Manufacturing process for jewelry protective film

A production process and technology of protective film, which is applied in the field of production process of jewelry protective film, can solve the problems of darkening of color, jade loss, fading, etc., and achieve the effects of reducing thermal decomposition rate, increasing oxygen index, and inhibiting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

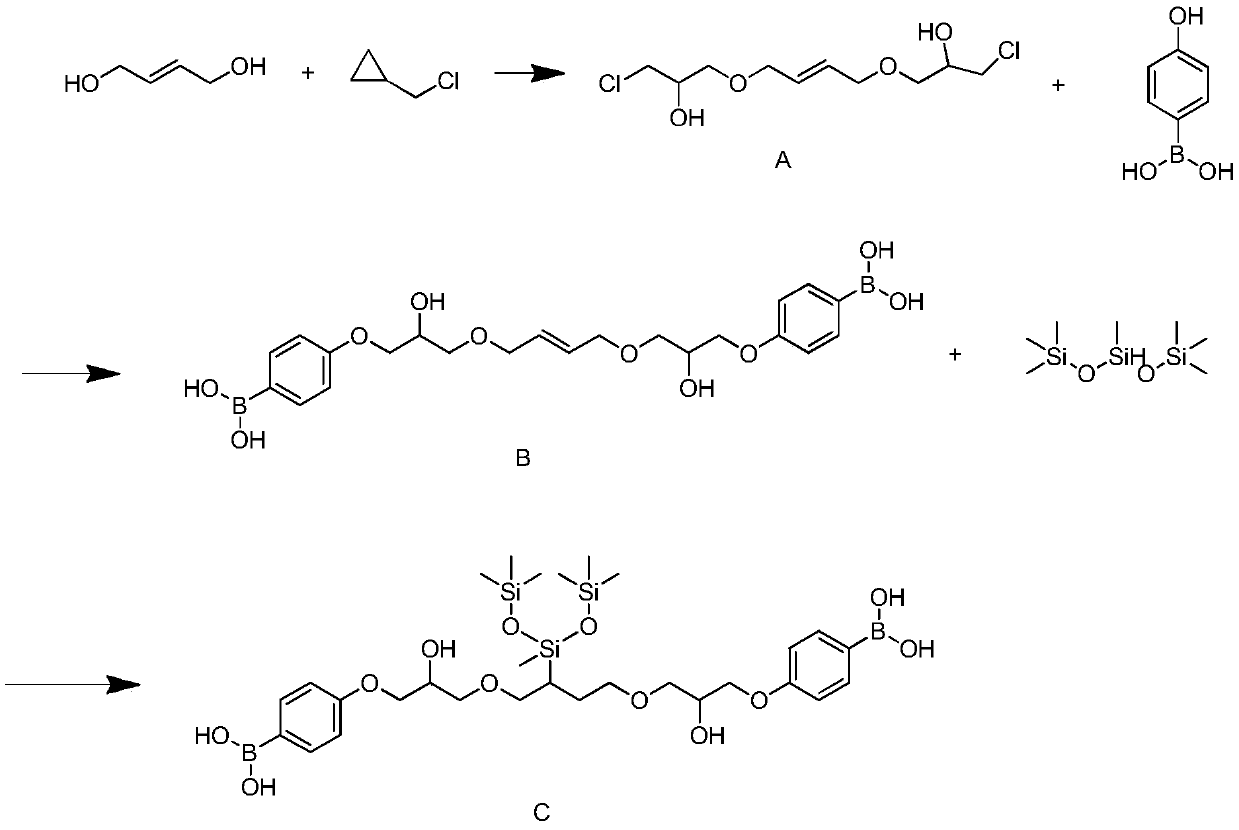

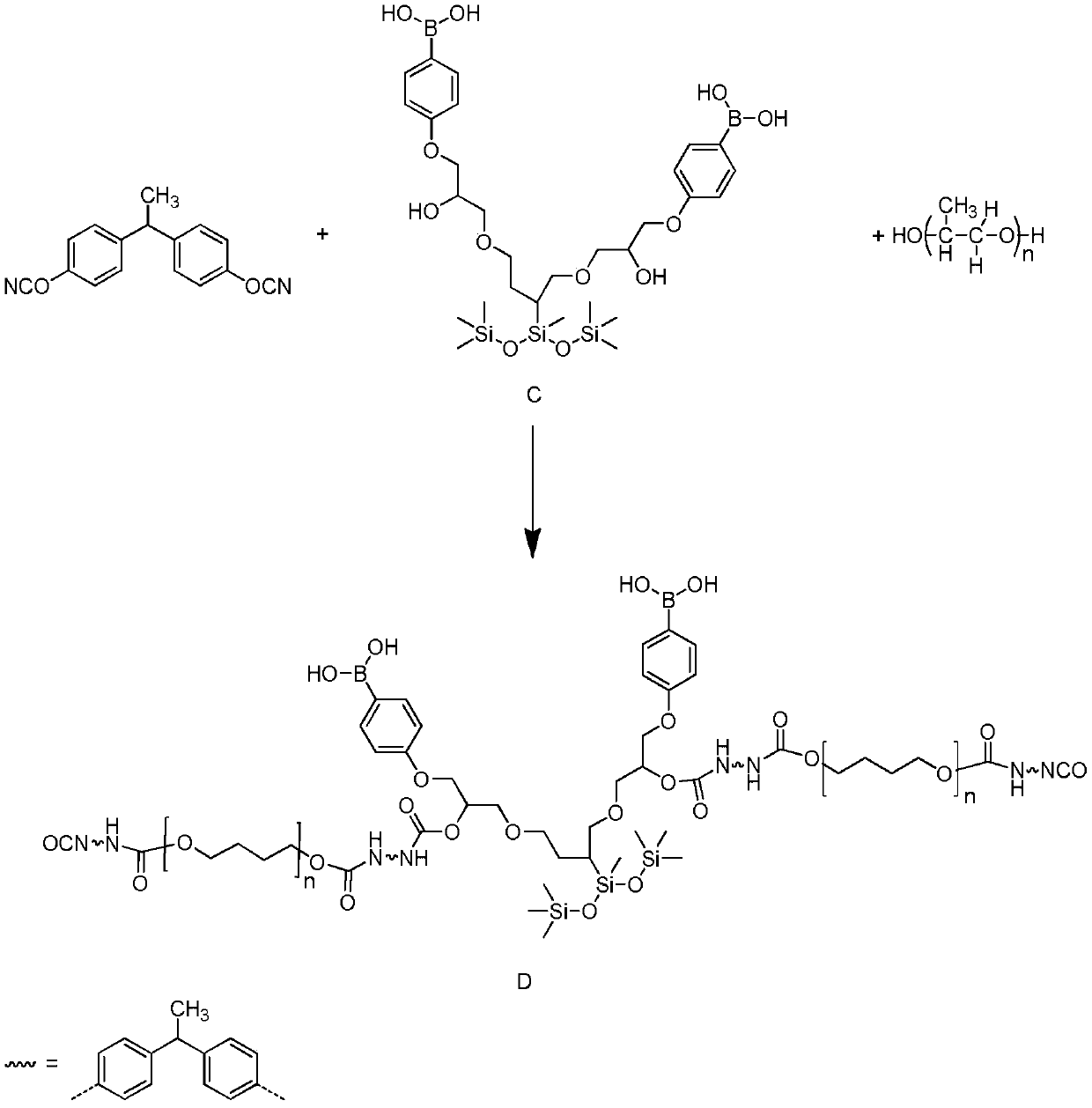

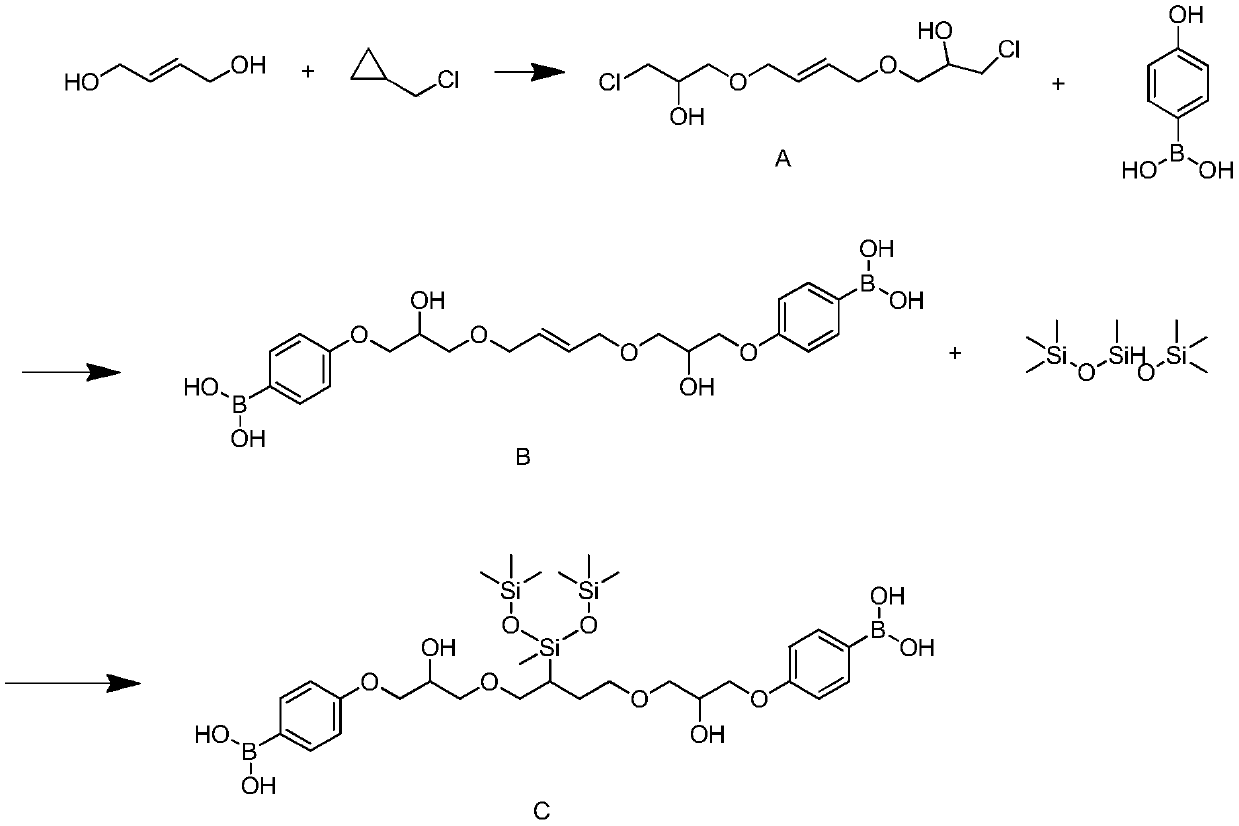

Method used

Image

Examples

Embodiment 1

[0044] A manufacturing process of a jewelry protective film, the protective film is composed of the following raw materials in parts by weight: 100 parts of modified polyurethane, 5 parts of polyethylene glycol and 100 parts of isopropanol;

