Porous ceramsite concrete as well as preparation method and application thereof

A technology of porous pottery and concrete, applied in the field of building construction, can solve the problems of affecting construction quality, broken density and stratification, etc., and achieve the effects of low density, low apparent density, and poor thermal insulation and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

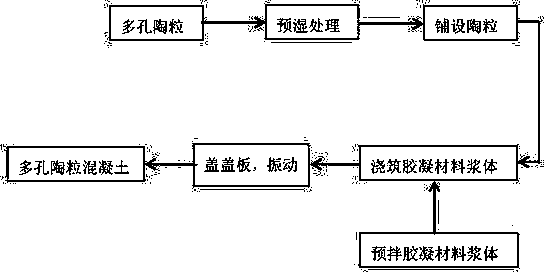

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of porous ceramsite concrete comprises the following steps:

[0029] Step 1: Select porous ceramsite with a particle size of 5mm and pre-wet it in water at 20°C for 1 hour to obtain wet porous ceramsite;

[0030] Step 2: Weigh the cementitious material (PC325), water, fine aggregate (coarse sand) and polycarboxylate superplasticizer at a mass ratio of 1:0.2:1.3:0.005, and stir the cementitious material and fine aggregate While adding a forced sandstone mixer, stir at 20rpm for 30s, then slowly pour the mixture of water and polycarboxylate superplasticizer into the mixer, stir for 60s to mix evenly, and obtain a cementitious material slurry;

[0031] Step 3: According to the mass ratio of cementitious material slurry to porous ceramsite: 1:0.05, weigh the wet porous ceramsite obtained in step 1 and the cementitious material slurry obtained in step 2, and then spread the wet porous ceramsite evenly on the concrete After pouring the cementitious mat...

Embodiment 2

[0033] The preparation method of porous ceramsite concrete comprises the following steps:

[0034] Step 1: Select porous ceramsite with a particle size of 5mm and pre-wet it in water at 20°C for 1 hour to obtain wet porous ceramsite;

[0035] Step 2: Weigh the cementitious material (PC425), water, fine aggregate (coarse sand) and polycarboxylate superplasticizer at a mass ratio of 1:0.35:1.62:0.005, and stir the cementitious material and fine aggregate While adding a forced sandstone mixer, stir at 30rpm for 30s, then slowly pour the mixture of water and polycarboxylate superplasticizer into the mixer, stir for 60s to mix evenly, and obtain a cementitious material slurry;

[0036] Step 3: According to the mass ratio of cementitious material slurry and porous ceramsite to 1:0.2, weigh the wet porous ceramsite obtained in step 1 and the cementitious material slurry obtained in step 2, and then spread the wet porous ceramsite evenly Concrete mold, pour the cementitious material ...

Embodiment 3

[0038] The preparation method of porous ceramsite concrete comprises the following steps:

[0039] Step 1: Select porous ceramsite with a particle size of 8mm and pre-wet it in water at 20°C for 1 hour to obtain wet porous ceramsite;

[0040] Step 2: Weigh the cementitious material (PC425), water, fine aggregate (coarse sand) and polycarboxylate superplasticizer at a mass ratio of 1:0.2:1.32:0.01, and stir the cementitious material and fine aggregate While adding a forced sandstone mixer, stir at 40rpm for 30s, then slowly pour the mixture of water and polycarboxylate superplasticizer into the mixer, stir for 60s to mix evenly, and obtain a cementitious material slurry;

[0041]Step 3: According to the mass ratio of cementitious material slurry and porous ceramsite: 1:0.15, weigh the wet porous ceramsite obtained in step 1 and the cementitious material slurry obtained in step 2, and then spread the wet porous ceramsite evenly on the concrete mold, and pour the cementitious ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com