Finish machining system and finish machining method for reducing anisotropy of metal material

A technology of anisotropy and metal materials, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems that the anisotropy of materials cannot be improved, the rolling direction does not change, and the rolling stock cannot be rolled, etc. Achieve the effects of improving plasticity, reducing the tendency of side cracks, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

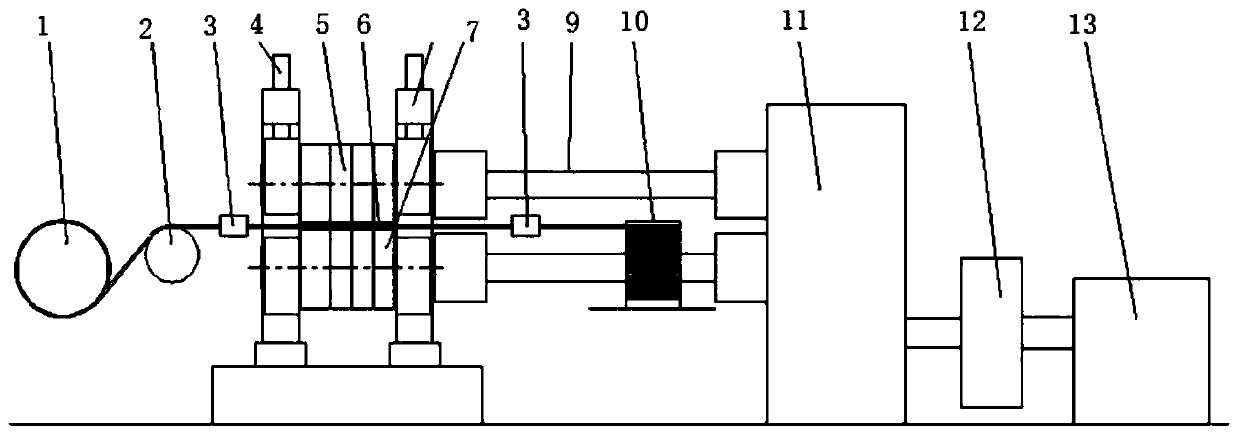

[0064] Such as figure 1 , figure 2 , Figure 9 with Figure 10 As shown, in this embodiment, a finishing system for reducing the anisotropy of metal materials consists of a two-roll rolling mill 14 (including an upper work roll 5, a lower work roll 8, a rolling mill archway 7, and a pressing device 4), a longitudinal The position control device 3, the rolling piece lateral feed control device 1, the speed divider 11 and the driving device 13 are used for rolling narrow rolling pieces.

[0065] In this embodiment, four plane segments 15 are correspondingly provided on the roll surfaces of the upper work roll 5 and the lower work roll 8 , and the rest are cylindrical roll surfaces 16 . The plane section 15 and the cylindrical roll surface 16 on the upper work roll 5 and the lower work roll 8 cooperate to form regular and spaced large roll gap areas and small roll gap areas along the circumferential direction of the roll surfaces.

[0066] In this embodiment, the rotating sp...

