Compound type ribbed one-side thermal insulation block

A side insulation and composite technology, applied to building materials, building components, walls, etc., can solve the problems of large differences in thermal expansion coefficients of materials, affecting the insulation effect of insulation systems, and different degrees of cold and heat shrinkage, so as to ensure the bearing capacity , reduce the overall weight, reduce the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

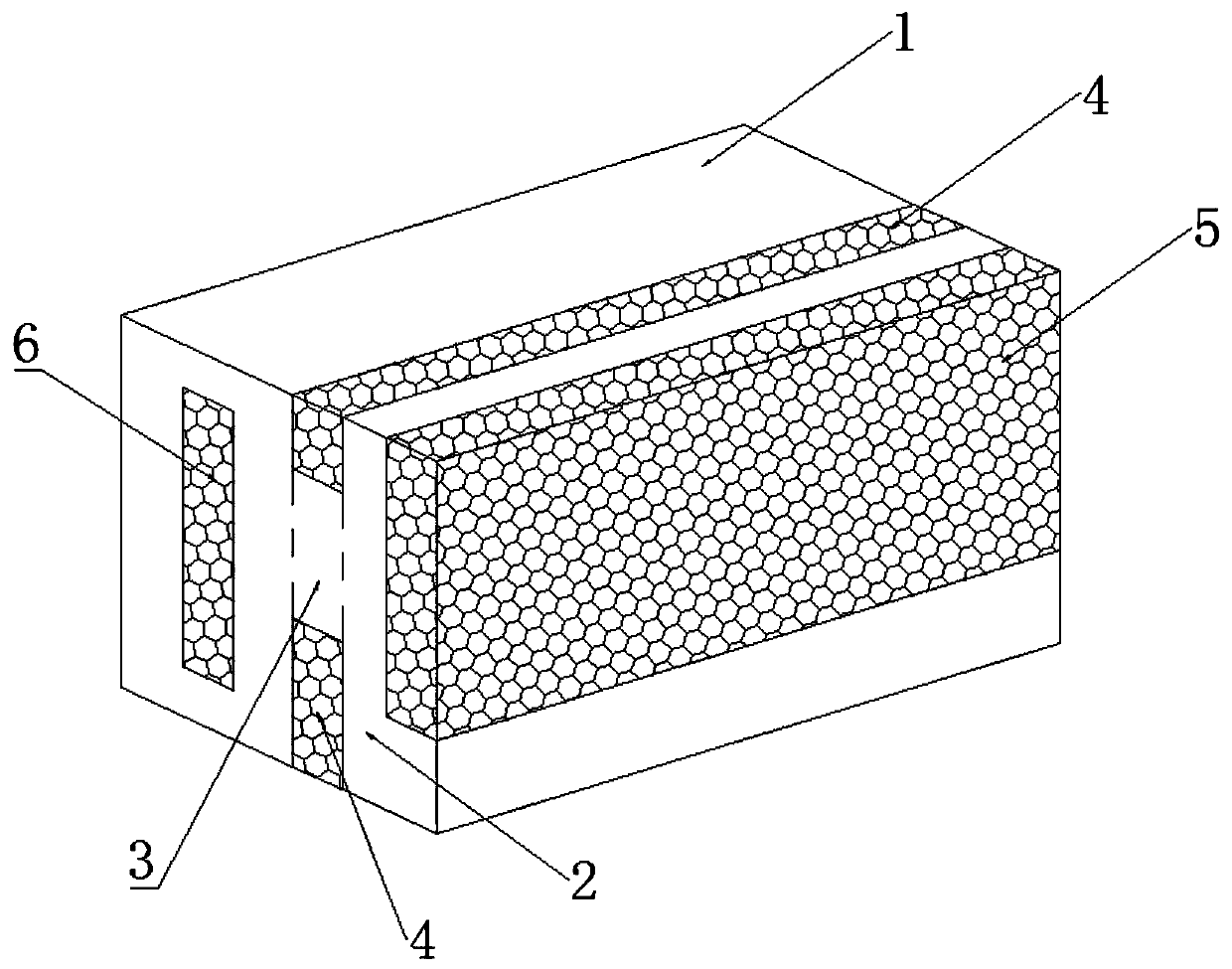

