Separation and purification method of ruthenium in irradiation uranium target

A separation, purification and irradiation technology is applied in the field of separation and purification of ruthenium in irradiated uranium targets, which can solve the problems of inability to take into account the decontamination effect and the need for mass spectrometry measurement, and achieves good decontamination effect, high recovery rate and reasonable conditions. Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for separating and purifying ruthenium in an irradiated uranium target adopts an oxidation extraction-reduction stripping method, and the steps are as follows:

[0021] (1) Dissolve the irradiated uranium target with hot nitric acid, and after the solution is cooled, extract twice with 30% TBP kerosene to separate and remove uranium and plutonium;

[0022] (2) Evaporate the raffinate to dryness, dissolve the obtained substance in sulfuric acid with a concentration of 0.6mol / L, add Ce(SO 4 ) 2 The sulfuric acid with a concentration of 0.6mol / L oxidizes ruthenium to RuO 4 ;

[0023] (3) Add carbon tetrachloride to extract RuO 4 ;

[0024] (4) Take the organic phase and wash it twice with sulfuric acid with a concentration of 0.6mol / L;

[0025] (5) Using ascorbic acid aqueous solution with a concentration of 0.03 mol / L as the aqueous reverse extraction of ruthenium to obtain a ruthenium reverse extraction solution.