Embodiment 2

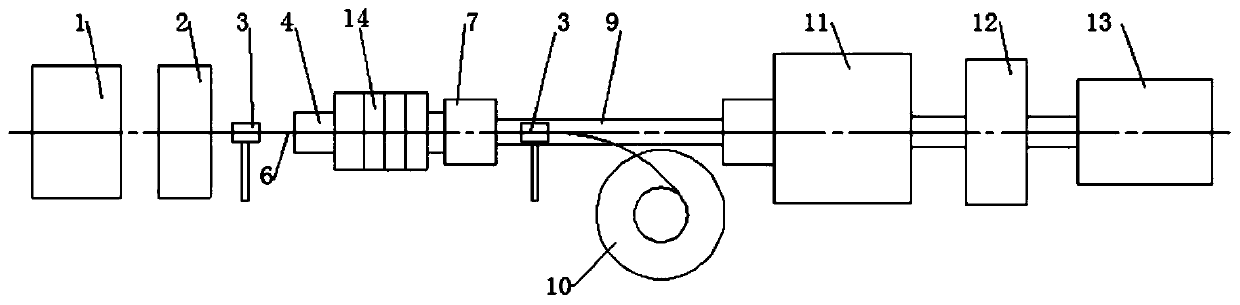

[0072] Such as Figure 4-Figure 6 , Figure 9 with Figure 10 As shown, in this embodiment, a finishing system for reducing the anisotropy of metal materials consists of a two-roll mill 14 (including an upper work roll 5, a lower work roll 8, a mill archway 7 and a pressing device 4), a longitudinal It consists of a position control device 3 , a rolling piece lateral feed control device 1 , a speed divider 11 and a driving device 13 . It is suitable for rolling the rolled pieces with large thickness and width and not easy to bend.

[0073] In this embodiment, the rotating speed of the upper work roll 5 and the lower work roll 8 is 60 rpm, the roll diameter is 300 mm, and the width of the roll surface is 100 mm. The width of the roll surface is divided into two parts, and each part is 50 mm wide. Two plane sections 15 are arranged on the roller surface along the circumferential direction, and the rest are cylindrical roller surfaces 16 . The circumferential length of each p...

Embodiment 3

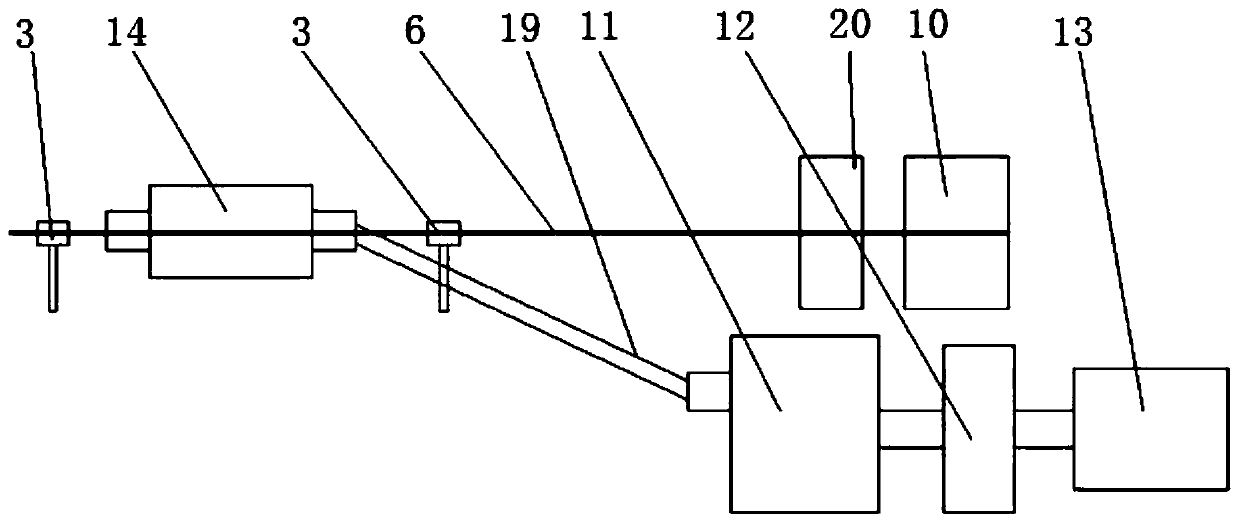

[0080] Such as Figure 7-Figure 10 As shown, in this embodiment, a finishing system for reducing the anisotropy of metal materials consists of a two-roll rolling mill 14 (including an upper work roll 5, a lower work roll 8, a rolling mill archway 7 and a pressing device 4), a longitudinal It consists of a position control device 3 , a rolling piece lateral feed control device 1 , a speed divider 11 and a driving device 13 .

[0081] In this embodiment, the rotating speed of the upper and lower work rolls 5 and 8 is 30 rpm, the roll diameter is 300 mm, and the roll surface width is 100 mm. The roll surface is divided into two parts along the width direction, and each part is 50 mm wide. The roll surface is divided into 4 sections of planar sections 15 and 4 sections of cylindrical roll surfaces 16 along the circumference, wherein the circumferential length of each section of planar section 15 is 108 mm, and the circumferential length of each section of cylindrical roll surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com