Button assembling equipment

A technology for assembling equipment and buttons, applied to buttons, metal processing equipment, fasteners, etc., can solve the problems of low production efficiency, high production cost, automatic blanking, and difficulty in pressing, so as to achieve stable and reliable movements and a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

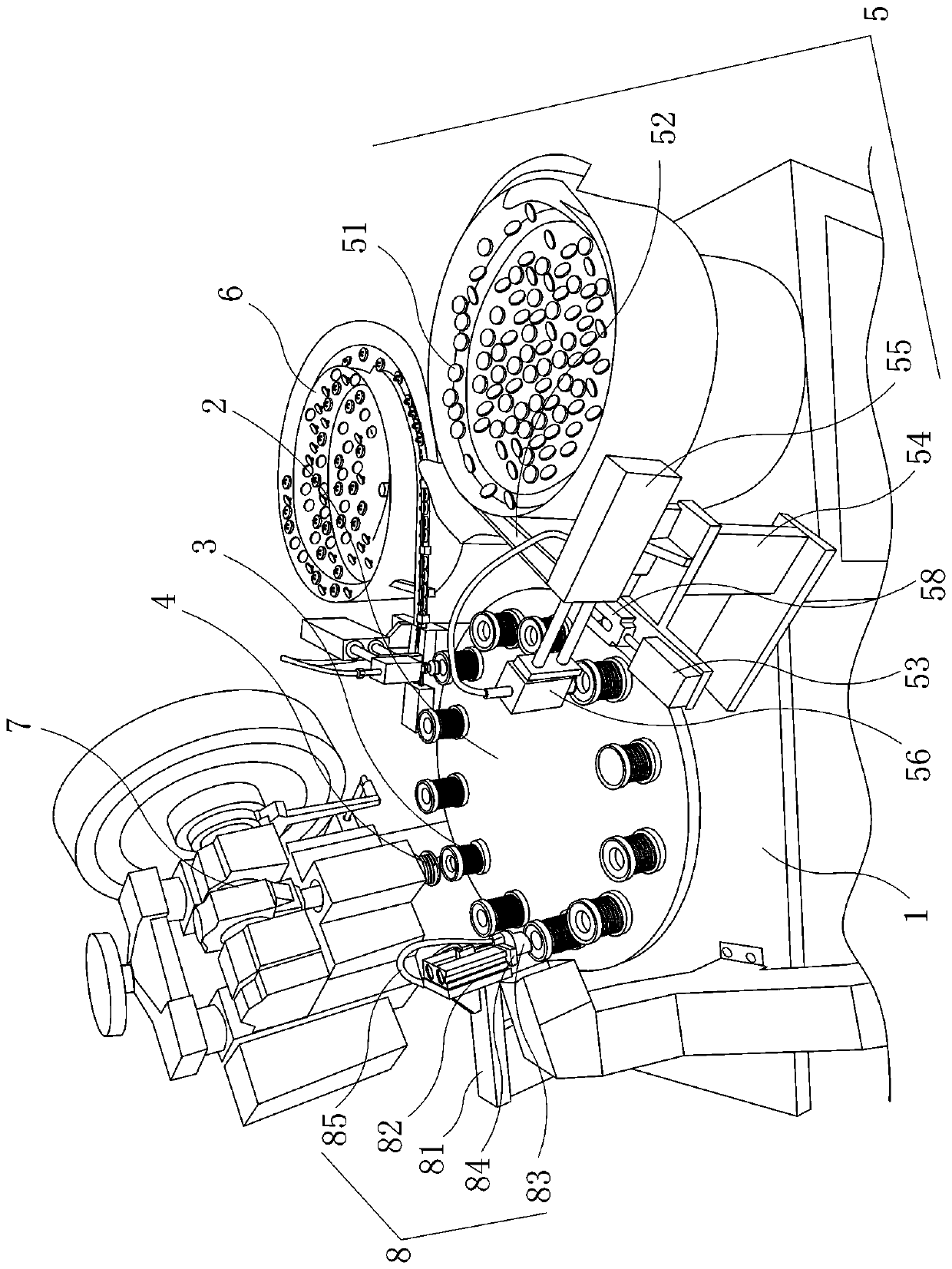

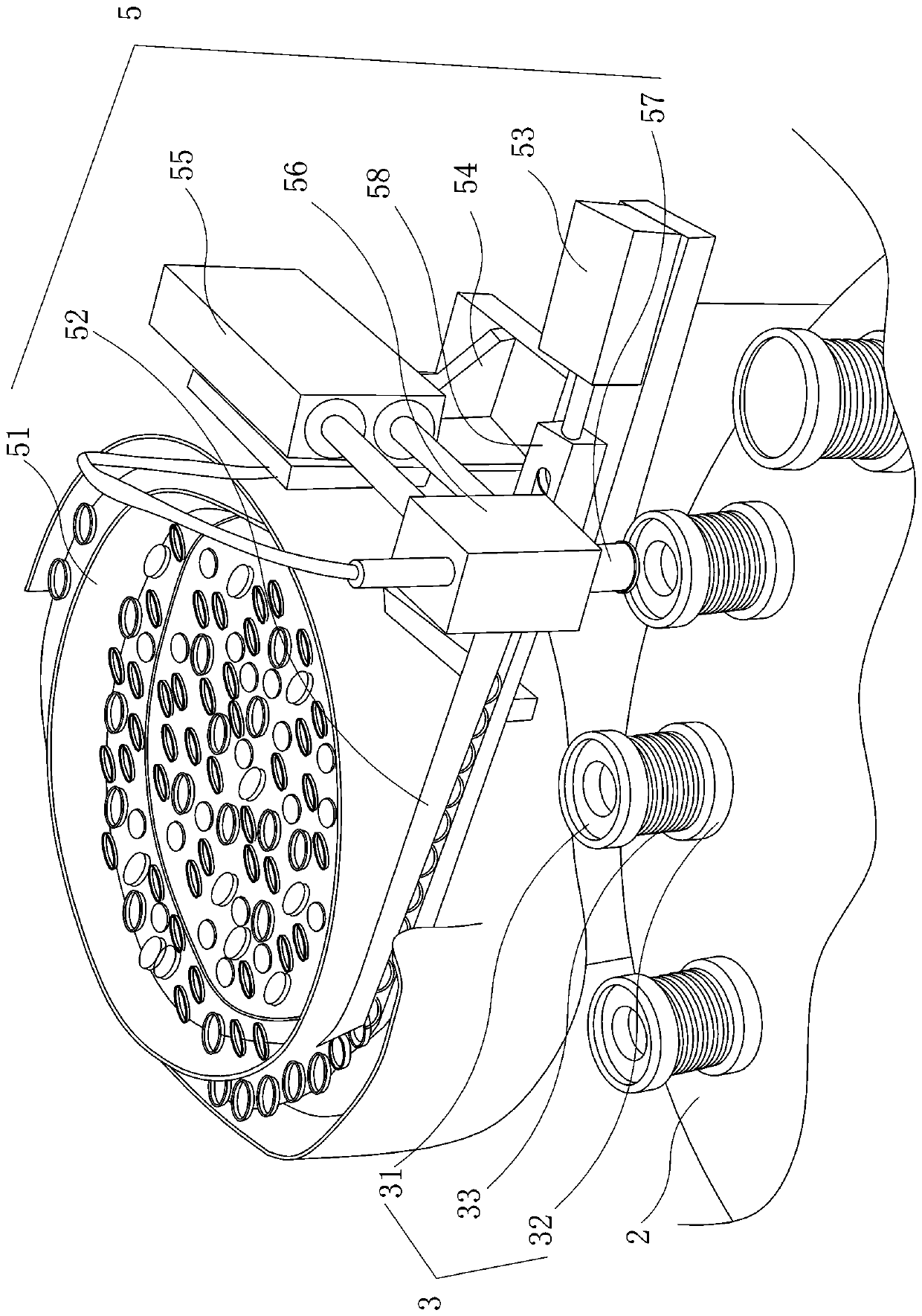

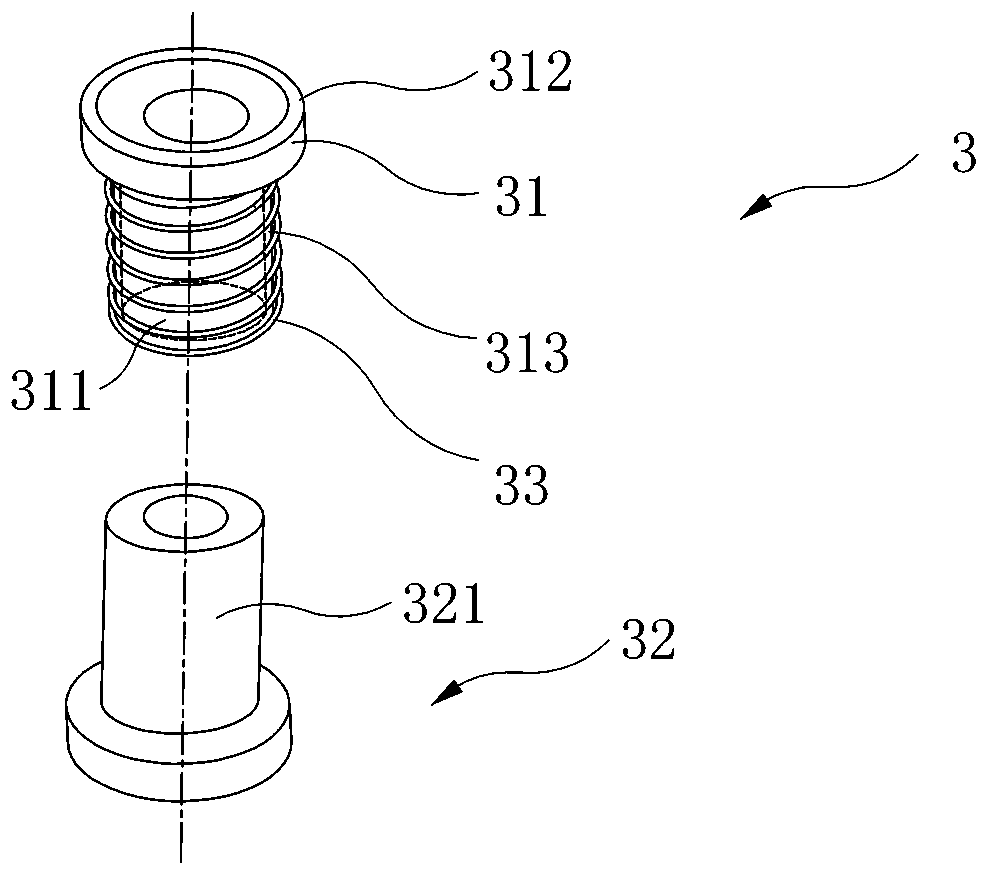

[0018] Such as Figure 1 to Figure 6 As shown, the present invention is a button assembly equipment, including a frame 1, a turntable 2, a plurality of assembly bases 3, a punch mechanism 4, a button shell vibrating feeding device 5, a button body vibrating feeding device 6, a punching machine 7, and a blanking machine. Institution8.

[0019] The turntable 2 is rotatably installed on the frame 1, and a plurality of assembly bases 3 are equidistantly and spacedly installed on the table surface of the turntable 2, the buckle shell vibrating feeding device 5, the button body vibrating feeding device 6, the punching machine 7, The blanking mechanism 8 is arranged around the turntable 2 according to the assembly process; the punch 7 is installed on one side of the turntable 2, the punch mechanism 4 is installed on the punch head of the punch press, and one of the punch mechanism 4 and a plurality of assembly bases 3 The assembly bases 3 are opposite to each other to form a pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com