Polyurethane composite material mixing machine for producing automobile roofs

A polyurethane composite material and car roof technology, which is applied in grain processing and other directions, can solve the problems of raw material loss, reduced cleanliness of the machine body, and the influence of raw material stirring and mixing, and achieve the effects of reducing raw material loss, fully stirring and mixing, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

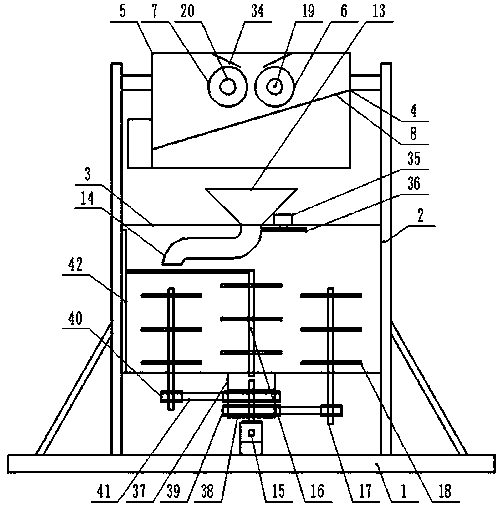

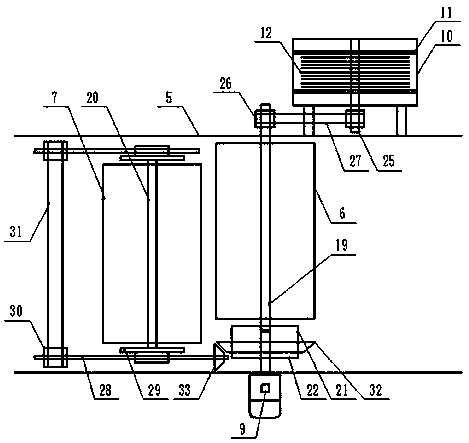

[0014] Example 1: see figure 1 , figure 2 , image 3 Now, a description will be given of a polyurethane composite mixing machine for producing automobile roofs provided by the present invention, which includes a foundation base 1 and a vertical fixing frame 2 evenly arranged on the upper middle side of the foundation base 1. The vertical fixing frame 2 A mixing box 3 is fixed between the lower ends, and a material preparation mechanism 4 is arranged between the upper ends of the vertical fixing frame 2. The material preparation mechanism 4 includes a material preparation box 5, and the upper end of the inner cavity of the material preparation box 5 is spaced parallel and horizontally. Some active grinding rollers 6 and driven grinding rollers 7, the inclined vibrating mesh screen 8 provided in the preparation box 5 and below the position of the active grinding roller 6, on the outer end wall of the preparation box 5 and corresponding to the position of the active grinding rolle...

Embodiment 2

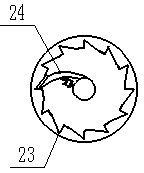

[0015] Example 2: see figure 1 , figure 2 , image 3 Now, the present invention provides a description of a polyurethane composite material mixing machine for the production of automobile roofs. The lower end of the vertical fixing frame 2 and the upper end of the foundation base 1 are respectively provided with reinforcing ribs. A driving shaft 19 and a driven shaft 20 are arranged in parallel and horizontally at the upper end of the inner cavity of the preparation box 5, and the driving grinding roller 6 and the driven grinding roller 7 are respectively sleeved outside the driving shaft 19 and the driven shaft 20. The output shaft of the first motor 9 movably extends into the preparation box 5, the extension end of the output shaft of the first motor 9 is sheathed with a cylindrical transmission frame, and the inner port diameter of the cylindrical transmission frame is larger than that of the first The cross-sectional diameter of the output shaft of the motor 9, the cylindr...

Embodiment 3

[0016] Example 3: See figure 1 , figure 2 Now, the present invention provides a description of a polyurethane composite material mixing machine for producing automobile roofs. The first screw 25 and the driving shaft 19 are arranged parallel to each other at intervals, and the first screw 25 , The protruding ends of the active shaft 19 are respectively sleeved with a first pulley 26, a first belt 27 is sleeved between the outside of the first pulley 26, and the extrusion plate 11 is uniformly opened with through holes, respectively, The air filter housing 10 is provided with an air inlet and an air outlet on both end walls along the length direction of the first screw 25, respectively, the vertical fixing frame 2 is provided with a heating device, and the air inlet passes The pipe is in communication with the outlet end of the preparation box 5, the exhaust port is communicated with the inlet end of the heating device through the pipe, and the inlet end of the preparation box 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com