A device for automatic detection of runout of bevel gears in automobiles

An automatic detection, bevel gear technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problem of low accuracy of manual detection of gear teeth, and achieve the effect of low detection accuracy and high creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

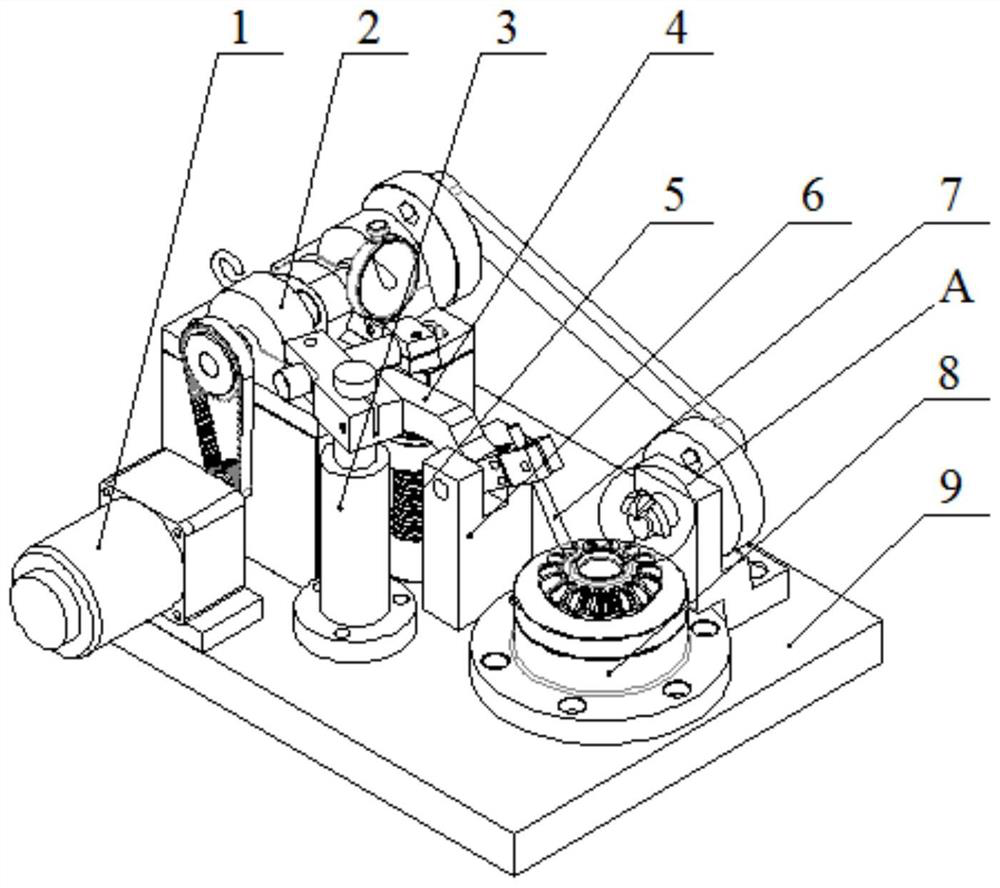

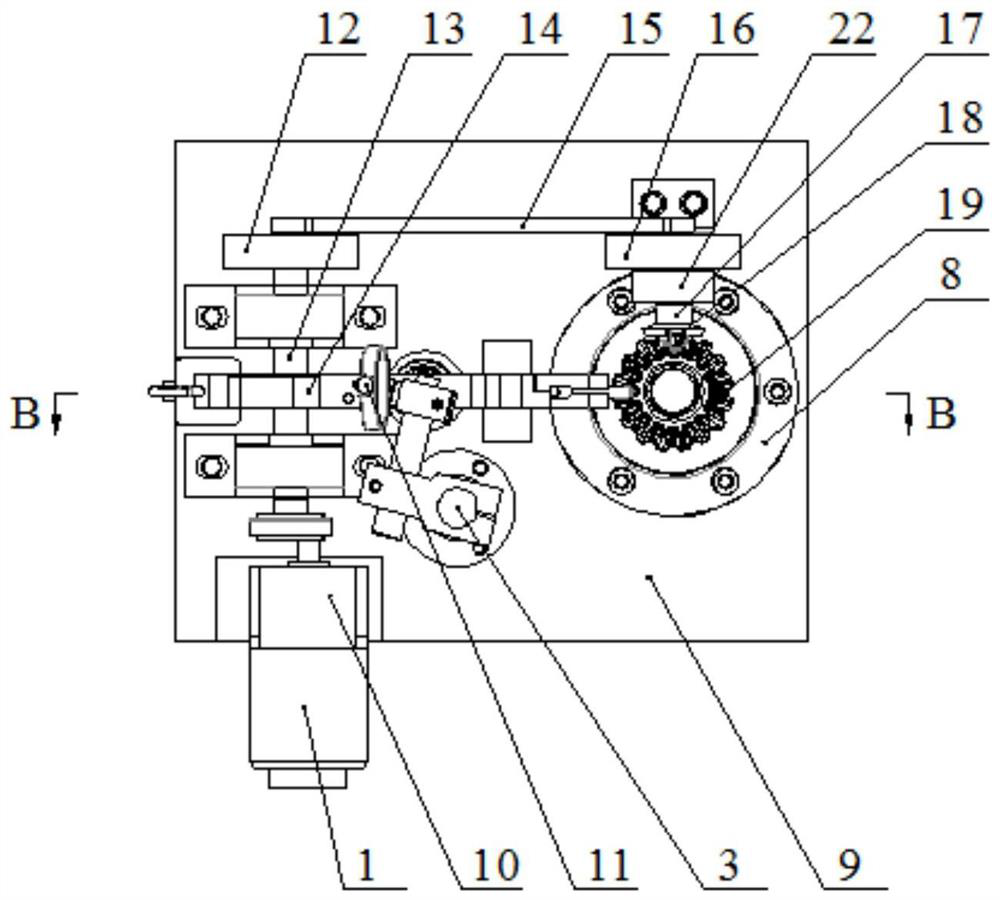

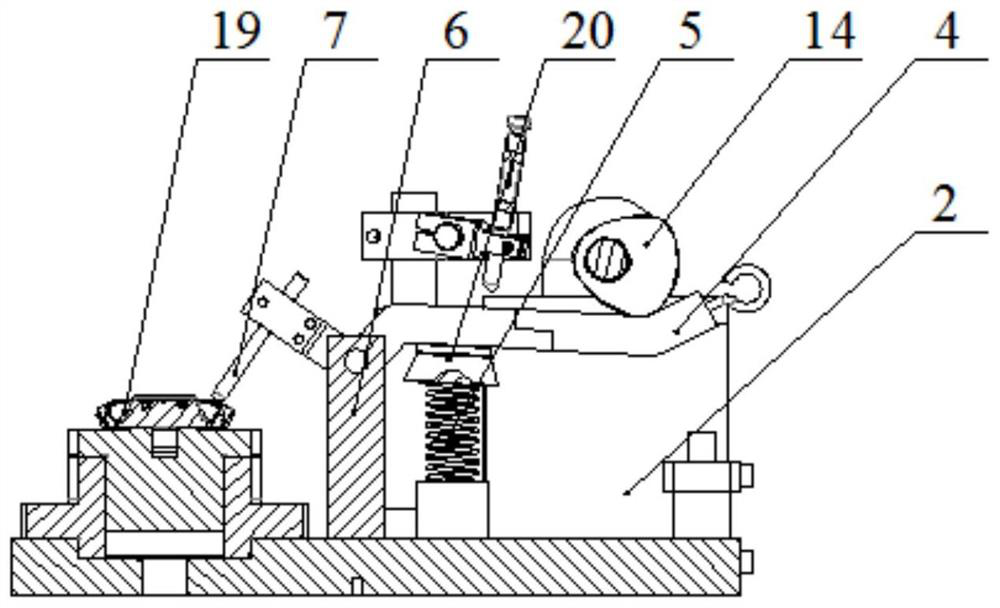

[0029] An automatic bevel gear detection device for automobiles, comprising a base 9, and a shaft bracket 2, a curved rod bracket 6, and a gear bracket 8 fixed in turn on the base; an eccentric wheel 14 is installed in the shaft bracket, and the top of the curved rod bracket rotates A curved rod 4 is installed, one end of the curved rod is slidingly matched with the outer circumference of the eccentric wheel, and the other end of the curved rod is fixedly equipped with a detection rod 7; one side of the shaft bracket is connected with a power unit that provides rotational power for the eccentric wheel, and the shaft bracket The other si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com