Surface cobalt-doped zinc oxide composite material as well as preparation method and application thereof

A composite material, zinc oxide technology, applied in the field of inorganic composite materials, can solve the problems of affected internal crystal lattice structure, low surface catalytic effect, low response value and stability of ethanol gas, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

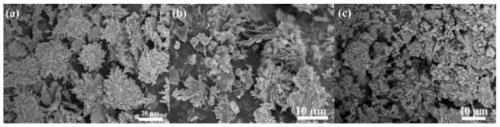

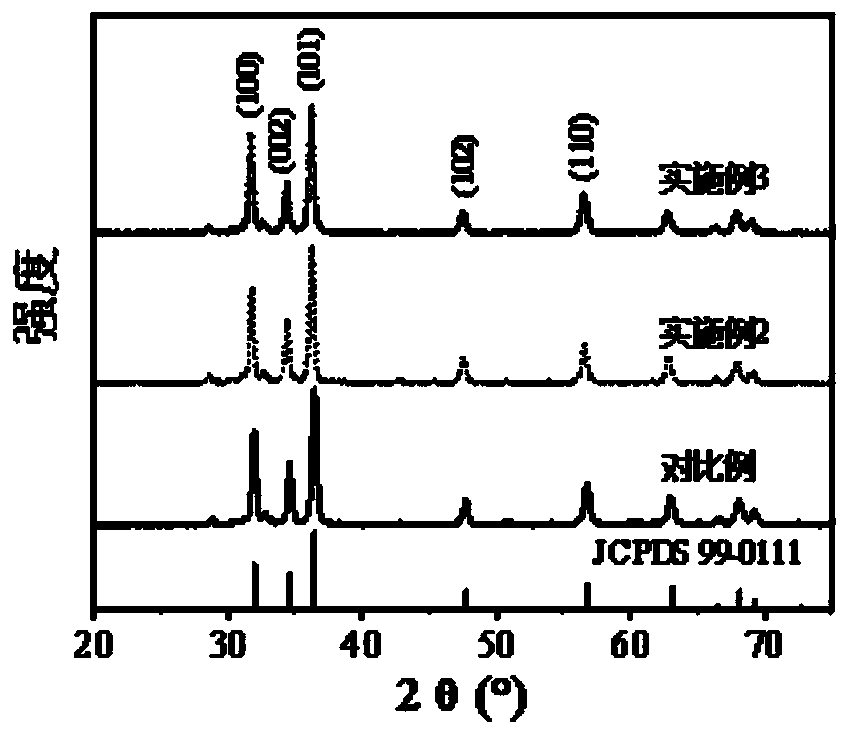

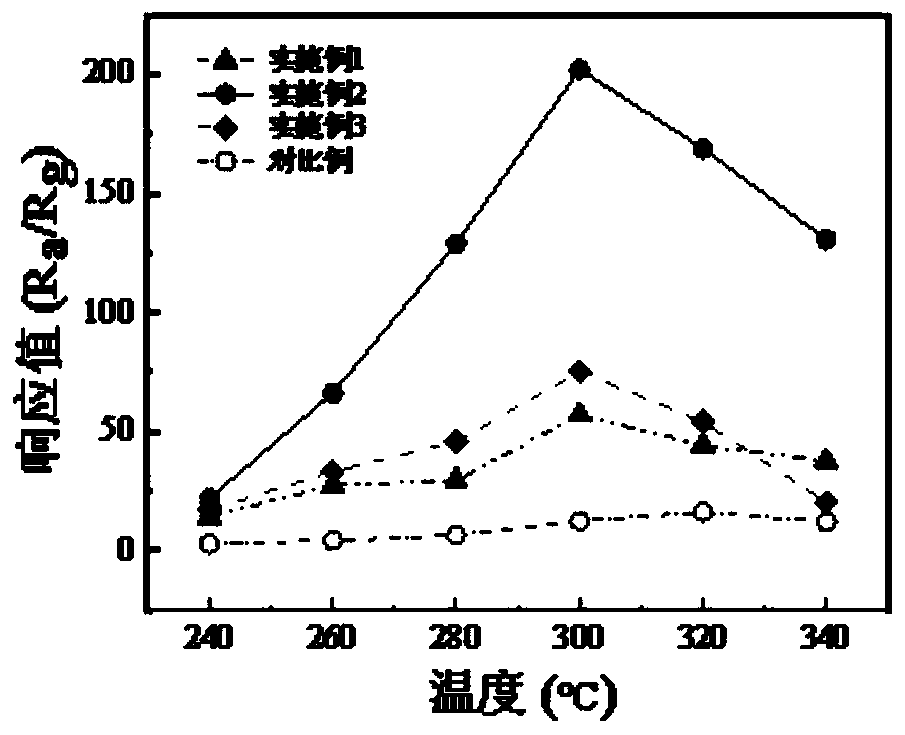

[0066] Weigh 4mmol of zinc nitrate nonahydrate, 4mmol of urea, 0.05g of hexamethylenetetraammonium, add 80mL of deionized water, stir to dissolve for 30 minutes, hydrothermally at 150℃ for 8h, wash and dry in a drying cabinet at 60℃ for 12 hours Obtain precursor materials.

[0067] Weigh 0.01mmol of cobalt nitrate hexahydrate and 0.8mmol of urea, add 80mL of deionized water, stir to dissolve for 15 minutes, add the precursor material, sonicate for 5 minutes to uniformly disperse, continue to stir for 30 minutes, and then hydrothermally react at 120°C Hours, washing, centrifuging, drying at 60°C for 12 hours, and calcining at 450°C for 2 hours to obtain a surface cobalt-doped zinc oxide composite material.

[0068] Put 10 mg of the obtained surface cobalt-doped zinc oxide composite material into a mortar, add 2 mL of ethanol and grind until a completely dispersed sample slurry is obtained, and the slurry is evenly covered on 13.6×7.0mm Ag-Pd alumina by the drip coating method The c...

Embodiment 2

[0071] Weigh 4mmol of zinc nitrate nonahydrate, 4mmol of urea, 0.05g of cetyltrimethylammonium bromide, add 80mL of deionized water, stir and dissolve for 15 minutes, hydrothermally at 120°C for 12h, wash and place in a drying cabinet at 60°C The precursor material was obtained by drying for 12 hours.

