Cooling fin stamping and riveting structure

A technology of heat dissipation fins and riveting structure, which is applied to heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of unstable combination of heat dissipation fins, easy bending and heat dissipation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

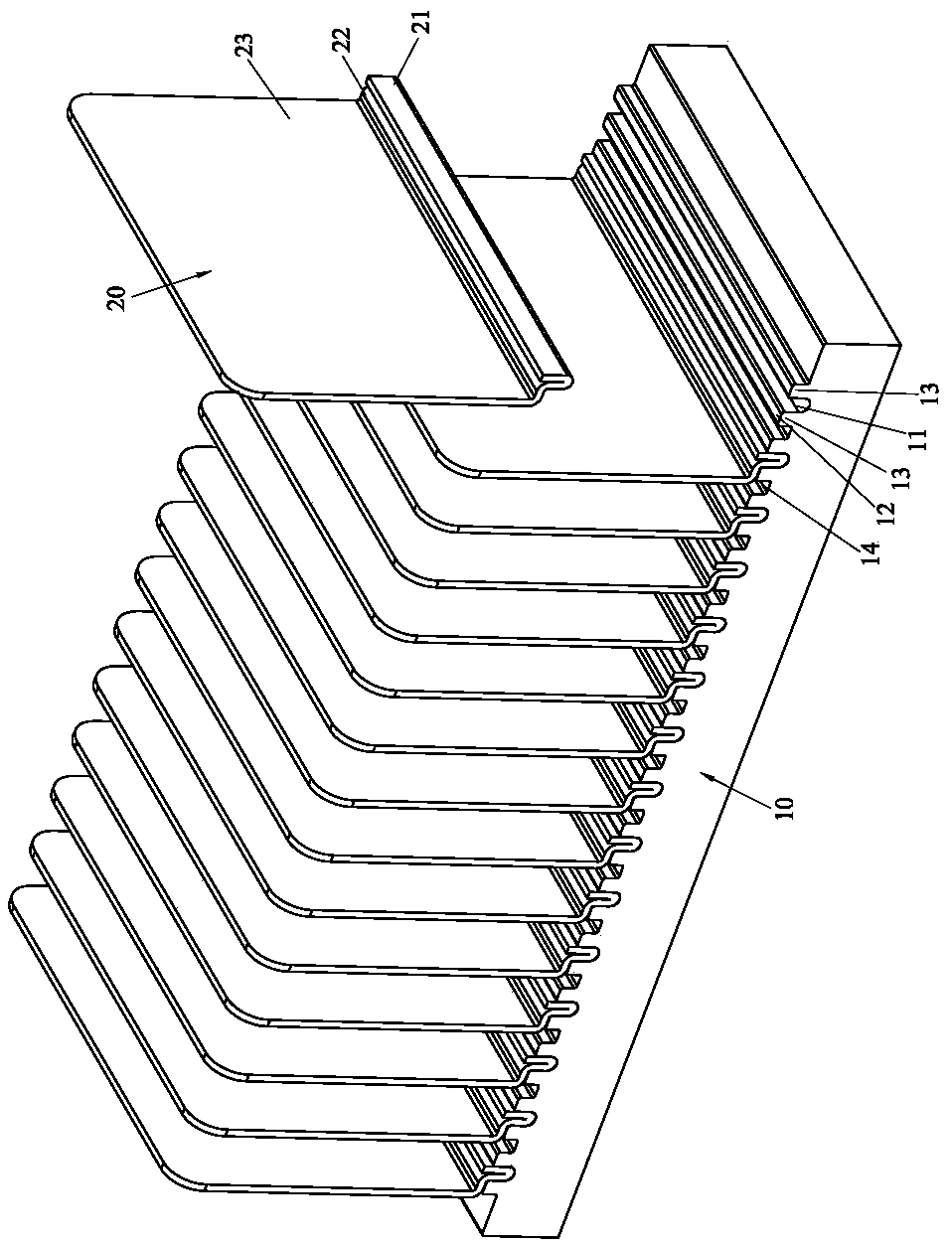

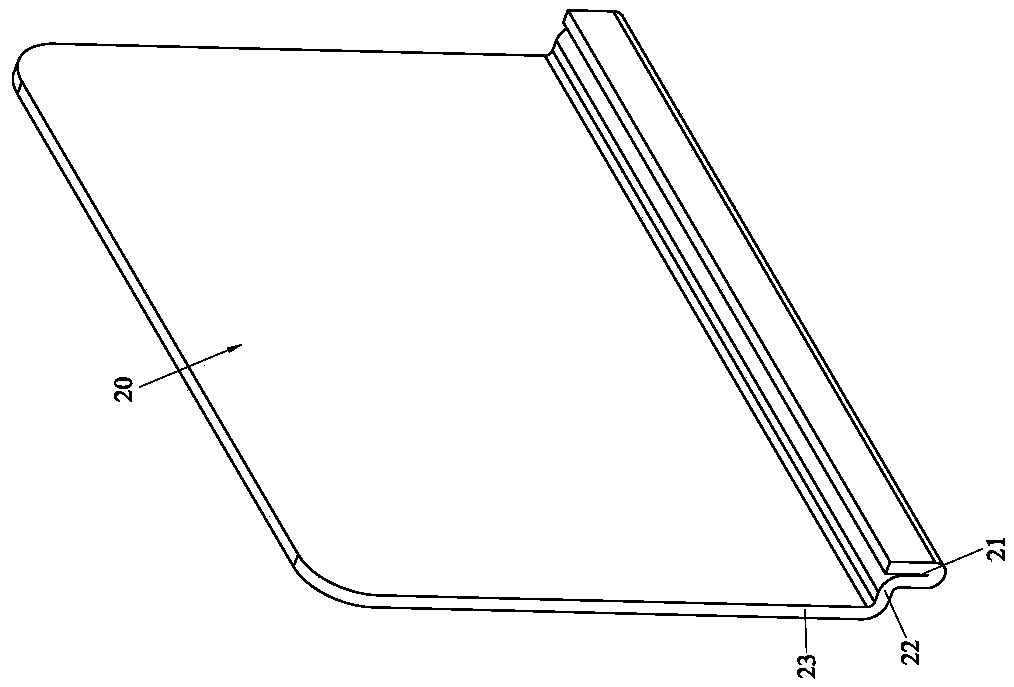

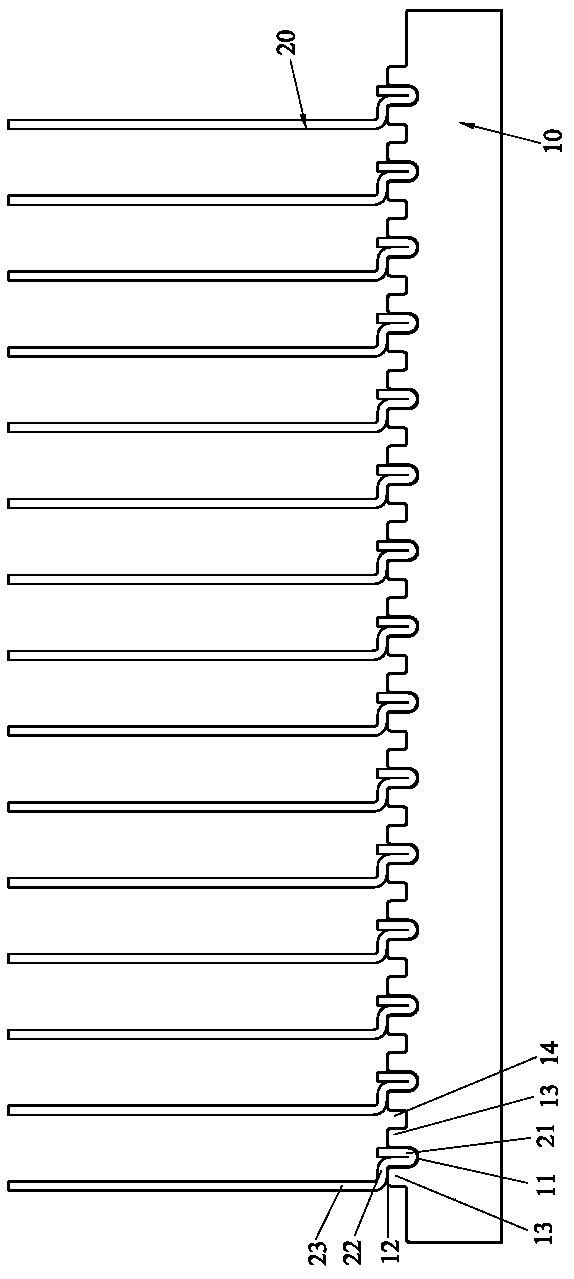

[0045] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including the base 10 and the cooling fins 20 .

[0046] The surface of the base 10 is provided with a groove 11 for inserting the cooling fins 20. At least one side of the opening of the groove 11 has a contact surface 12; in this embodiment, the base 10 is a copper, aluminum, copper Base alloy or aluminum base alloy base, both sides of the groove 11 are formed with a strip-shaped boss 13, the contact surface 12 is located on the top surface of one of the strip-shaped bosses 13, and the contact surface 12 is The horizontal plane, but not limited to the horizontal plane, can also be an inclined plane; and, the grooves 11 are arranged in parallel at intervals, and between two adjacent grooves 11 are recessed grooves 14 formed on the surface of the base 10 , to increase the heat dissipation area and improve the ventilation and heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com