Method for treating wastewater from comprehensive disposal center for hazardous waste

A technology of hazardous waste and treatment method, applied in the environmental field, can solve the problems of difficult to stably meet the treatment standard, poor anti-shock load capacity, poor removal effect, etc., and achieves that equipment and structures occupy less land, high reliability, and stability. High standard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

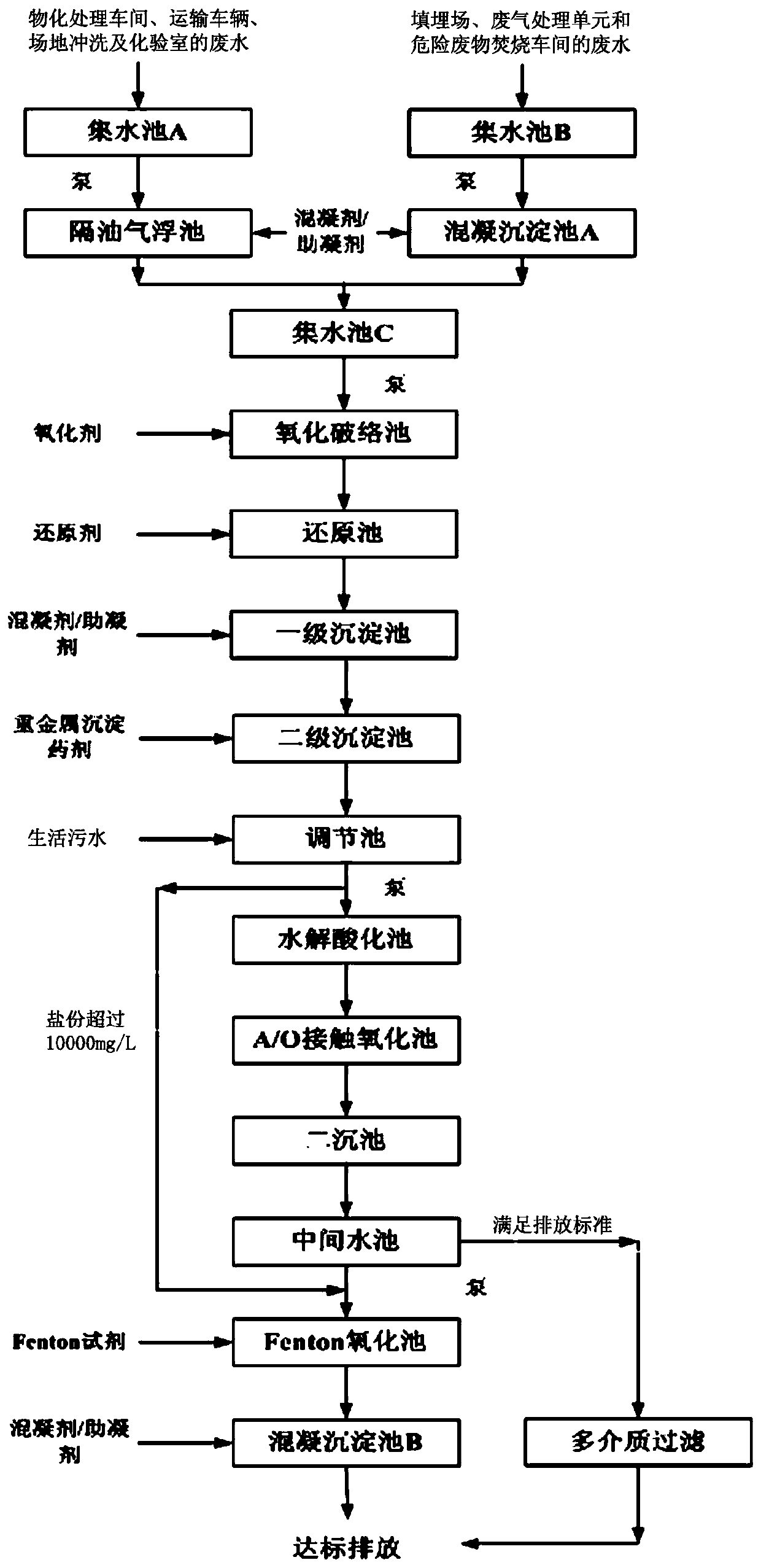

[0035] A method for treating waste water in a hazardous waste comprehensive disposal center, comprising the following steps:

[0036] 1) Classified collection and quality-based treatment: Separately collect waste water from physical and chemical treatment workshops, transport vehicles, site washing and laboratories for pretreatment with oil separation and air flotation; collect waste water from landfills, waste gas treatment units and hazardous waste incineration workshops The wastewater is collected separately and pretreated by coagulation and sedimentation; the coagulant is basic aluminum chloride (PAC), the coagulant aid is polyacrylamide (PAM), and the dosage is PAC: 40~50mg / L, respectively. PAM: 5~10mg / L;

[0037] 2) Mix the effluent from step 1) and adjust the pH value to 6~8, then add the oxidant and stir evenly; the oxidant is hydrogen peroxide (H 2 o 2 ), the dosage is: 0.8~1mL / L;

[0038] 3) Adjust the pH of the effluent from step 2) to 2~3, then add the reducing ...

Embodiment 2

[0050] A method for treating waste water in a hazardous waste comprehensive disposal center, comprising the following steps:

[0051] 1) Classified collection and quality-based treatment: Separately collect waste water from physical and chemical treatment workshops, transport vehicles, site washing and laboratories for pretreatment with oil separation and air flotation; collect waste water from landfills, waste gas treatment units and hazardous waste incineration workshops The wastewater is collected separately and pretreated by coagulation and sedimentation; the coagulant is basic aluminum chloride (PAC), the coagulant aid is polyacrylamide (PAM), and the dosage is PAC: 30~40mg / L, PAM: 1~5mg / L;

[0052] 2) Mix the effluent from step 1) and adjust the pH value to 6~8, then add the oxidant and stir evenly; the oxidant is hydrogen peroxide (H 2 o 2 ), the dosage is: 0.5~0.8mL / L;

[0053] 3) Adjust the pH of the effluent from step 2) to 2~3, then add the reducing agent and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com