[0072] Weigh 0.04mmol of cobalt nitrate hexahydrate and 0.8mmol of urea, add 80mL of deionized water, stir to dissolve for 30 minutes, add the precursor material, sonicate for 5 minutes to uniformly disperse, continue to stir for 30 minutes, and then hydrothermally react at 80°C for 10 Hours, washing, centrifugation, drying at 60°C for 12 hours, and calcination at 350°C for 3 hours to obtain a surface cobalt-doped zinc oxide composite material.

[0073] Put 10 mg of the obtained surface cobalt-doped zinc oxide composite material into a mortar, add 2 mL of ethanol and grind until a completely dispersed sample slurry is obtained, and the slurry is evenly covered on 13.6×7.0mm Ag-Pd al...

Embodiment 3

[0076] Weigh 4mmol of zinc nitrate nonahydrate, 4mmol of urea, and 0.05g of polyvinylpyrrolidone, add 80mL of deionized water, stir and dissolve for 30 minutes, then hydrothermally heat at 140°C for 12 hours, wash and dry in a drying cabinet at 60°C for 12 hours to obtain precursor materials .

[0077] Weigh 0.12mmol of cobalt nitrate hexahydrate and 0.8mmol of urea, add 80mL of deionized water, stir to dissolve for 15 minutes, add the precursor material, sonicate for 5 minutes to uniformly disperse, continue to stir for 30 minutes, and then hydrothermally react at 120℃5 Hours, washing, centrifugation, drying at 60°C for 12 hours, and calcination at 550°C for 2 hours to obtain a surface cobalt-doped zinc oxide composite material.

[0078] Put 10 mg of the obtained surface cobalt-doped zinc oxide composite material into a mortar, add 2 mL of ethanol and grind until a completely dispersed sample slurry is obtained, and the slurry is evenly covered on 13.6×7.0mm Ag-Pd alumina by the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com