U-shaped thin-wall steel-prestress concrete combined bent cap and thin-wall steel tube concrete pier node structure and construction process

A thin-walled steel pipe and concrete pier technology, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems of large component cross-section, multiple reinforcements, and insufficient seismic performance, so as to achieve strong integrity, reliable force transmission, and ensure stability The effect of sex and construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

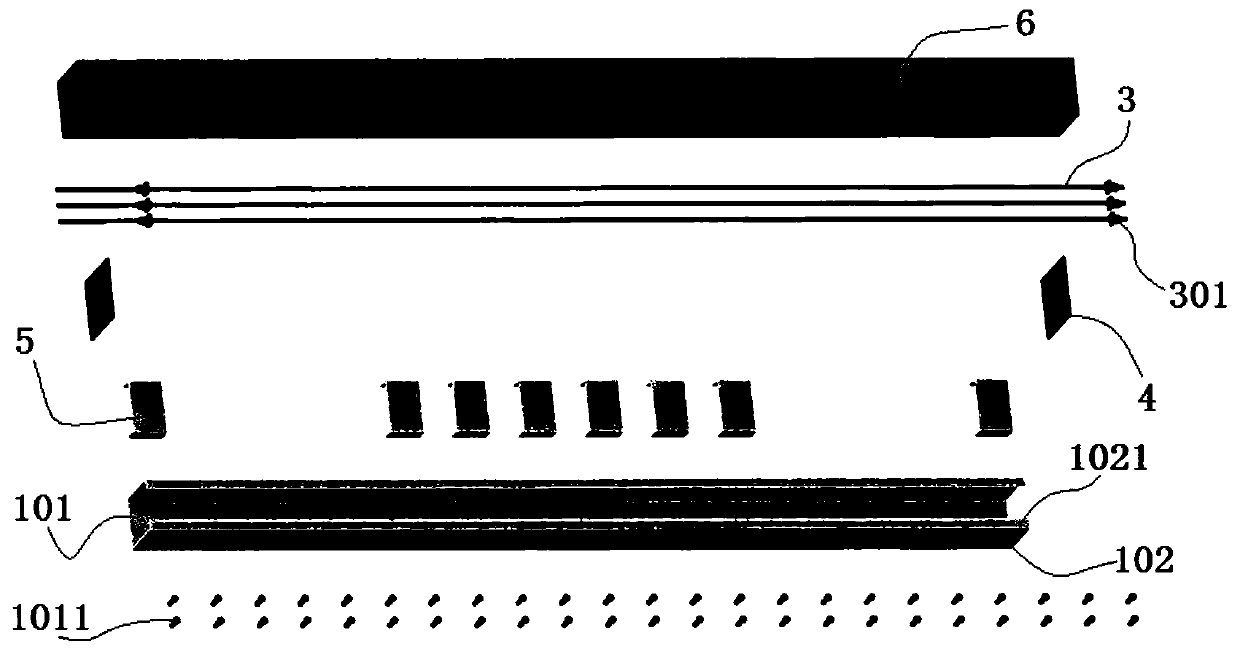

[0046] This embodiment discloses a joint structure of a U-shaped thin-walled steel-prestressed concrete composite cover beam and a thin-walled concrete-filled steel pipe pier column, including a U-shaped thin-walled steel-prestressed concrete composite cover beam and a thin-walled steel pipe concrete pier column 7 .

[0047] see Figure 9 Or 10, the upper end of the thin-walled concrete-filled steel pipe pier 7 is connected to the lower surface of the mid-span of the U-shaped thin-walled steel-prestressed concrete composite cover beam.

[0048] The U-shaped thin-walled steel-prestressed concrete composite cover beam includes U-shaped thin-walled steel plates 1 and several prestressed tendons 3 .

[0049] The U-shaped thin-walled steel plate 1 is processed by welding the thin-walled steel plate, and the processing process ensures equal strength welding. The model of the thin-walled steel plate is Q235. see figure 1 Or 2, the U-shaped thin-walled steel plate 1 is a constant-s...

Embodiment 2

[0064] This embodiment discloses a joint structure of a U-shaped thin-walled steel-prestressed concrete composite cover beam and a thin-walled concrete-filled steel pipe pier column, including a U-shaped thin-walled steel-prestressed concrete composite cover beam and a thin-walled steel pipe concrete pier column 7 .

[0065] see Figure 9 Or 10, the upper end of the thin-walled concrete-filled steel pipe pier 7 is connected to the lower surface of the mid-span of the U-shaped thin-walled steel-prestressed concrete composite cover beam.

[0066] The U-shaped thin-walled steel-prestressed concrete composite cover beam includes U-shaped thin-walled steel plates 1 and several prestressed tendons 3 .

[0067] see figure 1 , the cross-section of the U-shaped thin-walled steel plate 1 is U-shaped, with an opening at the upper end and a closed bottom at the lower end.

[0068] Below the opening is the inner cavity of the U-shaped thin-walled steel plate 1 .

[0069] The transverse ...

Embodiment 3

[0075] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to figure 1 , 6 , 7 or 8, a number of pegs 1011 are welded on the upper surface of the bottom plate 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com