Plane winding machine

A winder and plane technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of film waste and unusability, and achieve the goal of reducing resource waste, improving pass rate, and cutting flat and beautiful Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

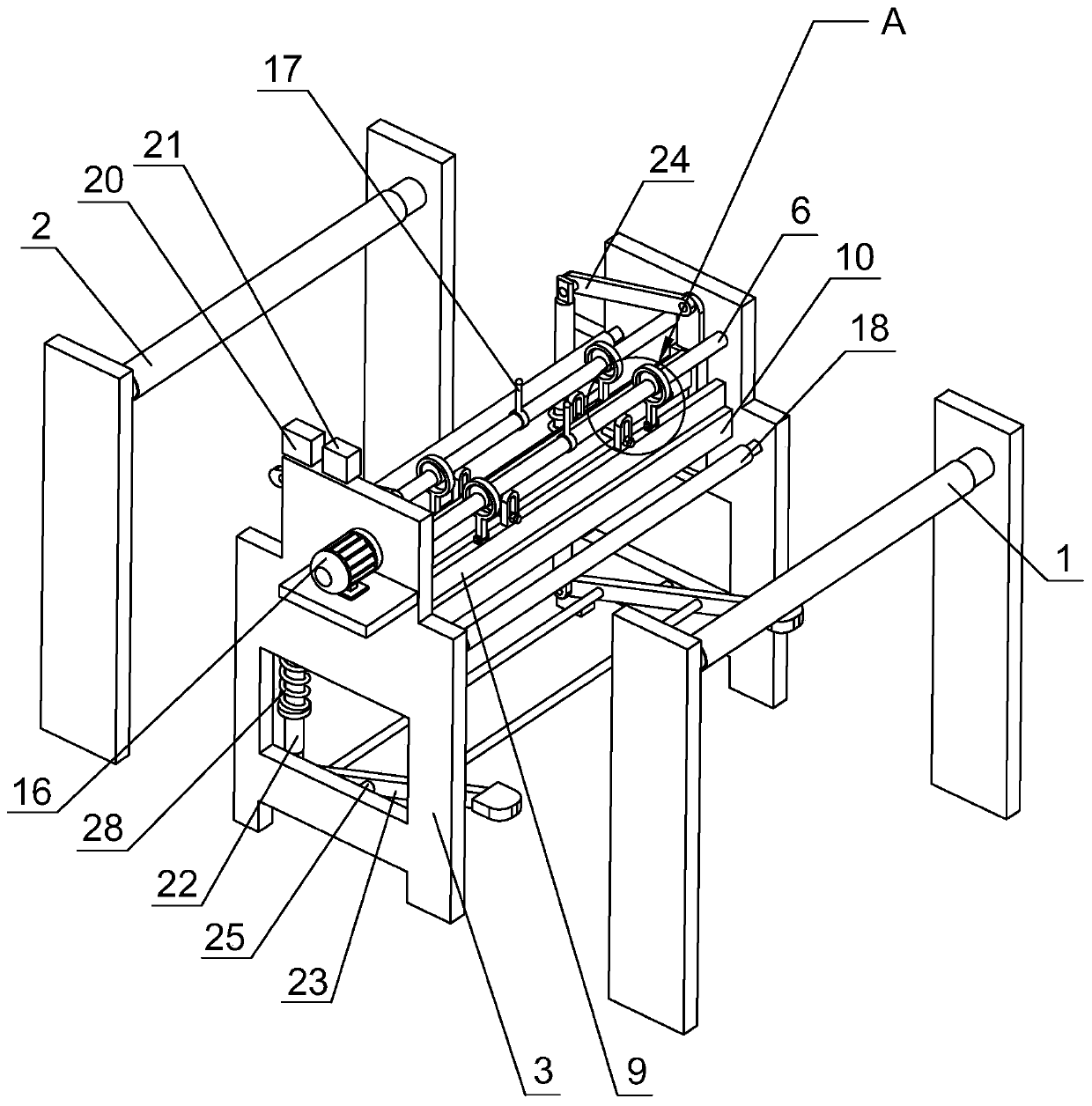

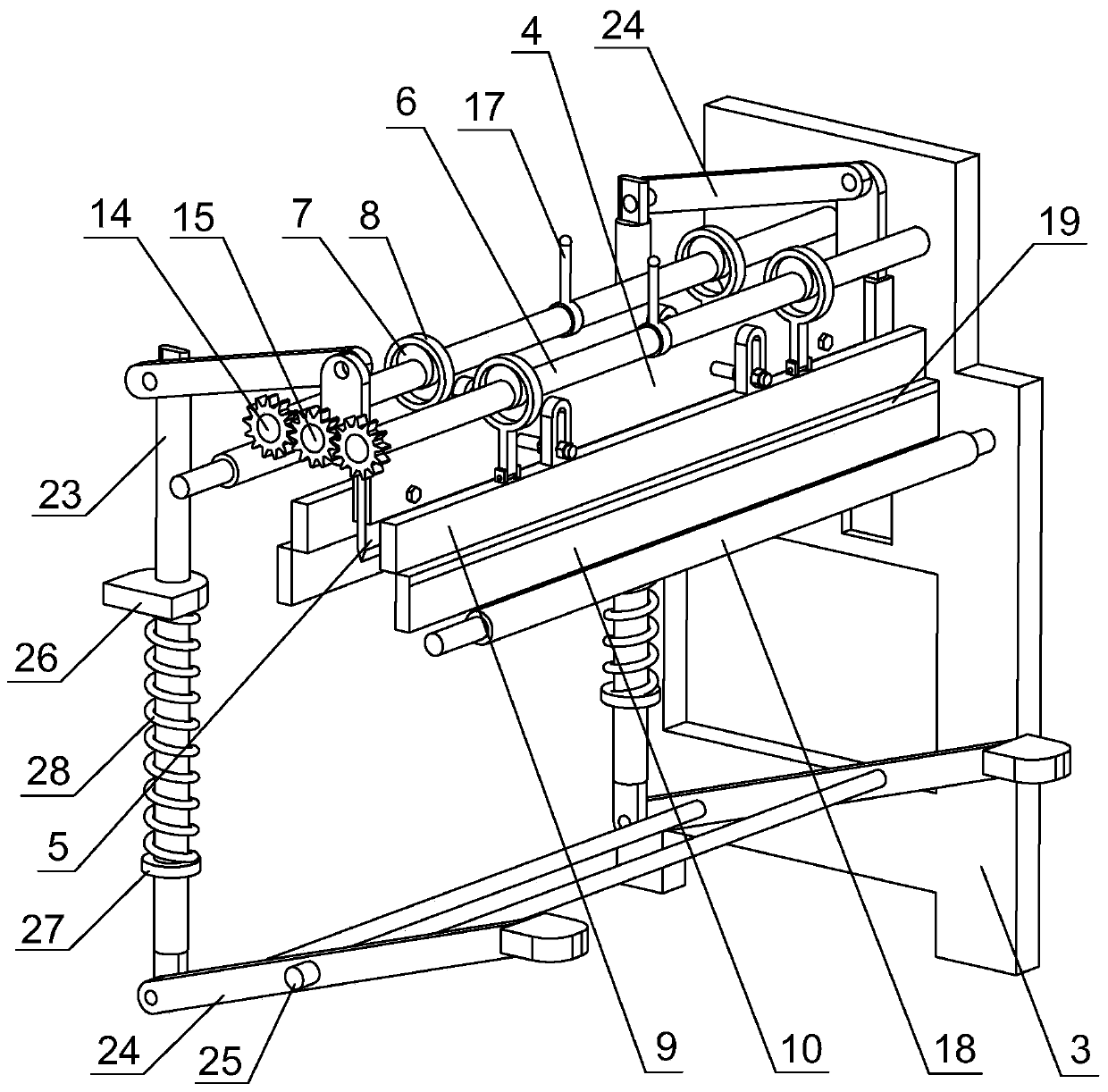

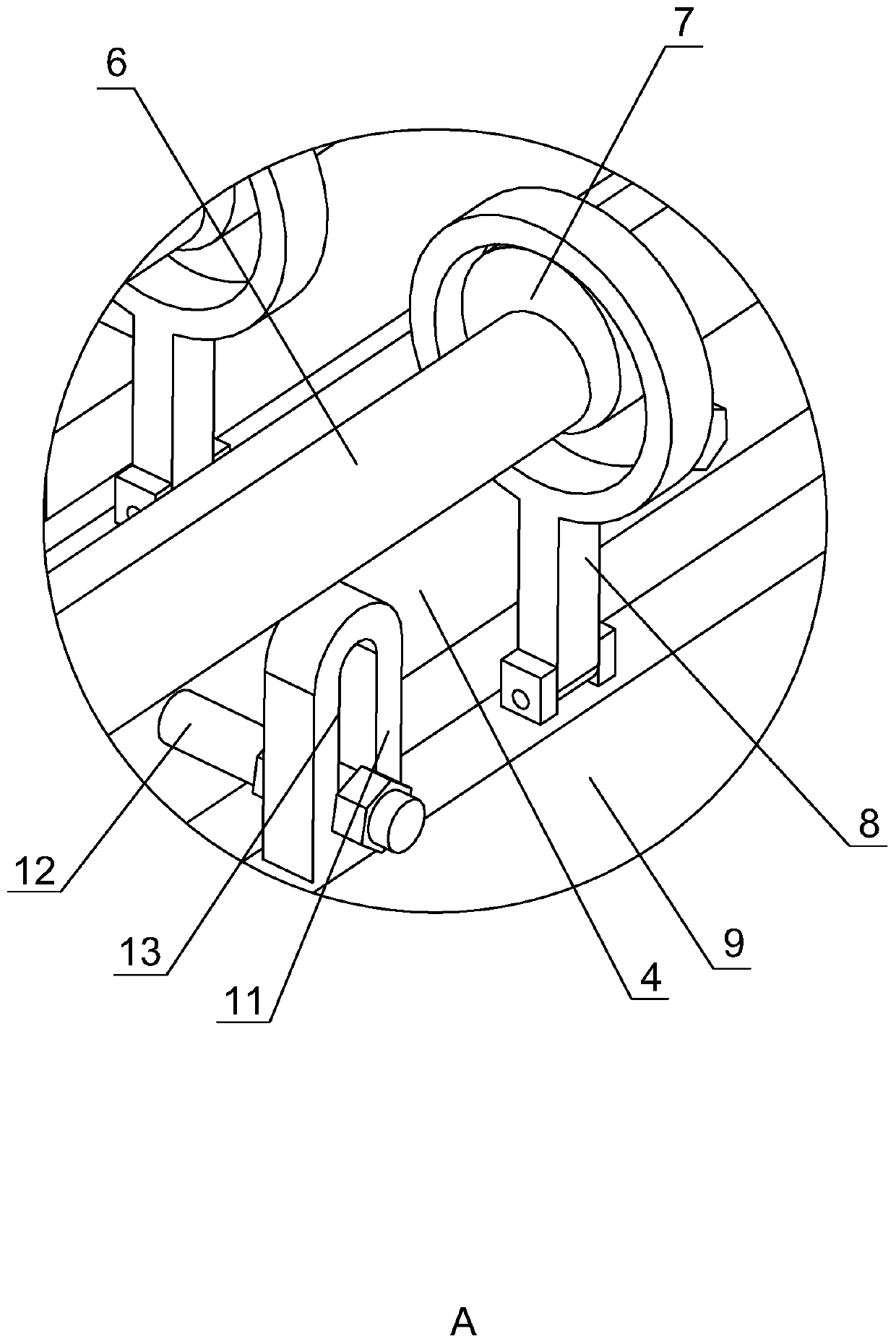

[0035] refer to figure 1 , is a plane winder disclosed by the present invention, comprising an unwinding roller 1 and a winding roller 2 for winding a film, the axis of the winding roller 2 is arranged parallel to the axis of the unwinding roller 1, and the unwinding roller Frame 3 is fixed between 1 and winding roller 2. refer to figure 2 , the inside of the frame 3 is provided with a knife rest 4 for lifting, one side of the knife rest 4 is fixedly embedded with a cutting knife 5, the cutting knife 5 extends along the length direction of the knife rest 4, and the blade of the cutting knife 5 faces away from the knife One side of rack 4 is set. The cutting knife 5 is used to cut the film. After the film winding on the winding roller 2 is completed, the lifting knife rest 4 drives the cutting knife 5 to descend, thereby cutting the film directly below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com