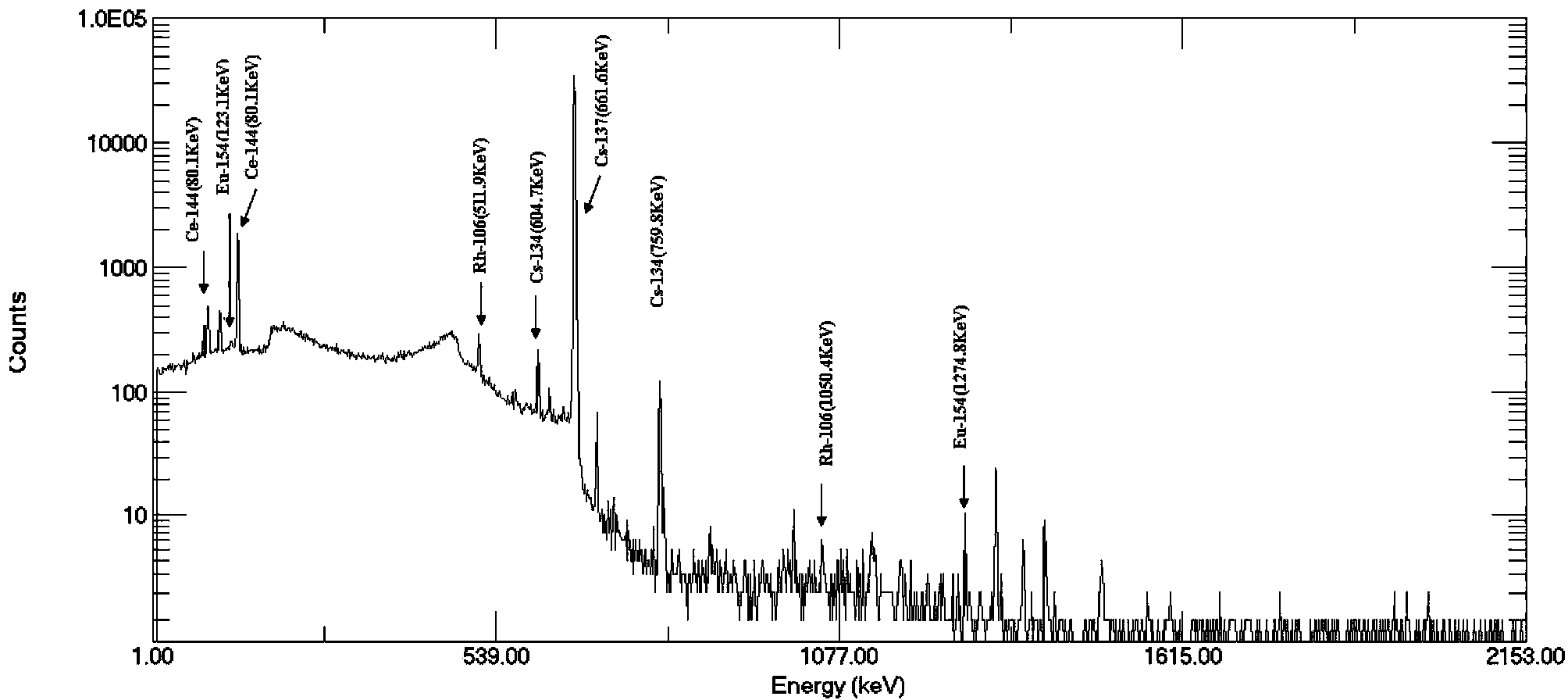

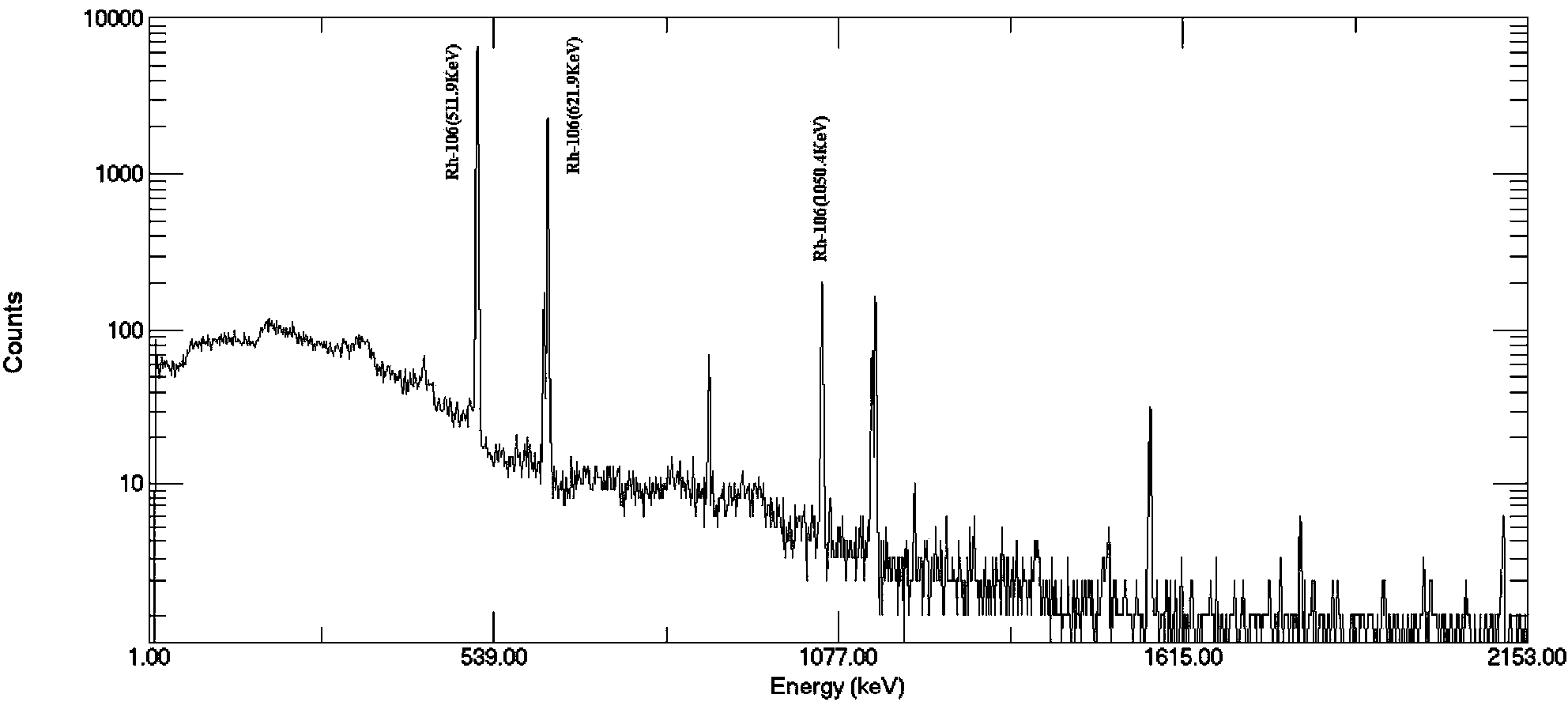

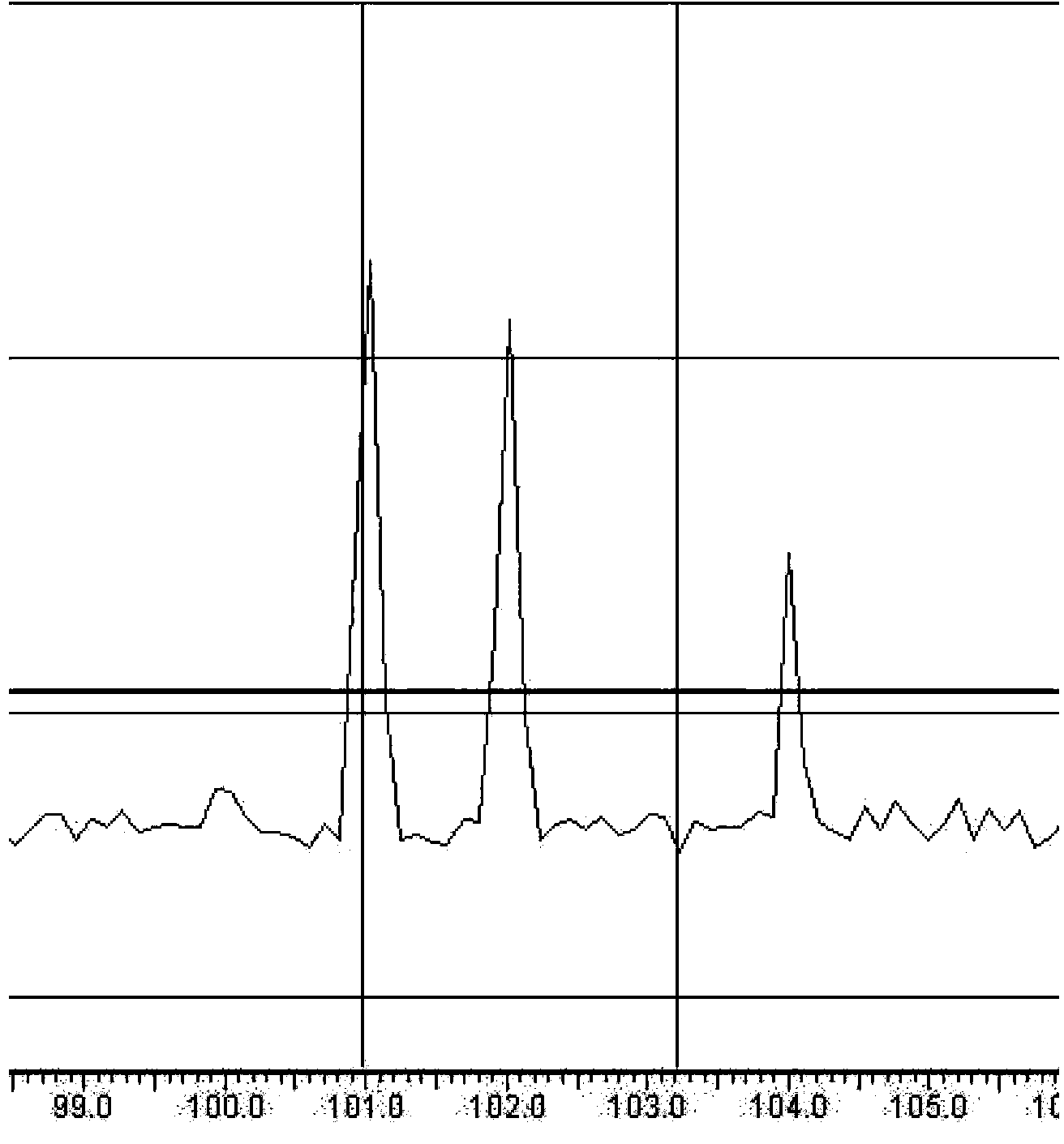

[0026] The test results of Example 1 are ...

Embodiment 2

[0033] A method for separating and purifying ruthenium in an irradiated uranium target adopts an oxidation extraction reduction stripping method, and the steps are as follows:

[0034] (1) Dissolve the irradiated uranium target with hot nitric acid, and after the solution is cooled, extract twice with 30% TBP-kerosene to separate and remove uranium and plutonium;

[0035] (2) Evaporate the raffinate to dryness, dissolve the obtained substance with sulfuric acid with a concentration of 0.4mol / L, add Ce(SO 4 ) 2 The sulfuric acid with a concentration of 0.4mol / L oxidizes ruthenium to RuO 4 ;

[0036] (3) Add carbon tetrachloride to extract RuO 4 ;

[0037] (4) Take the organic phase and wash it twice with sulfuric acid with a concentration of 0.4mol / L;

[0038] (5) Using ascorbic acid aqueous solution with a concentration of 0.01 mol / L as the aqueous reverse extraction of ruthenium to obtain a ruthenium reverse extraction solution.

Embodiment 3

[0040] A method for separating and purifying ruthenium in an irradiated uranium target adopts an oxidation extraction-reduction stripping method, and the steps are as follows:

[0041] (1) Dissolve the irradiated uranium target with hot nitric acid, and after the solution is cooled, extract twice with 30% TBP-kerosene to separate and remove uranium and plutonium;

[0042] (2) Evaporate the raffinate to dryness, dissolve the obtained substance with sulfuric acid with a concentration of 0.8mol / L, add Ce(SO 4 ) 2 The sulfuric acid with a concentration of 0.8mol / L oxidizes ruthenium to RuO 4 ;

[0043] (3) Add carbon tetrachloride to extract RuO 4 ;

[0044] (4) Take the organic phase and wash it twice with sulfuric acid with a concentration of 0.8mol / L;

[0045] (5) Using ascorbic acid aqueous solution with a concentration of 0.08 mol / L as the aqueous reverse extraction of ruthenium to obtain a ruthenium reverse extraction solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com