Tower screw shell processing device

A processing device and conical snail technology, applied in the processing of crustaceans, shrimp/lobster processing, solid separation, etc., can solve the problems of difficult cleaning, troublesome picking, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

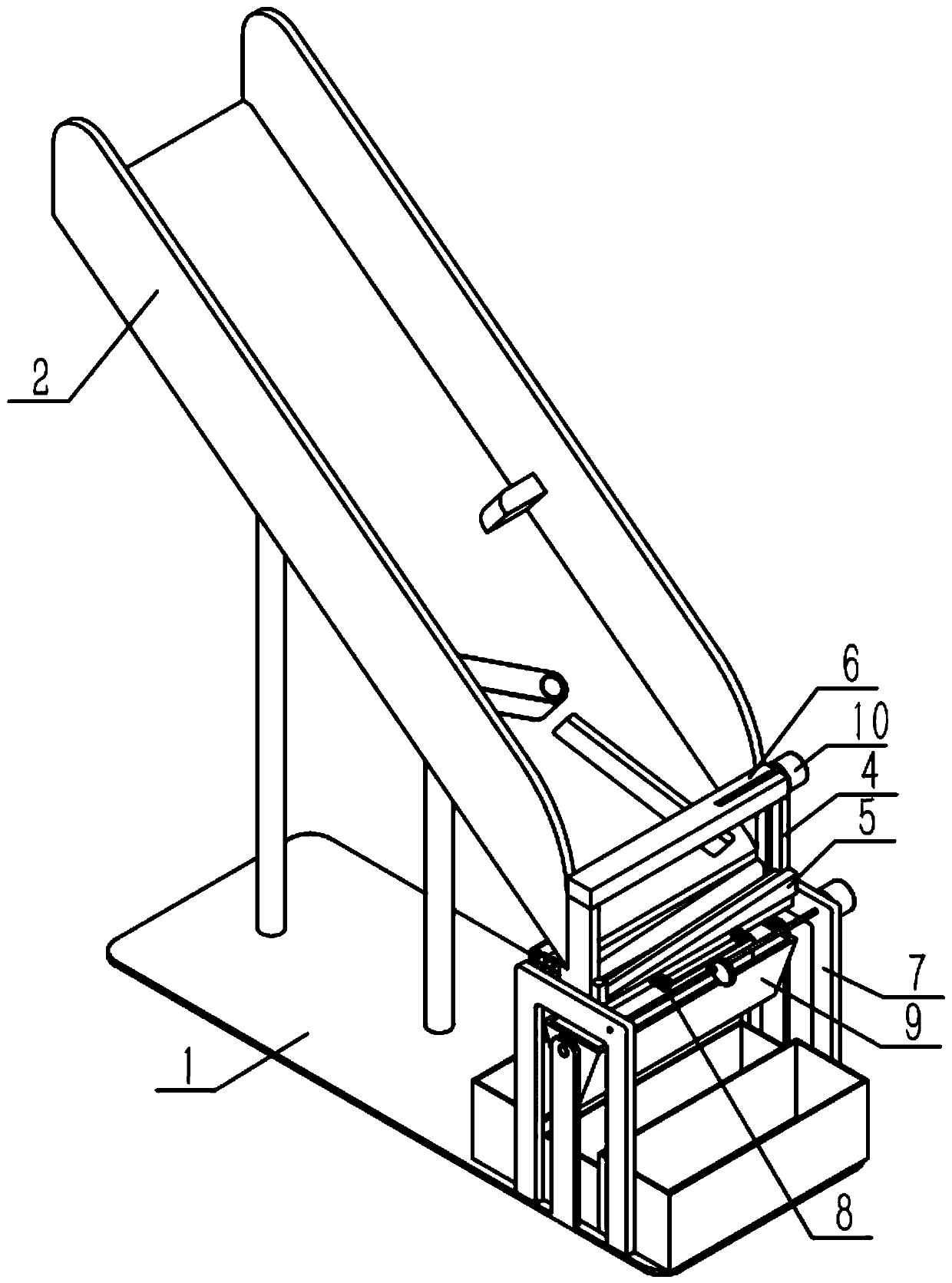

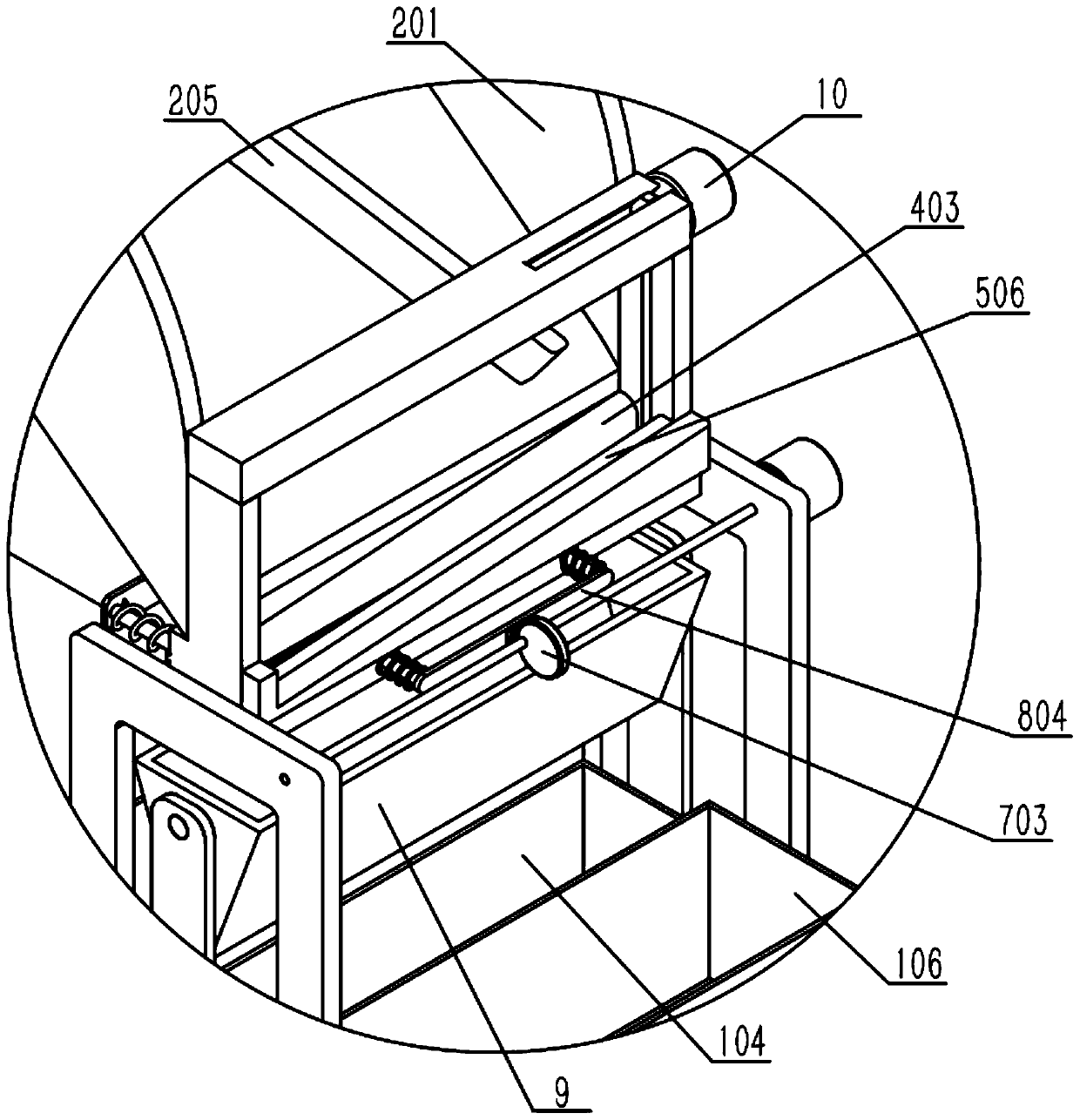

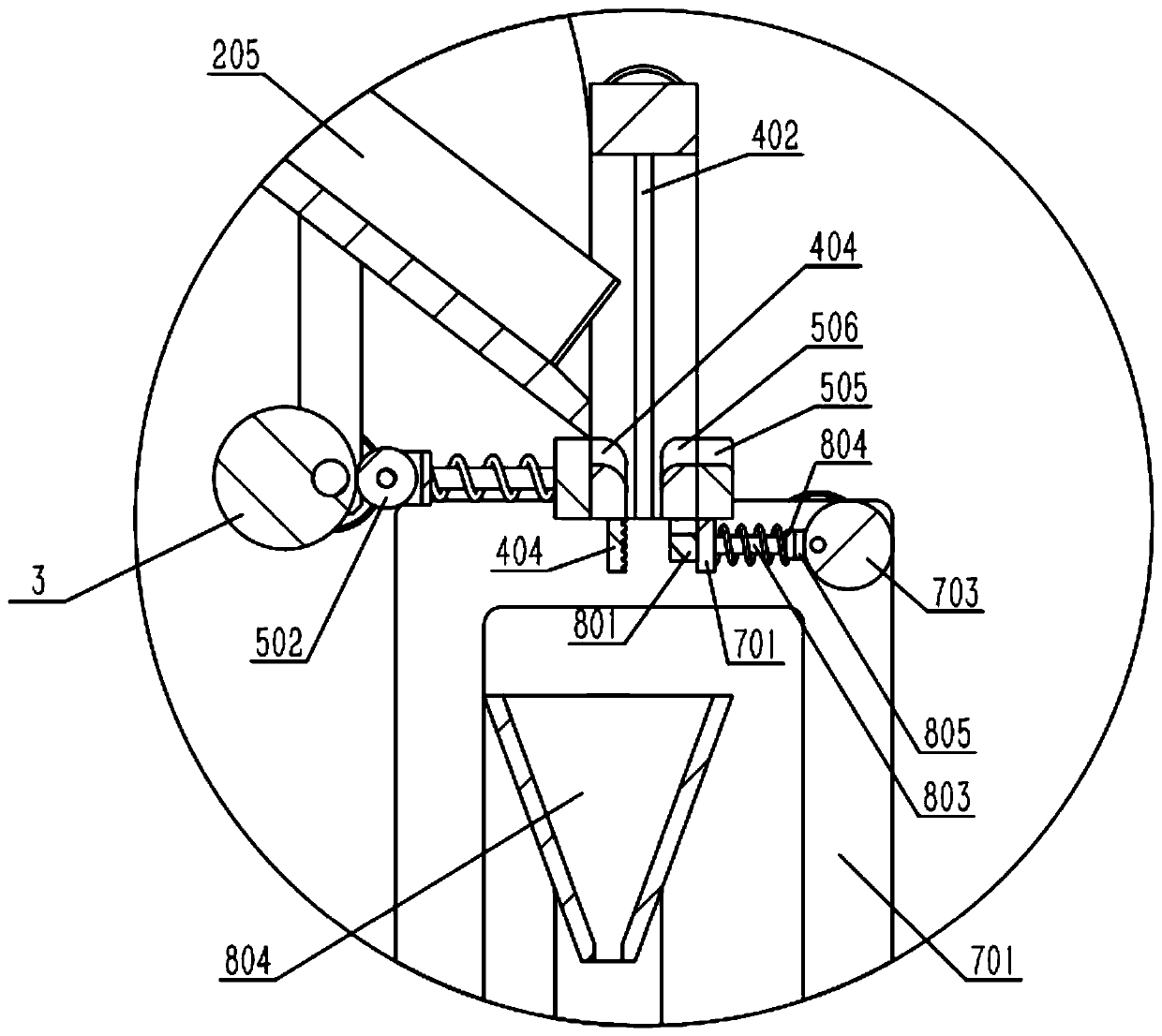

[0033] Such as Figure 1-12 As shown, a cone screw processing device includes a base body 1, a guideway 2, a trigger part 3 for unloading, a fixed side 4, a movable side 5, a top side 6, a crushing frame 7, a crushing part 8, and a screening bucket 9 and motor III10, the left side of the base body 1 is fixedly connected to the guideway 2, the unloading trigger part 3 is connected to the right side of the guideway 2, the fixed side 4 is fixedly connected to the lower right end of the guideway 2, and the movable side 5 is connected to the The right side of the fixed side 4 is in contact with the trigger part 3, the top side 6 is affixed to the upper end