Machining method and machining device of cobalt-base superalloy thin-walled sleeve part

A technology of high-temperature alloys and processing methods, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problem of dimensional accuracy not meeting the requirements, and achieve the effect of avoiding deformation and ensuring roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

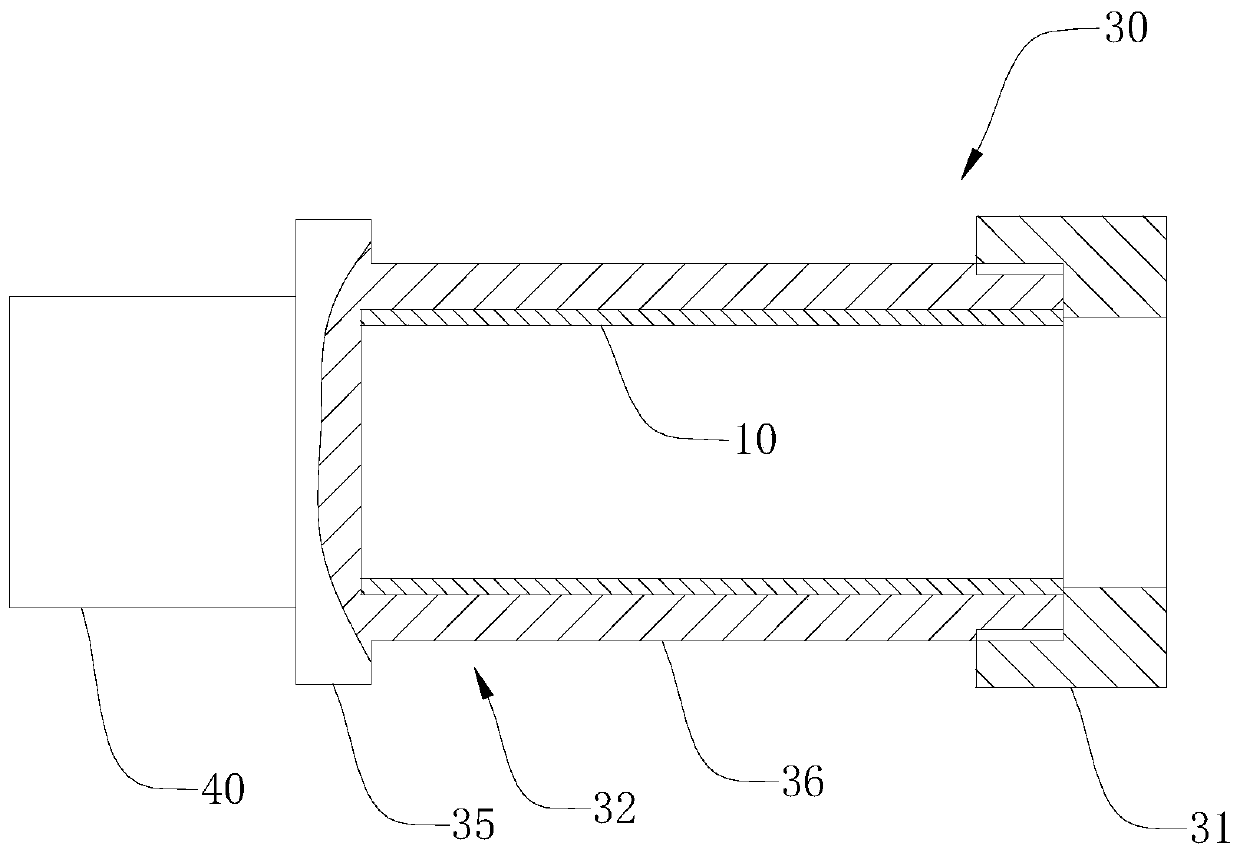

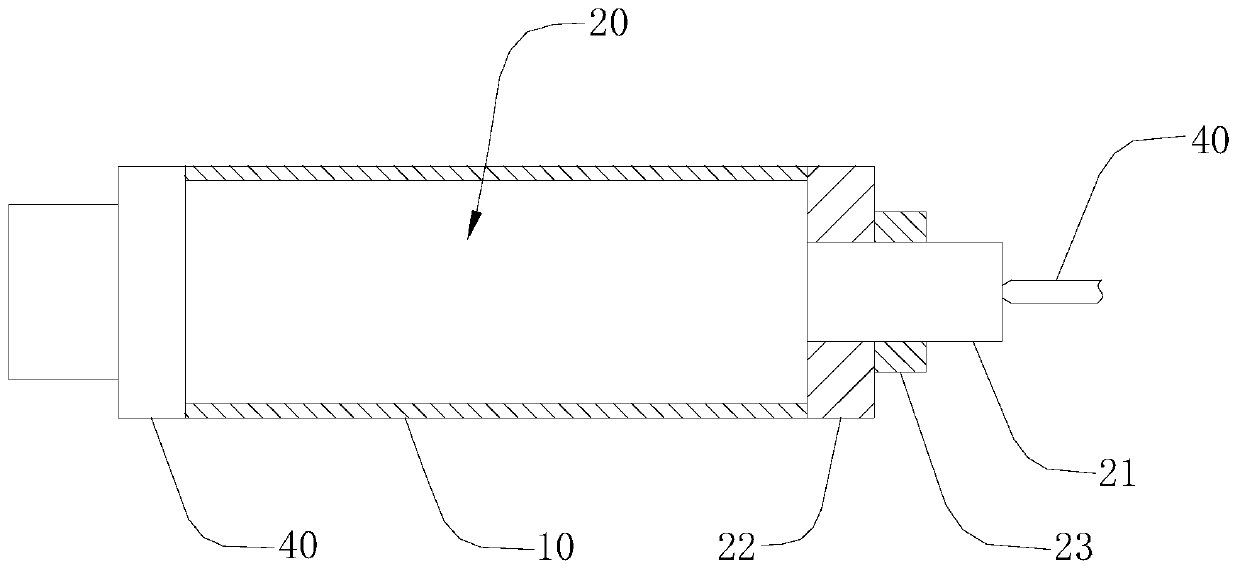

[0050] A processing device for cobalt-based high-temperature alloy thin-walled sleeve parts includes: a clamp assembly 30 for processing the inner circular surface of a workpiece and a mandrel 20 for processing the outer circular surface of the workpiece.

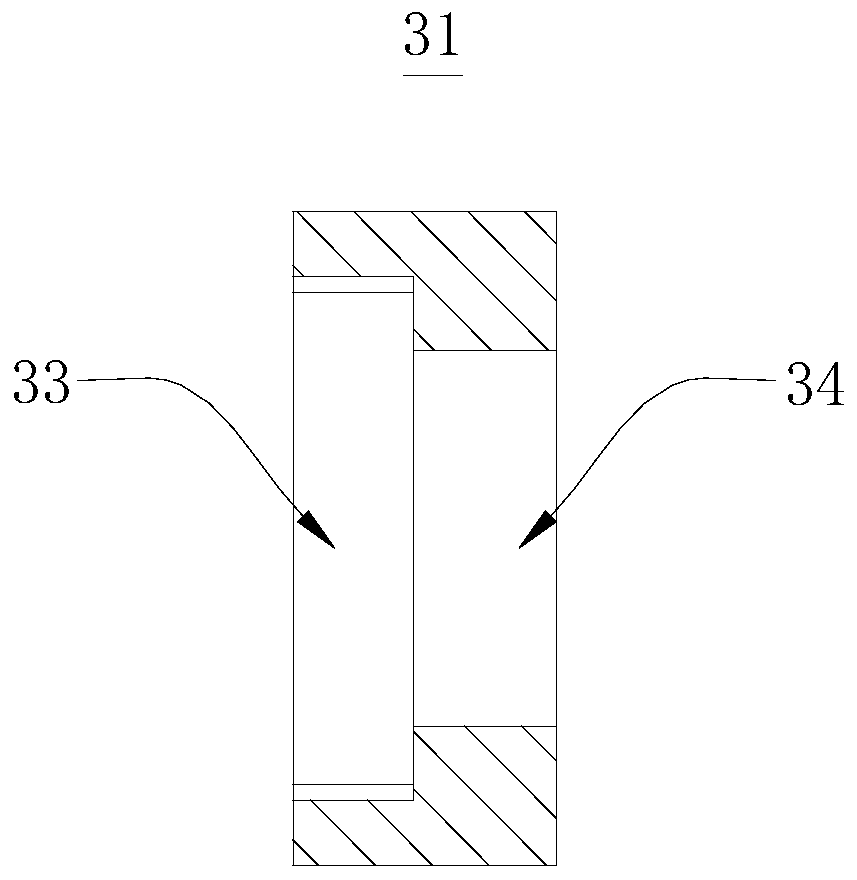

[0051] Please refer to figure 1 and figure 2 , the clip assembly 30 includes a clip 31 and a positioning clip 32 . The middle part of the clamping member 31 is provided with a stepped hole. The stepped hole includes a connection hole 33 and a processing hole 34 whose diameters are successively reduced. The centerlines of the connection hole 33 and the processing hole 34 coincide. The positioning fixture 32 includes a connecting piece 35 and a limiting cylinder 36 . The connecting piece 35 is used to connect to the machine tool 40 to fix the fixture assembly 30 . One end of the limiting cylinder 36 is connected to the connector 35 , the outer wall of the other end is threadedly connected to the sidewall of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com