Binocular-vision-positioning-technology-based method for measuring dynamic axis position of revolution body

A binocular vision positioning and measurement method technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems affecting the measurement accuracy of the total station and the accuracy of laser ranging, and achieve fast measurement speed and high positioning accuracy , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

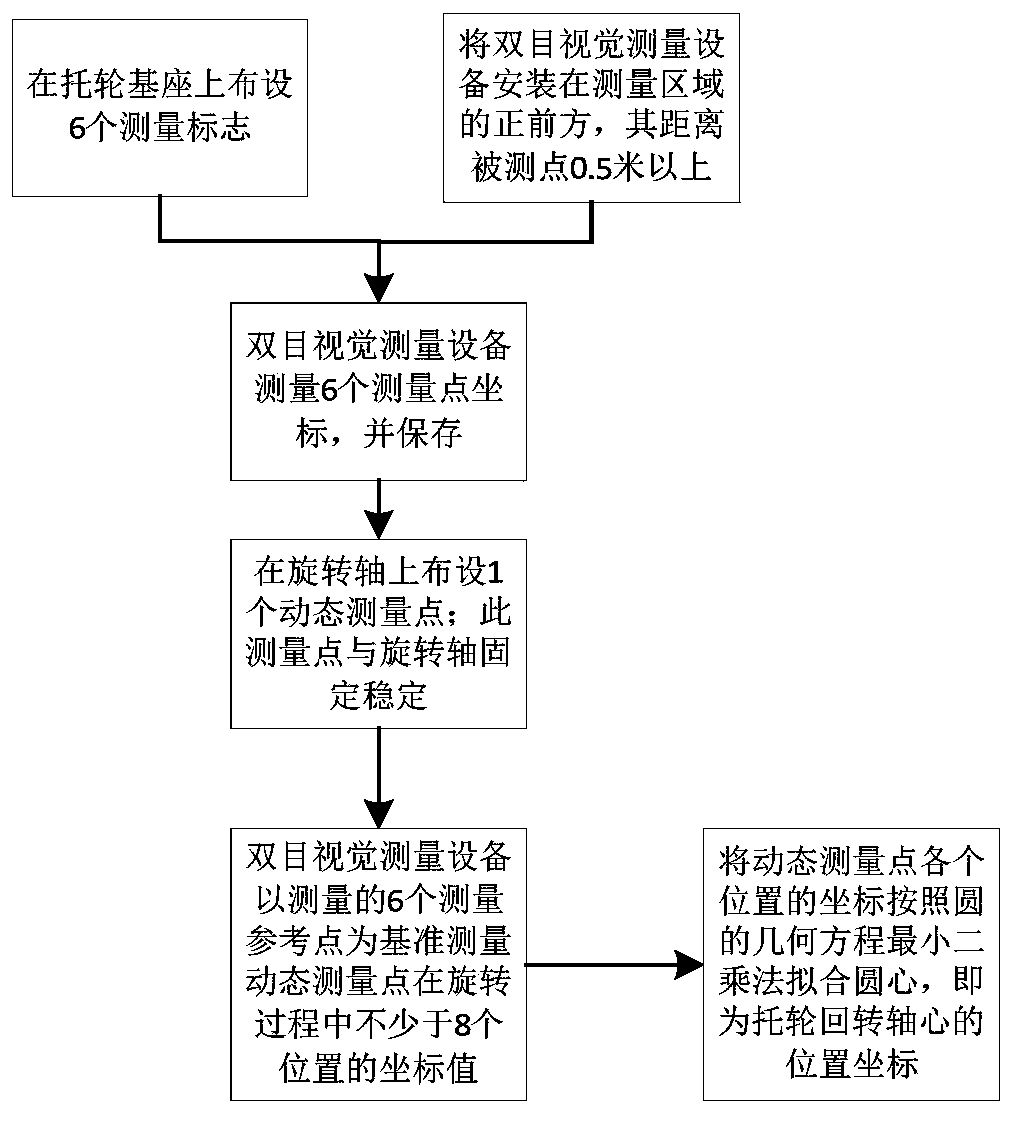

[0031] like figure 1 and Image 6 As shown, in this embodiment, the rotary body is selected as the supporting wheel of the rotary kiln, and the axis of the rotary body is located on the rotating shaft 1. The method for measuring the dynamic axis position of the rotary body based on the binocular vision positioning technology of the present invention includes the following steps:

[0032] step 1:

[0033] Arrange more than 6 measurement reference points A on the rotating shaft base 2, which are stable reference points for dynamic measurement, and need to be arranged at stable positions adjacent to the dynamic monitoring points. During the rotation of the rotating shaft 1, the measuring reference points A are relatively The rotating shaft base 2 should be stable.

[0034] Fix the binocular vision positioning device 3 in front of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com