of the fixed side 4, the crushing frame 7 is affixed to the right side of the base body 1, and the crushing part 8 is in the middle of the upper end of the crushing frame 7 Connected, the crushing frame 7 is in contact with the crushing part 8, the screening bucket 9 is rotatably connected to the upper end on the right side of th...

specific Embodiment approach 2

[0035] Such as Figure 1-12 As shown, the base body 1 includes a base body 101, a mounting column 102, a stand 103, a scrap box 104, a processing box 105 and a rework box 106, and two mounting columns 102 are affixed to the left side of the base body 101, and the base body The right side of 1 is affixed to the processing box 105, the scrap box 104 and the rework box 106 sequentially from left to right. The rework box 106 stores the conical screw with the head facing right and the tail facing left accidentally when it slides down. The conical screw falling in this way will fall on the fixed inclined card part 403 or the movable inclined card part 506, and it needs to be manually transferred to the rework box 106 Inside.

specific Embodiment approach 3

[0037] Such as Figure 1-12As shown, the guideway 2 includes a guideway body 201, a preset block 202, a servo motor 203, an anti-jamming lever 204 and a precision guide plate 205, and the middle part of the front side of the guideway body 201 is fixedly connected with the preset block 202. , the servo motor 203 is fixedly connected to the lower end of the guideway body 201, the output shaft of the servomotor 203 is rotationally connected with the guideway body 201, the right end of the anti-card lever 204 is fixedly connected with the output shaft of the servomotor 203, and the anti-card lever 204 The left end of the guideway body 201 can be attached to the rear end surface, the rotation center of the anti-jamming lever 204 is located in the middle of the guideway body 201, the anti-jamming lever 204 is located on the right side of the preset block 202, and the precision guide plate 205 is tilted and fixed. Connected to the guideway body 201 , the left end of the guideway body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com