Production technology of anti-wicking building membrane

A kind of architectural membrane material and production process technology, which is applied in the production process field of anti-wicking architectural membrane materials, can solve the problems of poor anti-wicking effect, etc., and achieve the effects of prolonging the service life, reducing production costs, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

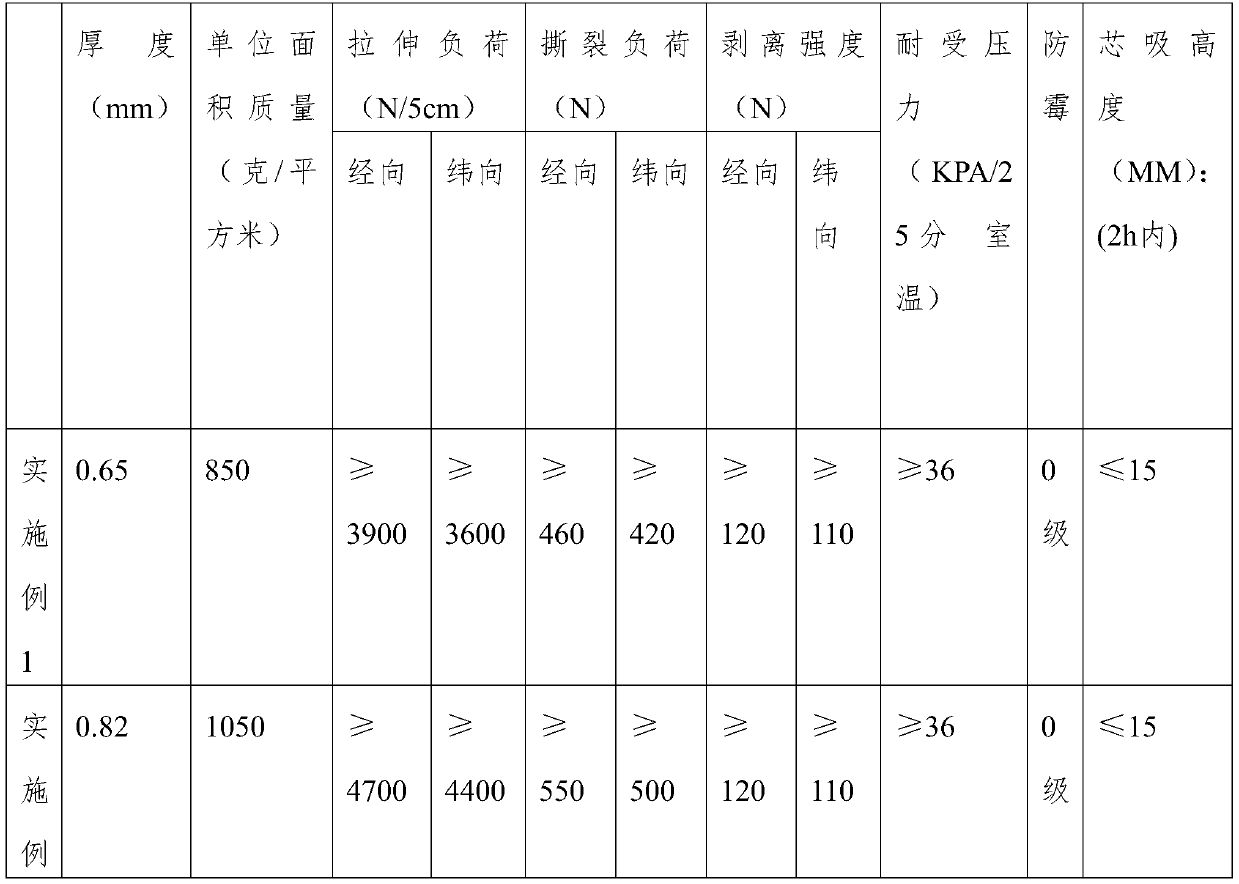

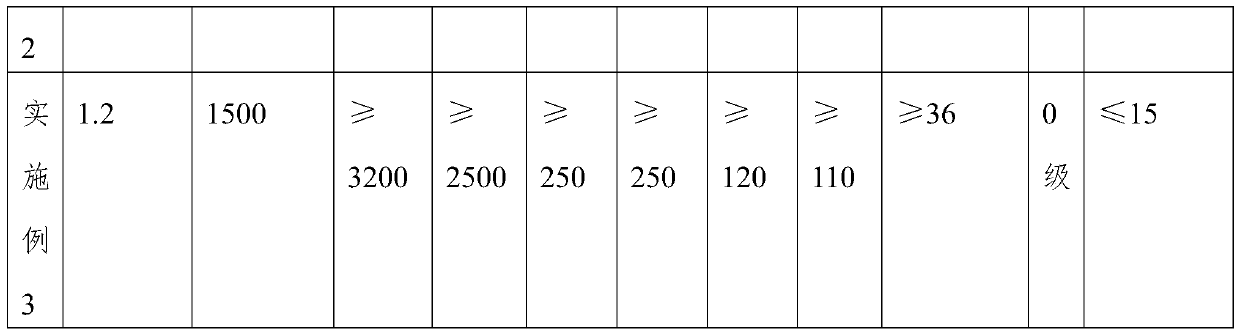

Embodiment 1

[0042] The specific steps of a production process of an anti-wicking architectural membrane are as follows:

[0043] (1) Preparation of base cloth

[0044] The polyester yarn is woven into a base cloth by a double warp and double weft weaving method; the base cloth is twisted in the weft direction during the preparation process. The structural parameters of the base fabric are: yarn thickness: 1000D in the warp direction, 1000D in the weft direction; fabric density: 30 threads / inch in the warp direction, and 30 threads / inch in the weft direction. The grammage of the base cloth is 263 grams per square meter.

[0045] (2) Preparation of pvc slurry

[0046] The formula of the pvc slurry is as follows (parts by weight): 95 parts of pvc paste resin, 60 parts of epoxy soybean oil, 2.5 parts of barium zinc stabilizer, 7 parts of flame retardant, 0.3 part of anti-ultraviolet agent, 9 parts of nanometer calcium, 0.3 part of mildew-proof and antibacterial agent.

[0047] (3) The pen...

Embodiment 2

[0055] The specific steps of a production process of an anti-wicking architectural membrane are as follows:

[0056] (1) Preparation of base cloth

