Finish grinding device of steel plate

A fine grinding and steel plate technology, which is applied in the direction of grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve the problems of insufficient grinding, corrosion, time-consuming and labor-intensive problems, and achieve the effect of reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

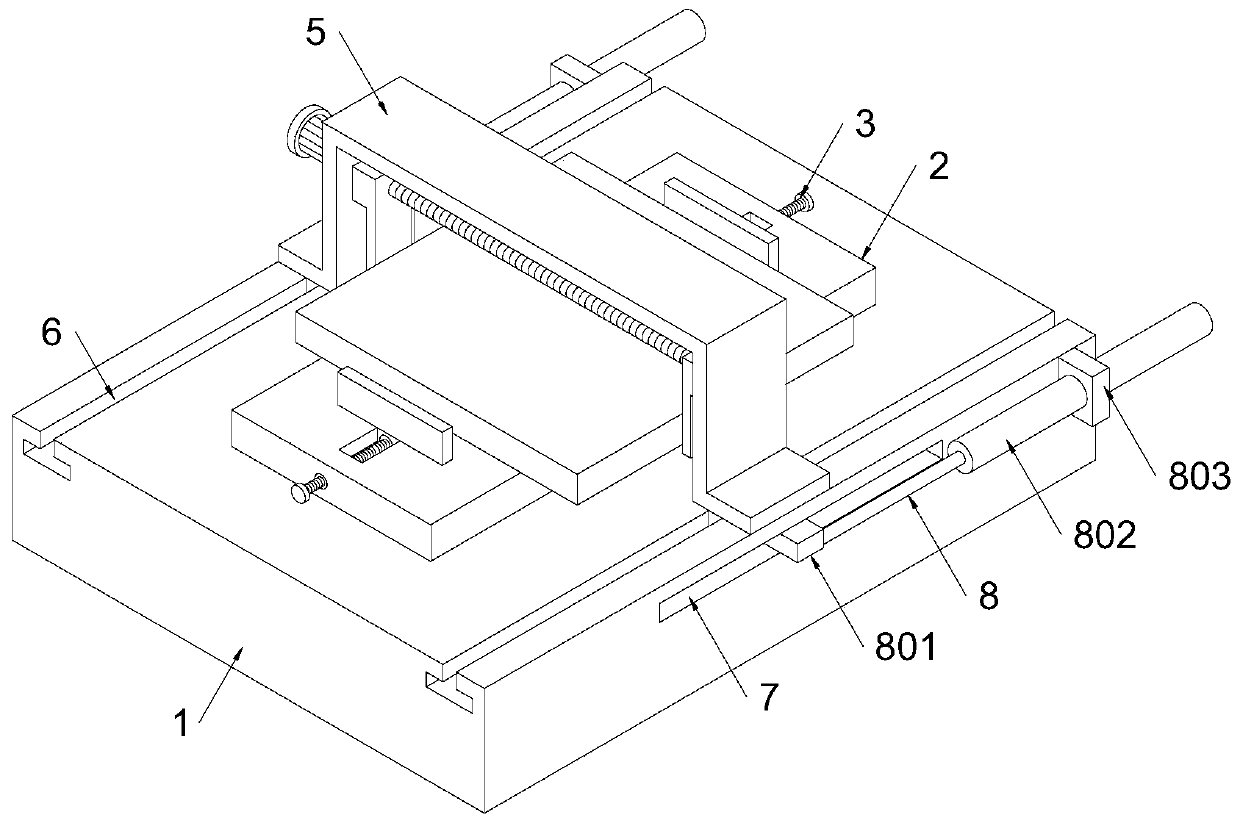

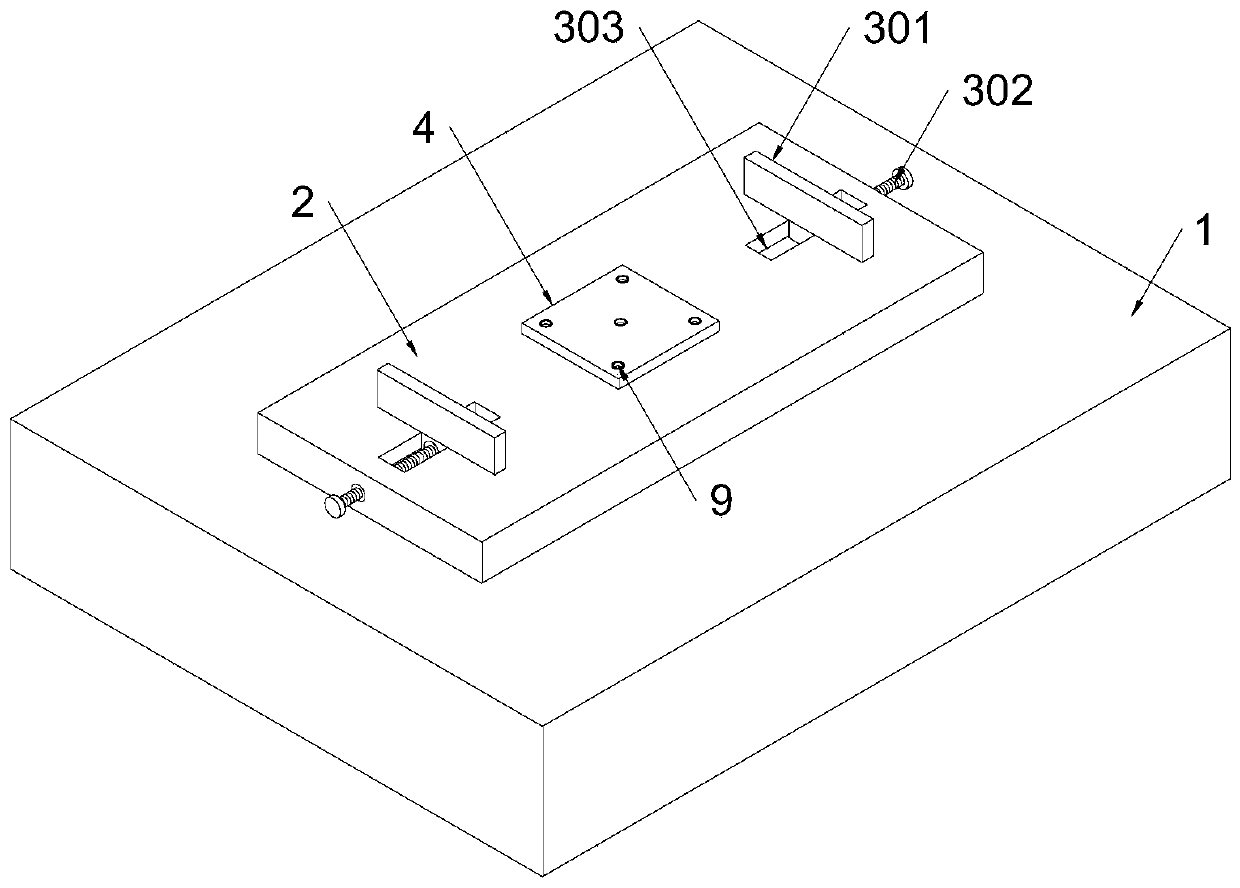

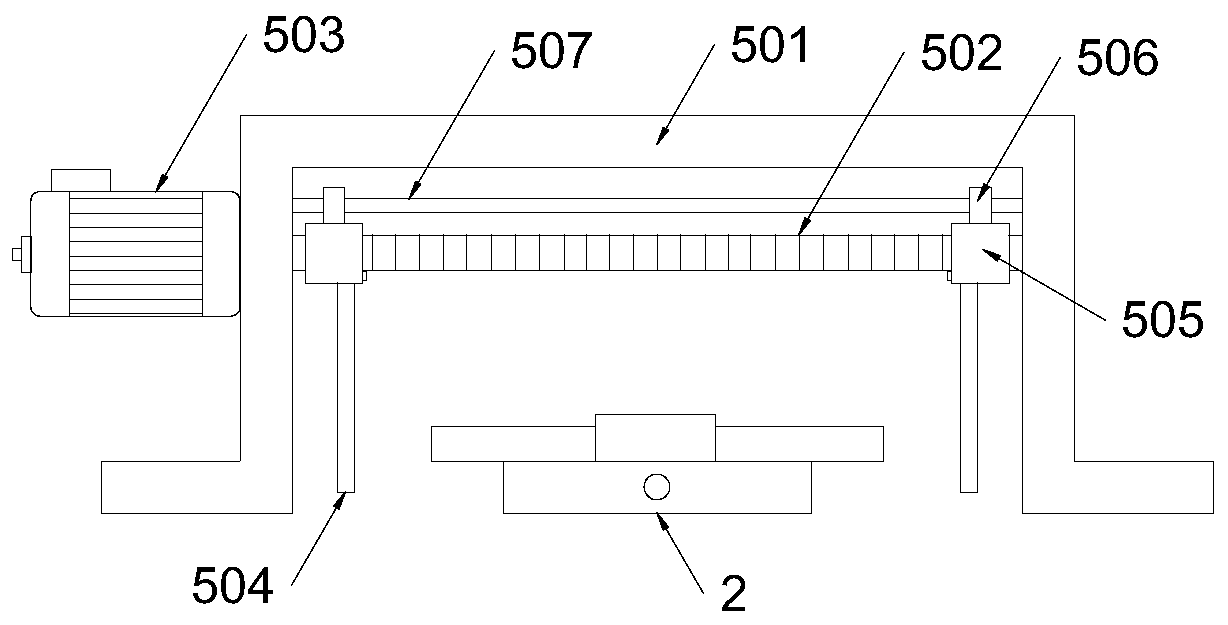

[0022] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a fine grinding device for a steel plate in the present invention includes an operating table 1 and a fixed plate 2 fixedly arranged in the middle of the top end of the operating table 1. Both sides of the top end of the fixed plate 2 are respectively symmetrically provided with clamps for clamping the steel plate. Tightening mechanism 3, the middle part of the top of the fixed plate 2 is provided with a placing plate 4 for placing the steel plate, the top of the fixed plate 2 is provided with a grinding mechanism 5 for grinding the steel plate, and both sides of the top of the console 1 are equipped with The chute 6 is an inverted T shape, and a slider is arranged in the chute 6, and the two sliders are respectively fixed on both sides of the bottom end of the grinding mechanism 5, and both sides of the console 1 are provided with the chute 6. There is a through slot 7, and a pushing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com