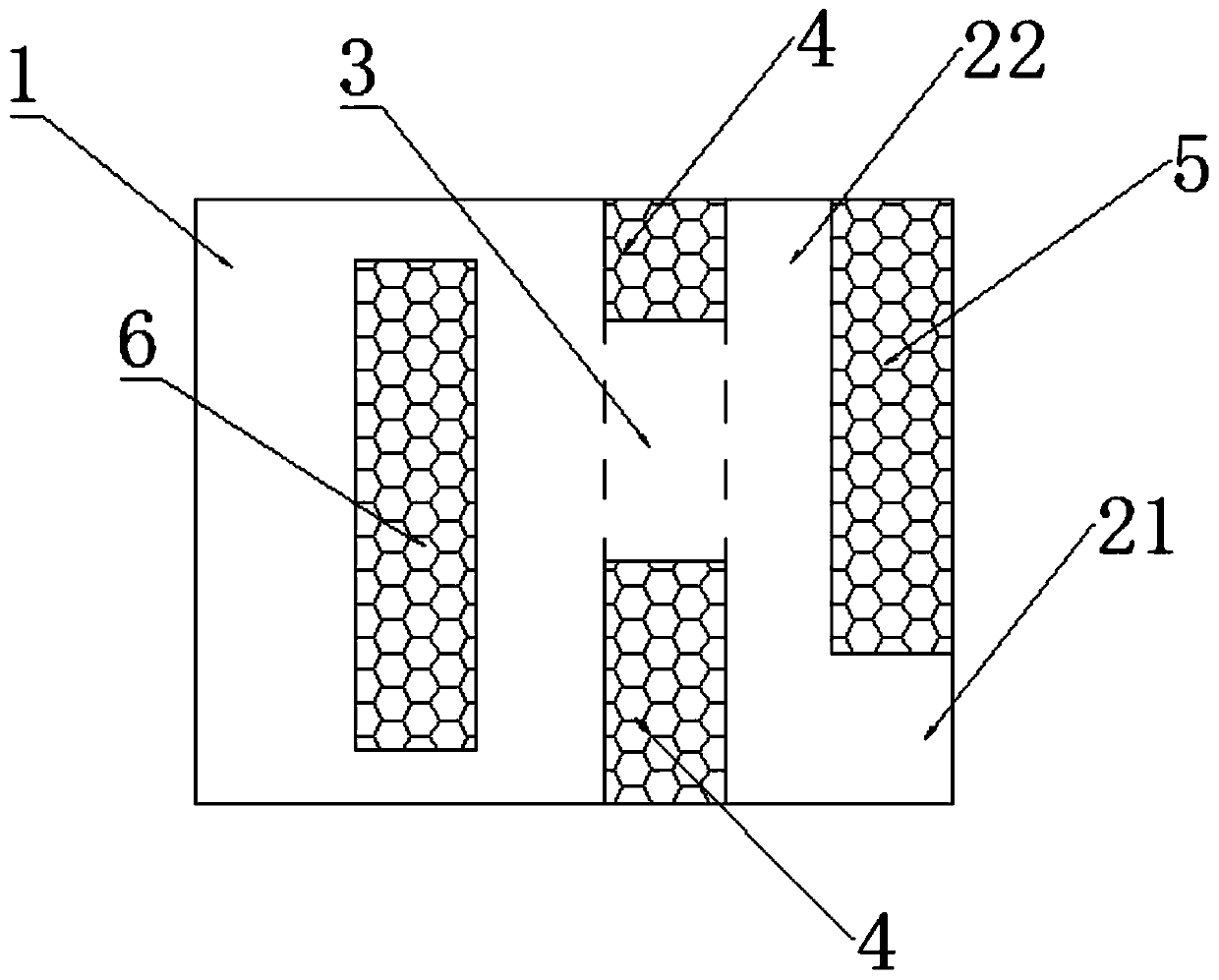

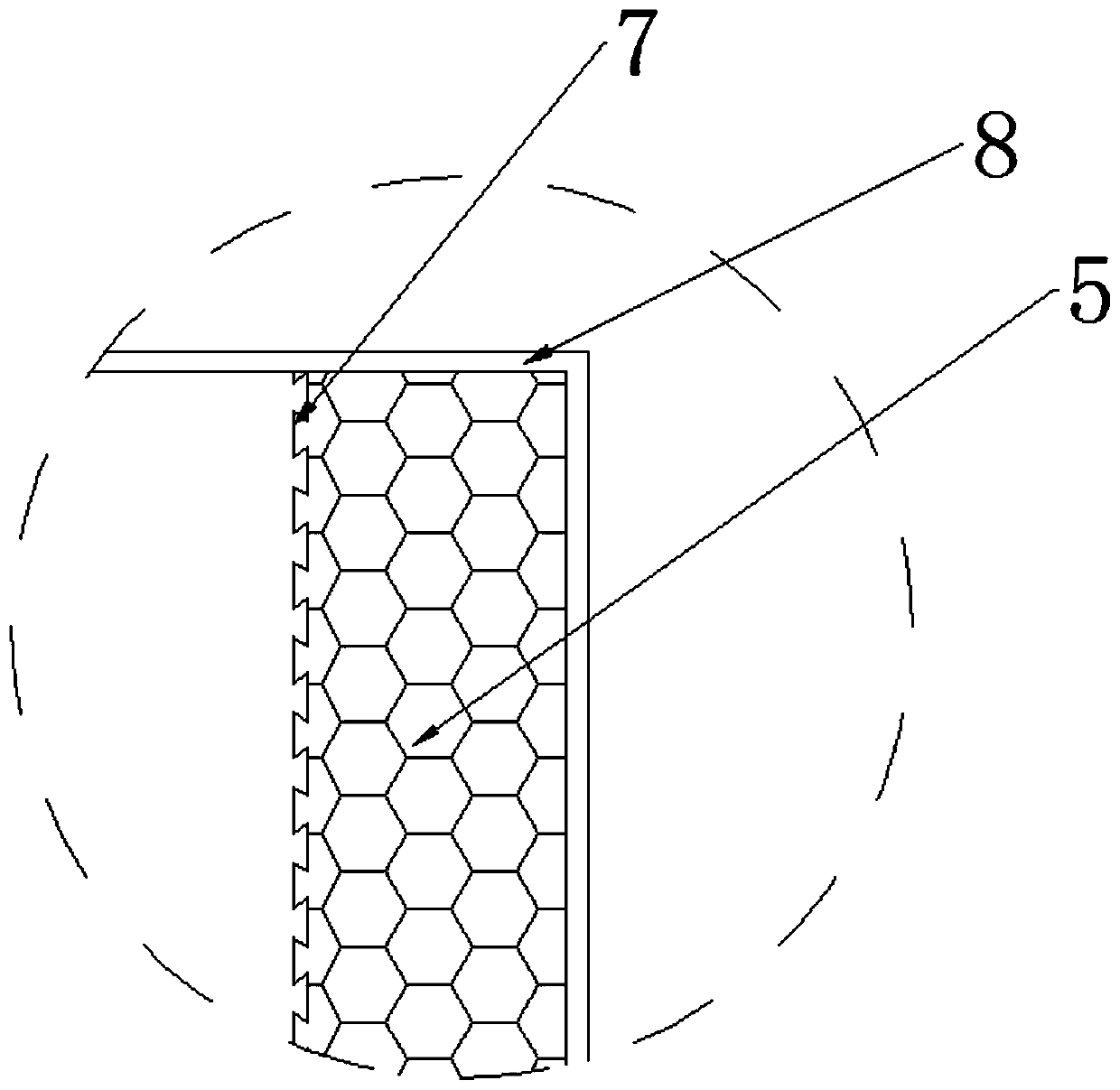

[0025] Such as Figure 1-6 As shown, the present invention provides a composite ribbed thermal insulation block on one side. The thermal insulation block is installed at the hot and cold bridge 10, and the exposed part of the hot and cold bridge 10 is bonded with the thermal insulation layer 9 of the cold and hot bridge. In the prior art, the self-weight of the cantilever structure is relatively large, and because it carries the entire insulation block, the density of the block body 1 is much higher than that of the insulation material, so the structural load-bearing requirements are relatively high, and it is difficult to ensure the safety after construction .

[0026] The one-sided thermal insulation block includes a block body 1, connecting ribs 3, cantilevered ribs 2, intercostal thermal insulation material 4 and external thermal insulation material 5, and the block body 1, connecting ribs 3 and cantilevered ribs 2 are integrated structure, the cross-section of the cantil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com