Acid solution preparation and injection device for lead storage battery

A lead-acid battery and injection device technology, used in lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve problems such as terminal corrosion, battery heating, deviation and displacement, and achieve the effect of ensuring acid addition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

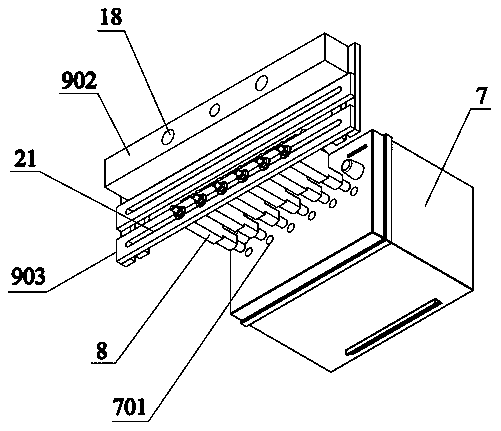

[0030] A kind of acid preparation and injection device for lead storage battery, such as figure 1 As shown, it includes a frame 1, and the frame 1 is provided with a water tank 2, a conveyor belt 3 and a guard plate 4 sequentially from front to back, and two sets of acid preparation mechanisms 5 are arranged symmetrically on both sides of the water tank 2. Two sets of acid liquid injection mechanisms 6 are correspondingly arranged above the conveyor belt 3, and a first motor 14 is provided on the conveyor belt 3 to drive its operation;

[0031] Such as figure 2 and image 3As shown, the acid liquid injection mechanism 6 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com