[0045] The specific production process is as follows: heat the modified polyurethane and polyethylene glycol to 80°C to melt, stir and mix for 30 minutes, then slowly add isopropanol, and cool down to 35°C while stirring to obtain the jewelry protection liquid. At this temperature, Use a spray gun to evenly spray jewelry protective liquid on the surface of jewelry, let it dry naturally for 2 hours, and obtain a jewelry protective film with a thickness of 8-15nm.

Embodiment 2

[0047] A manufacturing process of a jewelry protective film, the protective film is composed of the following raw materials in parts by weight: 100 parts of modified polyurethane, 10 parts of polyethylene glycol and 100 parts of isopropanol;

[0048] The specific production process is as follows: heat the modified polyurethane and polyethylene glycol to 85°C to melt, stir and mix for 30 minutes, then slowly add isopropanol, and cool down to 40°C while stirring to obtain the jewelry protection liquid. At this temperature, Use a spray gun to evenly spray jewelry protective liquid on the surface of jewelry, let it dry naturally for 2 hours, and obtain a jewelry protective film with a thickness of 8-15nm.

Embodiment 3

[0050] A manufacturing process of a jewelry protective film, the protective film is composed of the following raw materials in parts by weight: 100 parts of modified polyurethane, 7 parts of polyethylene glycol and 100 parts of isopropanol;

[0051] The specific production process is as follows: heat the modified polyurethane and polyethylene glycol to 82°C to melt, stir and mix for 30 minutes, then slowly add isopropanol, and cool down to 39°C while stirring to obtain the jewelry protection liquid. At this temperature, Use a spray gun to evenly spray jewelry protective liquid on the surface of jewelry, let it dry naturally for 1 hour, and obtain a jewelry protective film with a thickness of 8-15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com