Deformed steel bar semi-grout sleeve joint

A semi-grouting sleeve and threaded steel technology, which is applied to structural elements, building components, building reinforcements, etc., can solve the problem of low bonding strength between grouting cement and threaded steel and the inner wall of the fixed sleeve, detachment or relative sliding at the joint, Problems such as cracking at the connection of the support column to achieve the effect of increasing the stable connection, preventing excessive rigidity, and preventing slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

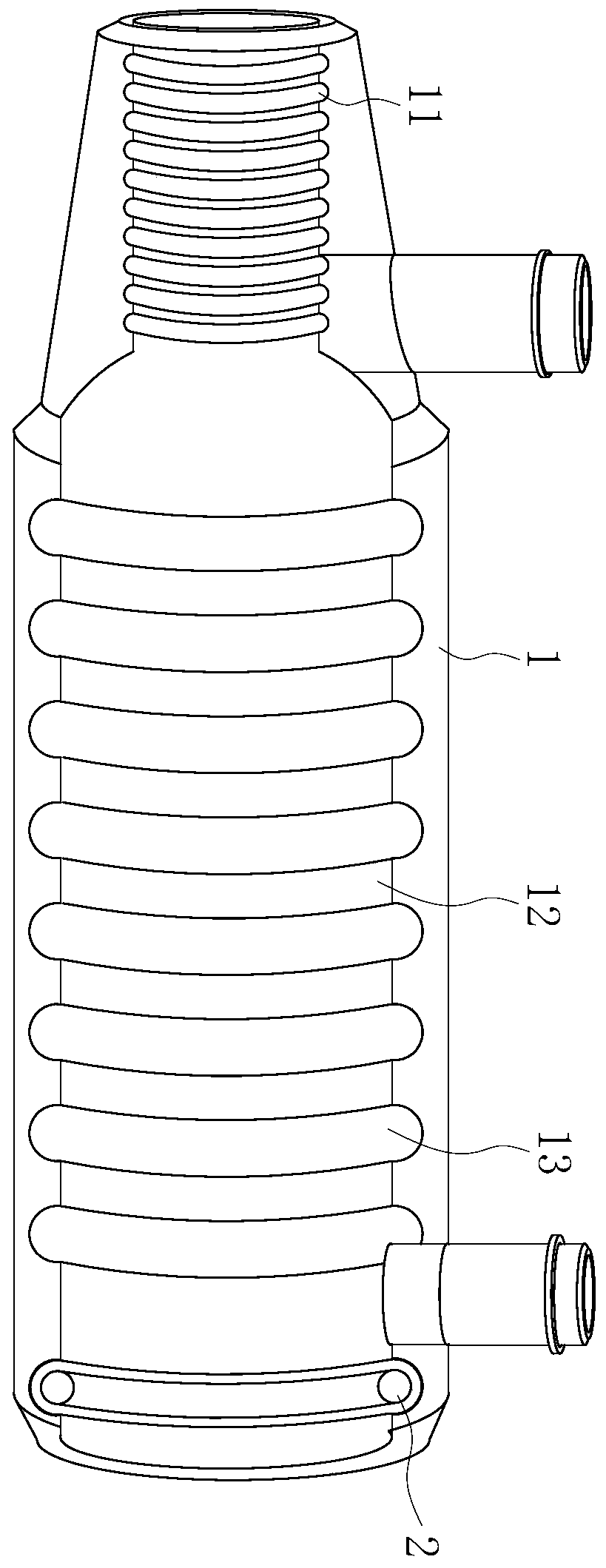

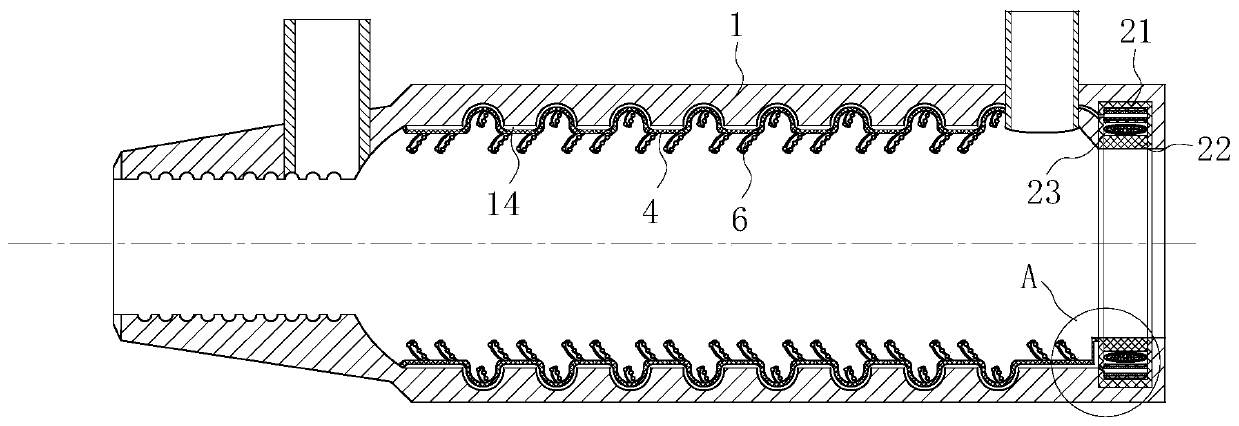

[0022] use Figure 1-Figure 4 A threaded steel semi-grouting sleeve joint according to an embodiment of the present invention is described as follows.

