Method for recycling calcium-rich pyrochlore from weathered high-mud carbonate type niobium polymetallic ore

A carbonate type, polymetallic ore technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem of lack of separation process of calcium-rich pyrochlore, unrecoverable pyrochlore, and recovery rate. low problems, to achieve the effect of high grade, high recovery rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

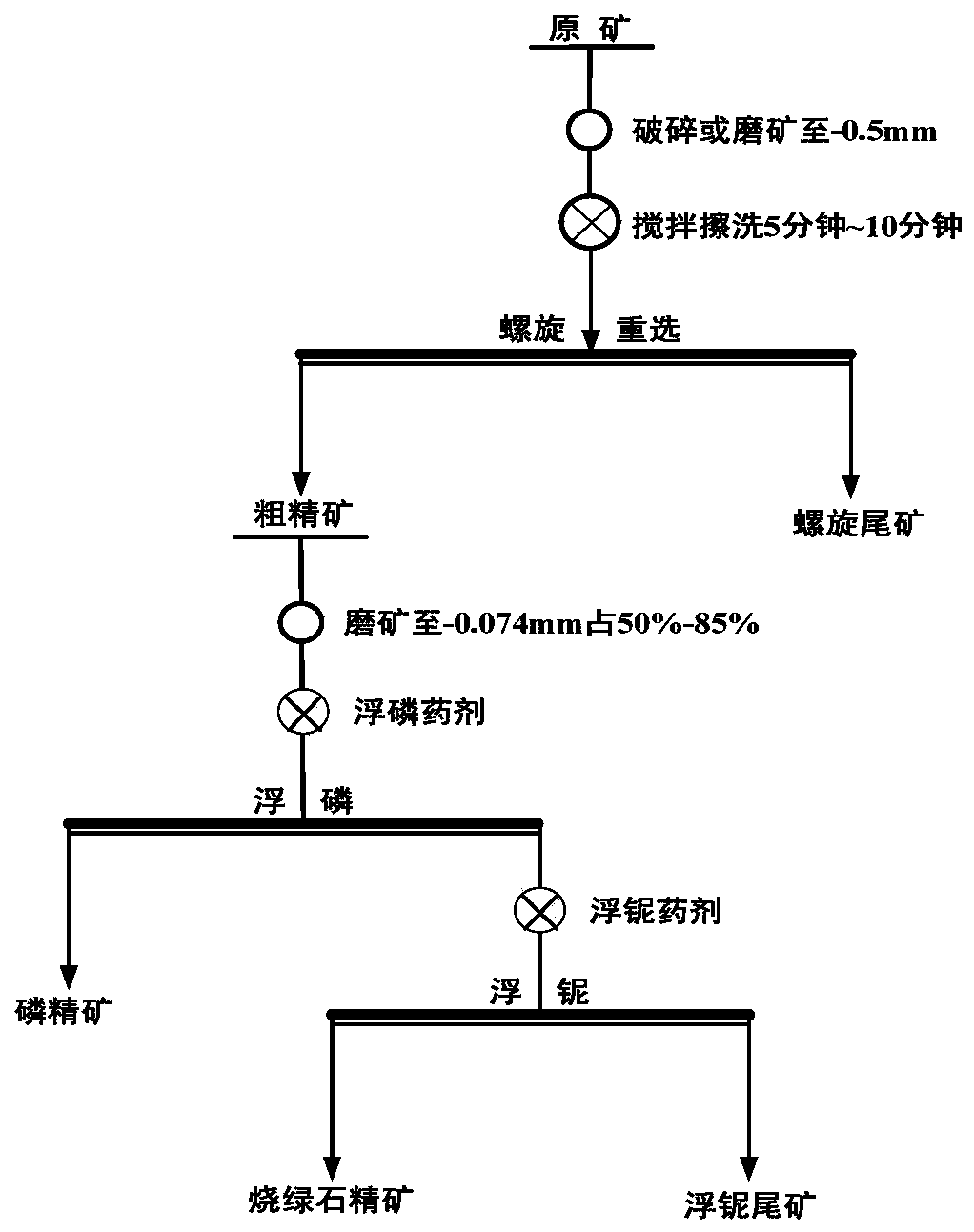

[0031] A method for recovering calcium-rich pyrochlore from weathered high-mud carbonate-type niobium polymetallic ore, comprising the steps of:

[0032] S1. Raw ore grinding to -0.5mm accounts for 92%;

[0033] S2. Add water to the product after grinding to adjust the pulp concentration to 25%, stir and scrub for 10 minutes, and carry out spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

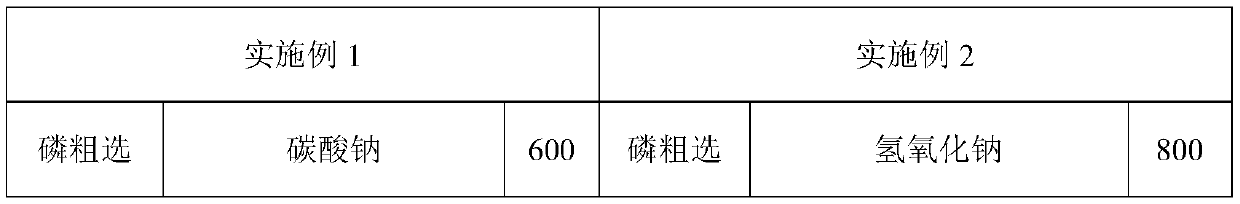

[0034] S3. Regrind the coarse concentrate to -0.074mm to account for 70%, add water to adjust the slurry to a pulp concentration of 30%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0035] S4. Concentrate the floating phosphorus tailings to a slurry concentration of 30%, add floating niobium reagents to the floating phosphorus tailings, and perform niobium flotation, niobium concentrate and floating niobium tailings.

