A kind of sulfonated polyphenol nanofiltration membrane and preparation method thereof

A technology of sulfonated polyphenols and sulfonated polyphenols, which is applied in the field of nanofiltration membranes, can solve the problems of low water flux of nanofiltration membranes, and achieve the effects of good anti-pollution ability, large industrialization potential, and water flux improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

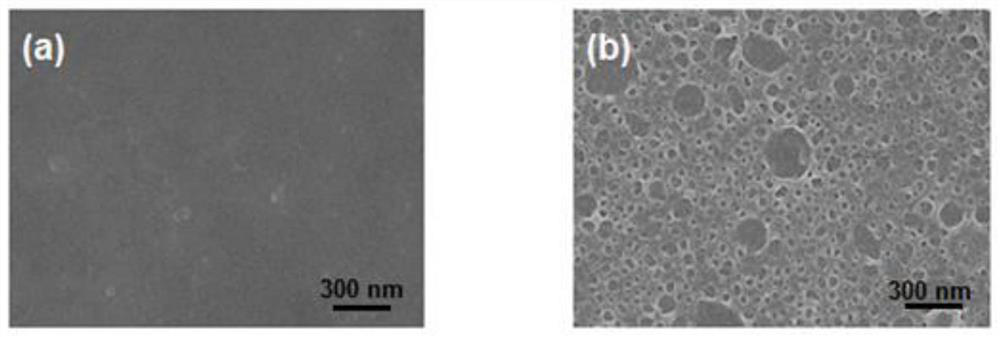

Image

Examples

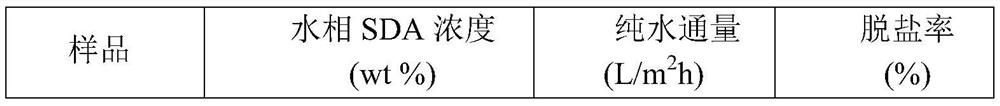

Embodiment 1

[0021] Dissolve sulfonated dopamine (SDA) in a buffer solution with a pH of 8.5 at a concentration of 0.05 wt%, and ultrasonically dissolve it completely for 10 minutes; immerse the wet polyacrylonitrile support membrane after alkali treatment in the aqueous phase solution, and the immersion time for 20 minutes, take it out and dry it for use; configure the cyclohexane oil phase solution of trimesoyl chloride, the concentration is 0.15wt%; immerse the support membrane in the oil phase solution, the reaction time is 1min, take it out; put the composite membrane at 60°C Heat treatment in an oven for 30 minutes; then rinse with deionized water several times to obtain a sulfonated polyphenol nanofiltration membrane.

Embodiment 2

[0023] The difference from Example 1 is that the concentration of sulfonated dopamine (SDA) is 0.1 wt%.

Embodiment 3

[0025] The difference from Example 1 is that the concentration of sulfonated dopamine (SDA) is 0.6wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com