[0057] The polyester yarn is woven into a base cloth by a double warp and double weft weaving method; the base cloth is twisted in the weft direction during the preparation process. The structural parameters of the base fabric are: yarn thickness: 1300D in the warp direction, 1300D in the weft direction; fabric density: 30 threads / inch in the warp direction, and 30 threads / inch in the weft direction. The grammage of the base cloth is 345 grams per square meter.

[0058] (2) Preparation of pvc slurry

[0059] The formula of the pvc slurry is as follows (parts by weight): 105 parts of pvc paste resin, 65 parts of epoxy soybean oil, 3 parts of barium zinc stabilizer, 9 parts of fire retardant, 0.5 part of anti-ultraviolet agent, 11 parts of nanometer calcium, 0.5 part of anti-mildew and antibacterial agent.

[0060] (3) The penet...

Embodiment 3

[0068] The specific steps of a production process of an anti-wicking architectural membrane are as follows:

[0069] (1) Preparation of base cloth

[0070] The polyester yarn is woven into a base cloth by a double warp and double weft weaving method; the base cloth is twisted in the weft direction during the preparation process. The structural parameters of the base fabric are: yarn thickness: 1500D in the warp direction, 1500D in the weft direction; fabric density: 30 threads / inch in the warp direction, and 34 threads / inch in the weft direction. The grammage of the base cloth is 421 grams per square meter.

[0071] (2) Preparation of pvc slurry

[0072] The formula of described pvc slurry is as follows (parts by weight): 100 parts of pvc paste resin, 62.5 parts of epoxy soybean oil, 2.75 parts of barium zinc stabilizer, 8 parts of fire retardant, 0.4 part of anti-ultraviolet agent, 10 parts of nanometer calcium, 0.4 parts of anti-mold and antibacterial agent.

[0073] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com