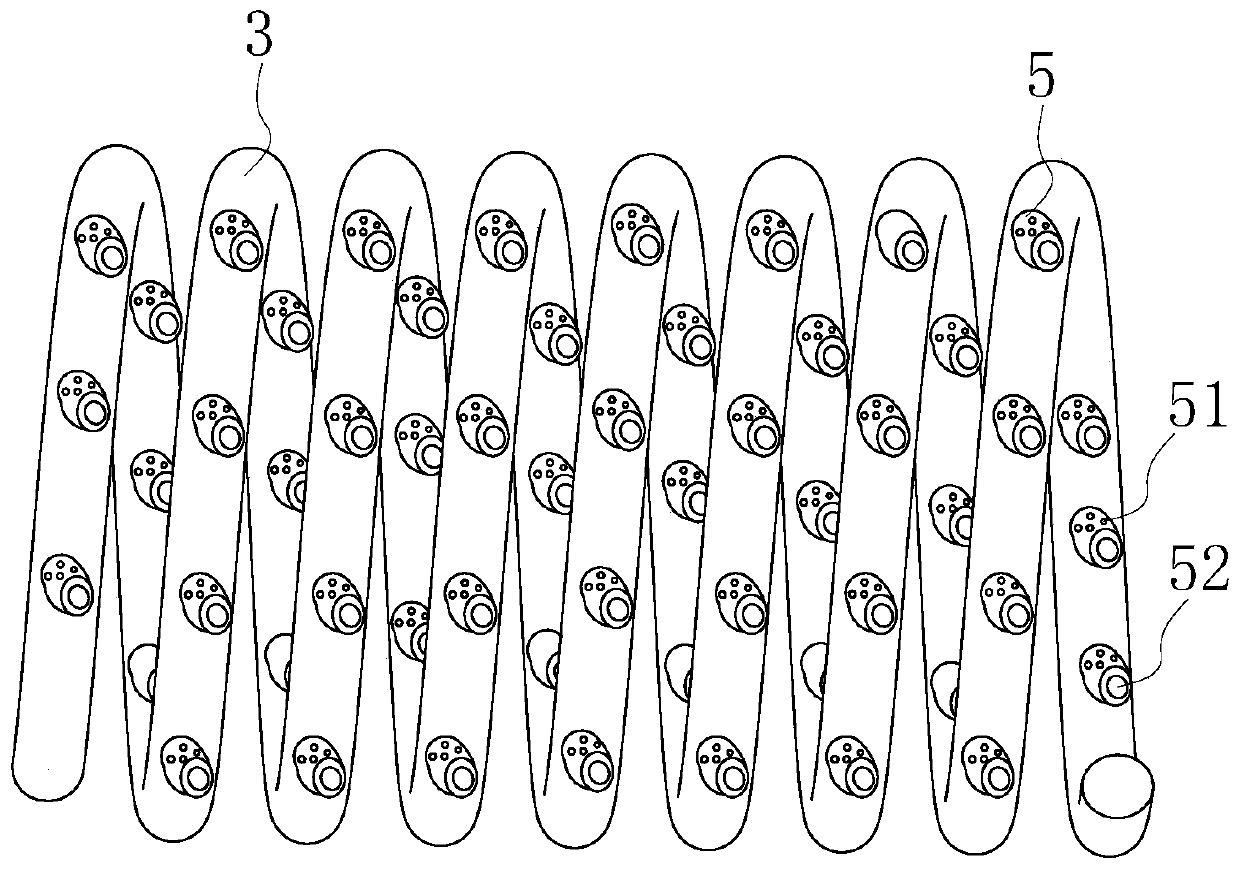

[0023] Such as figure 1 and figure 2As shown, a threaded steel semi-grouting sleeve joint according to the present invention includes a fixed sleeve 1; one end of the fixed sleeve 1 is provided with a tapered threaded hole 11, and one end of the fixed sleeve 1 is provided with a grouting port. And the other end of the fixed sleeve 1 is provided with a slurry outlet, and the end of the fixed sleeve 1 is provided with an annular sealing ring 2; the fixed sleeve 1 is provided with a fixed cavity 12, and the side wall of the fixed cavity 12 is provided with a spiral Groove 13; said spiral groove 13 is helically inserted with an elastic spiral skeleton 3; an elastic fiber layer 4 is arranged between the elastic spiral skeleton 3 and the spiral groove 13; the inner wall and outer wall of the elastic spiral skeleton 3 are inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com