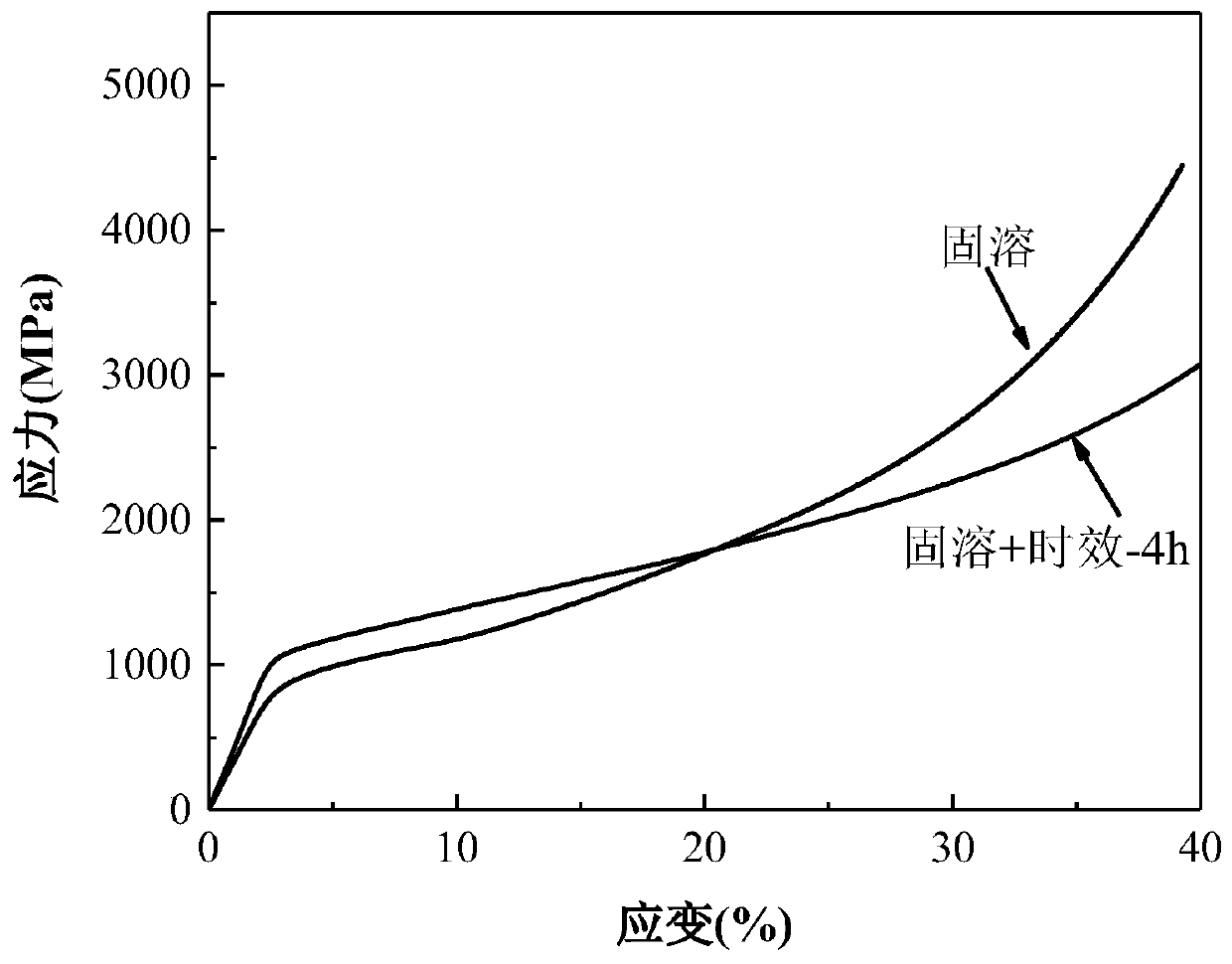

Low-elasticity-modulus and high-strength spinodal decomposition type Zr-Nb-Ti alloy material and preparation method thereof

A low elastic modulus, zr-nb-ti technology, applied in the field of medical zirconium alloys, can solve the problems of low elastic modulus, and achieve the effect of low elastic modulus, good ductility, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Weighing: Weigh raw materials: made of 30% Ti, 30% Nb, and Zr in the atomic percentage of elements, and weigh high-purity titanium grains, high-purity niobium grains, and high-purity zirconium grains respectively. The purity of high-purity titanium particles, high-purity niobium particles, and high-purity zirconium particles is not less than 99.99%.

[0046] (2) Melting: put the raw materials weighed in step (1) into a vacuum arc melting furnace for melting, the melting current is 220A, and the melting suspension time is 65s. In order to improve the accuracy and uniformity of the composition, the ingot needs to be smelted six times repeatedly to obtain the ingot.

[0047] (3) Suction casting: putting the ingot obtained in step (2) into a vacuum arc melting furnace for suction casting to obtain a zirconium alloy rod.

[0048] (4) Microstructure control: the suction casting rod obtained in step (3) is subjected to solution treatment, and in the solution treatment ste...

Embodiment 2

[0051] (1) Weigh each component: Weigh the raw material: it is made of 33% Ti, 31% Nb, and the balance is Zr according to the atomic percentage of the elements. Weigh high-purity titanium grains, high-purity niobium grains, and high-purity zirconium grains respectively . The purity of high-purity titanium particles, high-purity niobium particles, and high-purity zirconium particles is not less than 99.99%.

[0052] (2) Melting: put the raw materials weighed in step (1) into a vacuum arc melting furnace for melting, the melting current is 200A, and the melting suspension time is 90s. In order to improve the accuracy and uniformity of the composition, the ingot needs to be smelted six times repeatedly to obtain the ingot.

[0053] (3) Suction casting: putting the ingot obtained in step (2) into a vacuum arc melting furnace for suction casting to obtain a zirconium alloy rod.

[0054] (4) Microstructure control: the suction casting rod obtained in step (3) is subjected to solut...

Embodiment 3

[0057] (1) Weigh each component: Weigh the raw material: it is made of 30% Ti, 30% Nb, and the balance is Zr according to the atomic percentage of the elements. Weigh high-purity titanium grains, high-purity niobium grains, and high-purity zirconium grains respectively . The purity of high-purity titanium particles, high-purity niobium particles, and high-purity zirconium particles is not less than 99.99%.

[0058] (2) Melting: put the raw materials weighed in step (1) into a vacuum arc melting furnace for melting, the melting current is 230A, and the melting suspension time is 85s. In order to improve the accuracy and uniformity of the composition, the ingot needs to be smelted six times repeatedly to obtain the ingot.

[0059] (3) Suction casting: putting the ingot obtained in step (2) into a vacuum arc melting furnace for suction casting to obtain a zirconium alloy rod.

[0060] (4) Microstructure control: the suction casting rod obtained in step (3) is subjected to solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com