An agricultural seed drying device with rotary stirring

A technology of rotary stirring and drying equipment, which is applied in the agricultural field, can solve the problems of low drying efficiency and inability to dry, and achieve the effects of increasing storage time, increasing temperature, and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

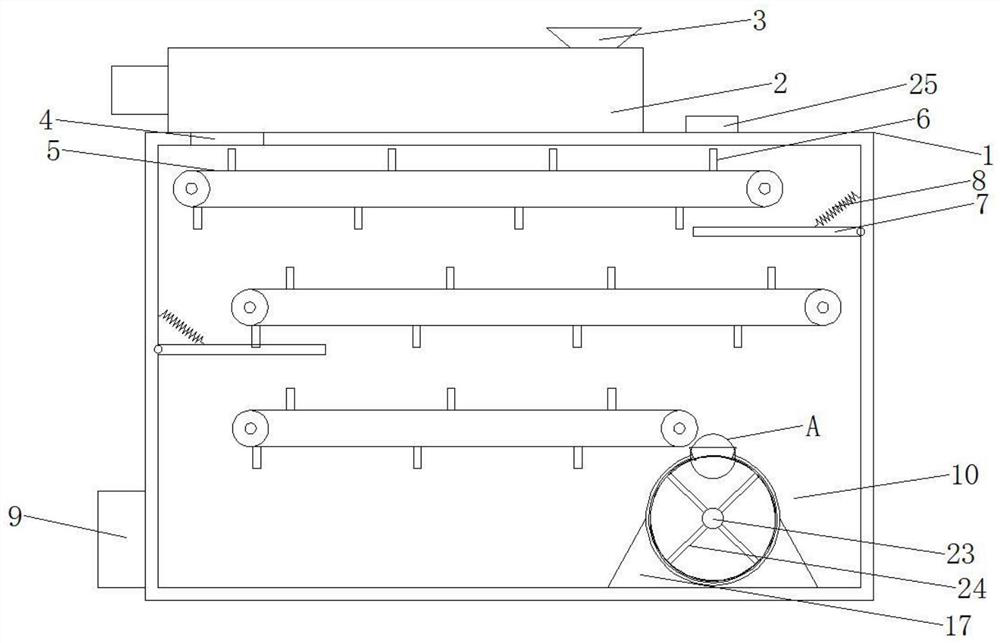

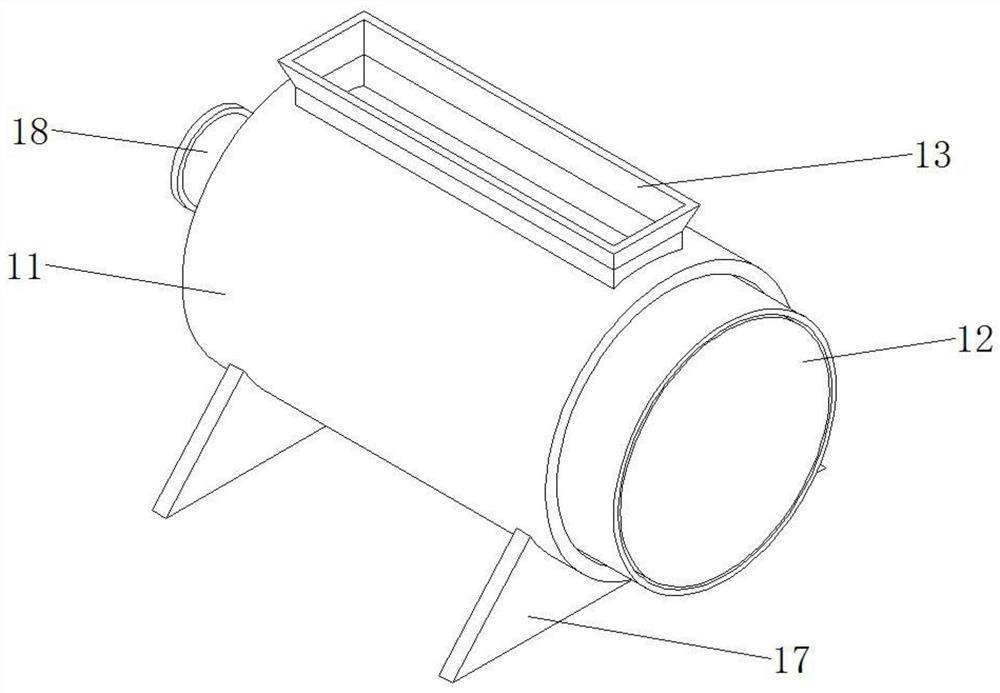

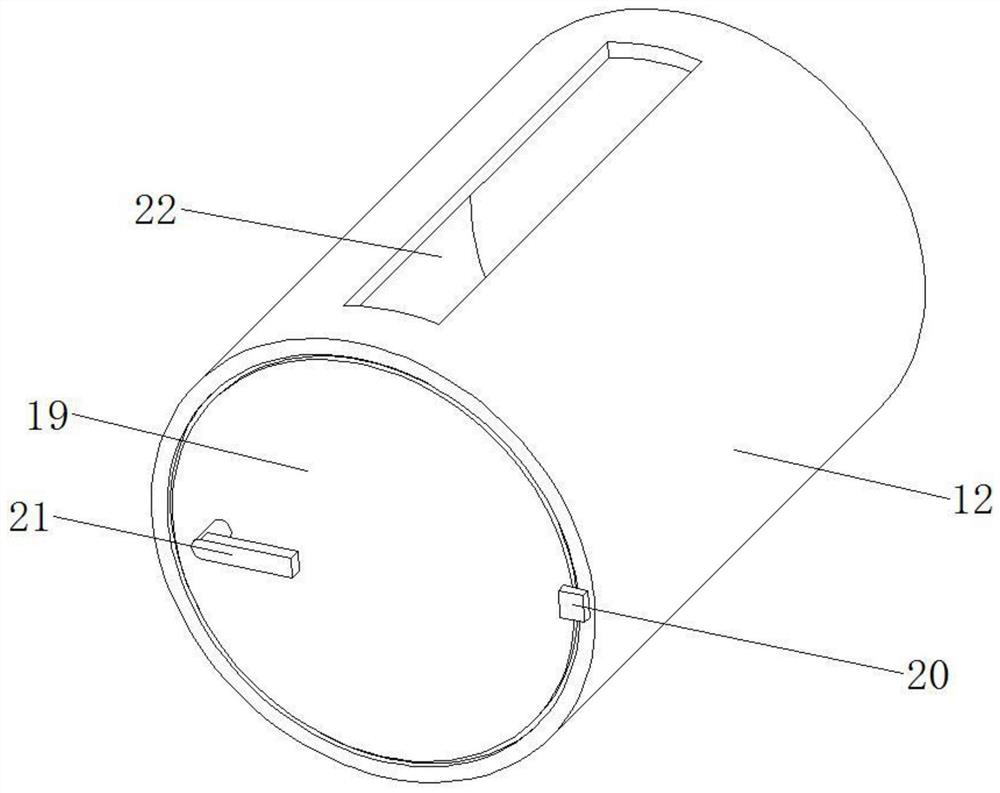

[0022] Please refer to the figure, in the embodiment of the present invention, an agricultural seed drying device with rotary stirring includes a housing 1, a feeding heating cylinder 2, a feeding hopper 3, a feeding port 4 and a conveyor belt 5; The feed heating cylinder 2 is horizontally and fixedly installed on the top of the housing 1, and the right end of the feed heating cylinder 2 is connected to the feed hopper 3, and the seeds are filled into the feed heating cylinder 2, and the feed heating cylinder 2 is provided with a screw The auger is driven by a motor to rotate, and the seeds are transported to the left. A heating layer is provided in the feeding heating cylinder 2 to heat the inside, so that the seeds are heated while being transported in the feeding heating cylinder 2, and the temperature of the seeds is increased. The bottom left end of the feeding heating cylinder 2 communicates with the inside of the casing 1 through the feeding port 4, and the heated seeds ...

Embodiment 2

[0026]On the basis of Embodiment 1, an elastic material guide plate 7 is arranged between two adjacent conveyor belts 5 up and down, and the elastic material guide plate 7 is connected to the side wall of the housing 1 through a pin shaft rotation. The upper surface of the upper surface is fixedly connected with a spring 8, and the other end of the spring 8 is fixed on the side wall of the housing 1, and the elastic material guide plate 7 is pulled by the spring 8 to keep it in a horizontal position, and the elastic material guide plate 7 is located on the upper conveyor belt 5 The falling seeds fall on the elastic material guide plate 7, which increases the weight of the elastic material guide plate 7, thereby making it inclined, sending the seeds on it down, and slowing down the falling speed of the seeds. In order to improve its air permeability In addition, several holes are provided on the elastic material guide plate 7 to increase the contact with the air; on the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com