[0036] See Table 1 for the phosphorus f...

Embodiment 2

[0038] A method for recovering calcium-rich pyrochlore from weathered high-mud carbonate-type niobium polymetallic ore, comprising the steps of:

[0039] S1. Raw ore grinding to -0.5mm accounts for 96%;

[0040] S2. Add water to the ground product to adjust the pulp concentration to 35%, stir and scrub for 8 minutes, and perform spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

[0041] S3. Regrind the coarse concentrate to -0.074mm to account for 85%, add water to adjust the slurry to a pulp concentration of 25%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0042] S4. Concentrate the floating phosphorus tailings to a pulp concentration of 35%, add floating niobium reagents to the floating phosphorus tailings, and perform niobium flotation, niobium concentrate and floating niobium tailings.

[0043] See Table 1 for the phosphorus flotation agen...

Embodiment 3

[0045] A method for recovering calcium-rich pyrochlore from weathered high-mud carbonate-type niobium polymetallic ore, comprising the steps of:

[0046] S1. Raw ore grinding to -0.5mm accounts for 90%;

[0047] S2. Add water to the product after grinding to adjust the pulp concentration to 20%, stir and scrub for 5 minutes, and carry out spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

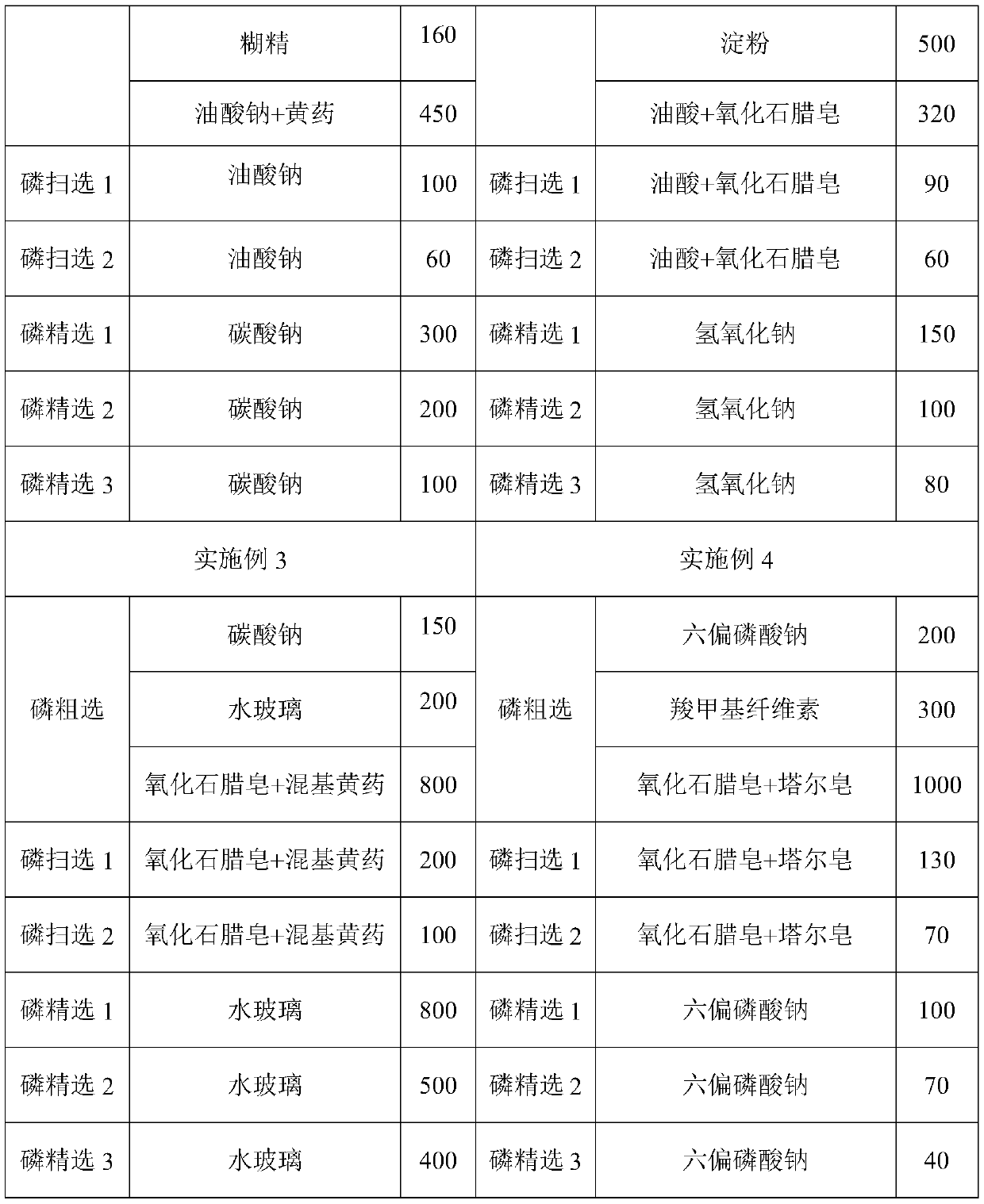

[0048] S3. Regrind the coarse concentrate to -0.074mm to account for 55%, add water to adjust the slurry to a pulp concentration of 35%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0049] S4. Concentrate the floating phosphorus tailings to a slurry concentration of 25%, add floating niobium reagents to the floating phosphorus tailings, and perform niobium flotation, niobium concentrate and floating niobium tailings.

[0050] See Table 1 for the phosphorus fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com