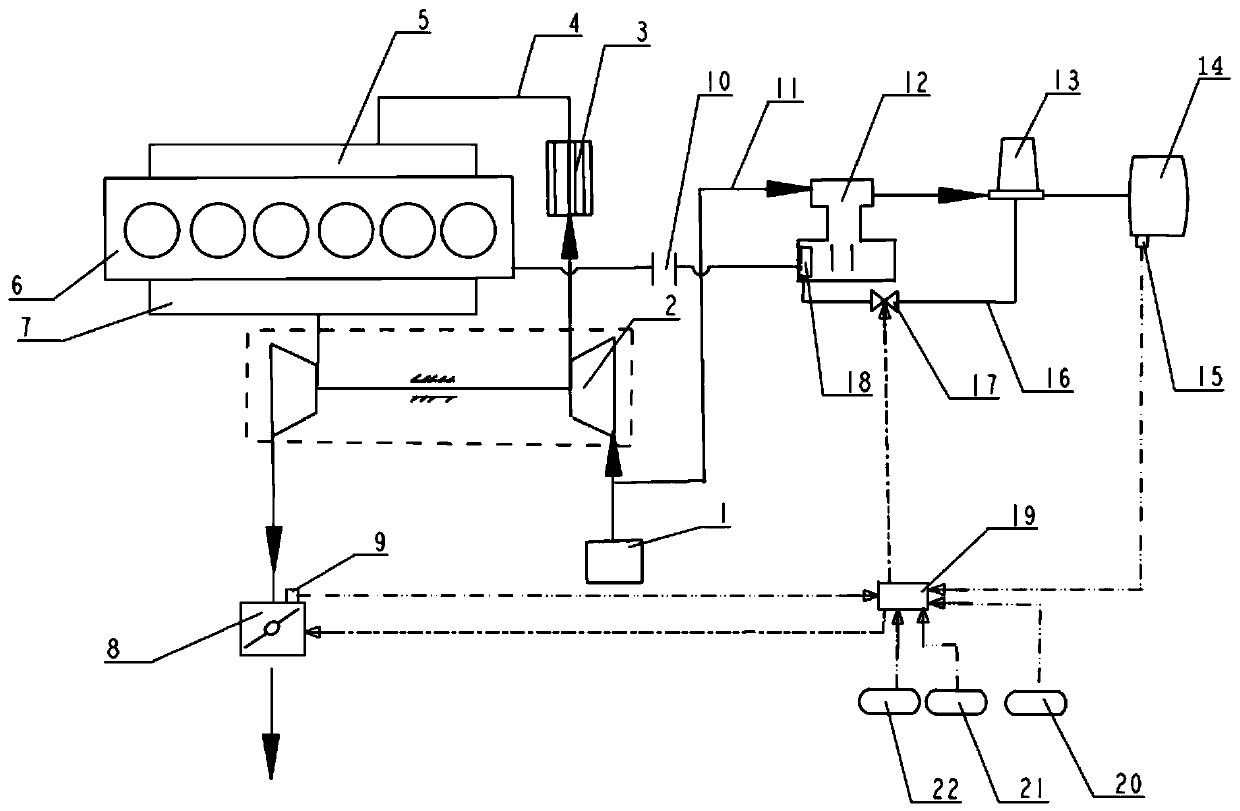

[0021] The present invention relates to an exhaust brake valve and an air compressor combined auxiliary brake system, such as figure 1 As shown, it includes a supercharger 2, an intercooler 3 and an engine body 6, the first output end of the supercharger 2 is connected to the engine intake pipe 5 of the engine body 6 through the intercooler 3, and the engine exhaust of the engine body 6 The output end of the manifold 7 is connected to the second input end of the supercharger 2, and it is characterized in that it also includes an exhaust brake valve 8, a transmission gear 10, an air compressor 12, a dryer 13, an air storage tank 14, an electromagnetic Valve 17, ECU 19, auxiliary brake relay 20, brake pedal position sensor 21 and vehicle speed sensor 22, wherein the first input end of supercharger 2 is used to introduce air, and the second output end of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com