Preparation method of CuFeO2 microcrystalline material of high-purity 3R delafossite structure

A technology of microcrystalline material and delafossite, which is applied in the field of preparation of high-purity 3R delafossite structure CuFeO2 microcrystalline material, can solve the problems of inconsistency, limited development and research, inaccurate chemical properties of CuFeO2, etc., and achieves low production cost , the effect of easy control of process parameters, important academic value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

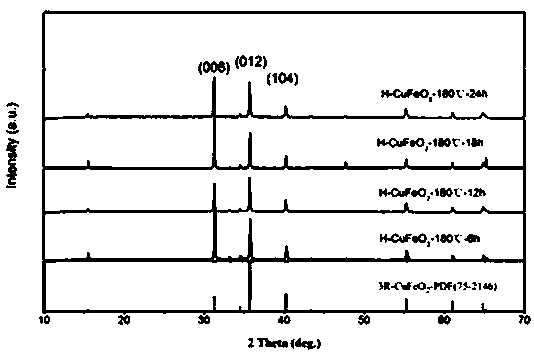

Image

Examples

Embodiment 1

[0033] A high-purity 3R delafossite structure CuFeO 2 The preparation method of microcrystalline material, concrete steps are as follows:

[0034] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 15min to dissolve, and the stirring speed of the magnetic stirrer is 300 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.5mol / L;

[0035] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 4mol / L, the dropping speed is 1.5mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 9 times the amount of the total substance of O was added, followed by ultrasonication for 12min and magnetic stirring for 12min, the ultrasonic power was 350W, and the stirring speed of the magnetic stirrer was 450 rpm;

[0036] (3) Add n-propionaldehyde dropwise to the solution in...

Embodiment 2

[0039] A high-purity 3R delafossite structure CuFeO 2 The preparation method of microcrystalline material, concrete steps are as follows:

[0040] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 12min to dissolve, and the stirring speed of the magnetic stirrer is 350 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.6mol / L;

[0041] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 2mol / L, the dropping rate is 2.5mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 6 times the amount of the total substance of O was added, followed by ultrasonication for 15min and magnetic stirring for 15min, the ultrasonic power was 300W, and the stirring speed of the magnetic stirrer was 400 rpm;

[0042] (3) Add n-propionaldehyde dropwise to the solution in ...

Embodiment 3

[0045] A high-purity 3R delafossite structure CuFeO 2 The preparation method of microcrystalline material, concrete steps are as follows:

[0046] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 11 min to dissolve, and the stirring speed of the magnetic stirrer is 400 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.7mol / L;

[0047] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 3mol / L, the dropping rate is 2mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 5 times the amount of the total substance of O was added, followed by ultrasonication for 15min and magnetic stirring for 15min, the ultrasonic power was 300W, and the stirring speed of the magnetic stirrer was 400 rpm;

[0048] (3) Add n-propionaldehyde dropwise to the solution in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com