Coal tar-based ultra-high specific surface area nitrogen-containing porous carbon and preparation method and application thereof

A technology of ultra-high specific surface area and coal tar, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of poor dye adsorption effect and achieve rich variety and quantity, The effect of increasing the utilization rate and reducing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] As a further improvement of the present invention, the preparation method comprises the following steps:

[0042] (1) Take coal tar, calcium oxide and potassium hydroxide respectively, place in a grinder and grind to make the materials fully mixed to obtain a reactant;

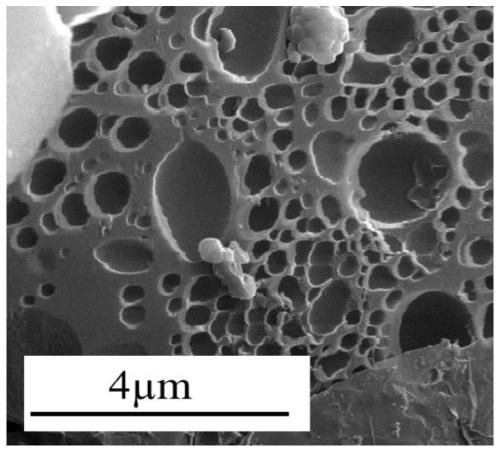

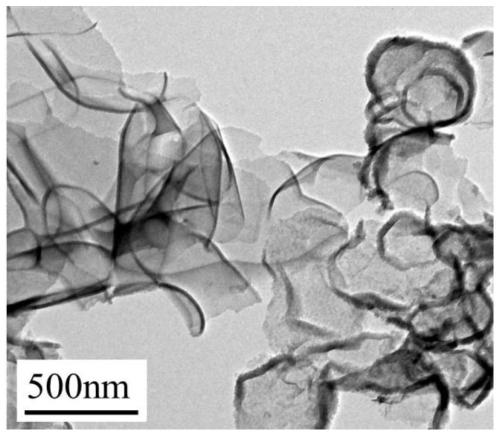

[0043](2) Put the obtained reactant into the crucible, then put the crucible into the tube furnace, slowly and uniformly pass nitrogen gas to exhaust the air, slowly and uniformly raise the temperature to 850°C-900°C, and keep the constant temperature at 55 Cool down after -65min, and when it is down to room temperature, turn off the power and nitrogen, take out the crucible, take out the product, grind, pickle, put it on a magnetic stirrer and stir it evenly, then let it stand still, wash it to neutral, dry, and sieve to get the coal Tar-based porous carbon; preferably, the nitrogen flow rate is 6mL / min; the air in the device can be exhausted by ventilating for 30 minutes; the heating rate is preferabl...

Embodiment 1

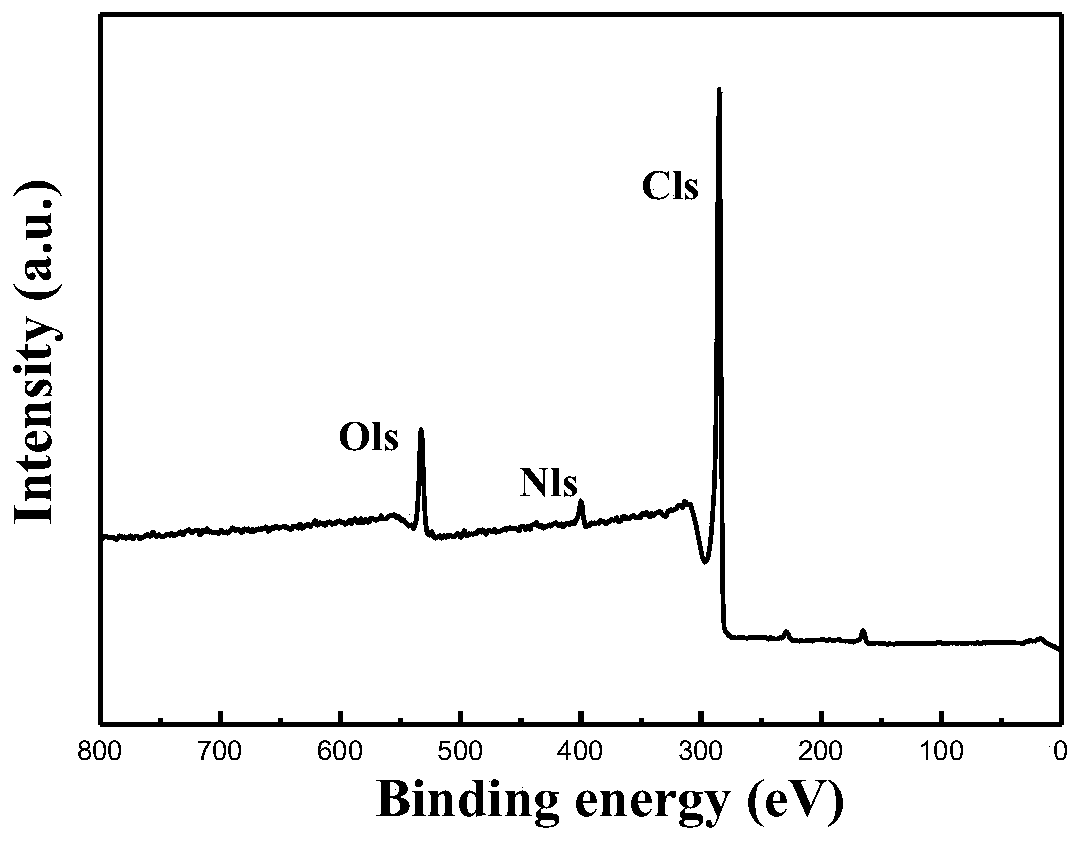

[0054] This embodiment provides a coal tar-based ultra-high specific surface area nitrogen-containing porous carbon for dye adsorption. The porous carbon uses coal tar as a carbon source, calcium oxide as a template, and potassium hydroxide as an activator. Modified by ethylenediamine impregnation. Specific steps are as follows:

[0055] Step 1: Weigh 5g of coal tar, 10g of calcium oxide and 20g of potassium hydroxide respectively, place them in a grinder and grind them, so that the materials are fully mixed to obtain reactants;

[0056] Step 2: Put the obtained reactants into the crucible, then put the crucible into the tube furnace, feed nitrogen gas at a flow rate of 6mL / min, ventilate for 30min to exhaust the air in the device, and then raise the temperature at a rate of 5°C / min Raise the temperature to 900°C, keep the temperature constant for 60 minutes, and then cool down. When the tube furnace drops to room temperature, turn off the power and nitrogen, take out the cru...

Embodiment 2

[0065] This embodiment provides a coal tar-based ultra-high specific surface area nitrogen-containing porous carbon for dye adsorption. The porous carbon uses coal tar as a carbon source, calcium oxide as a template, and potassium hydroxide as an activator. Modified by ethylenediamine impregnation. Specific steps are as follows:

[0066] Step 1: Weigh 5g of coal tar, 10g of calcium oxide and 20g of potassium hydroxide respectively, place them in a grinder and grind them, so that the materials are fully mixed to obtain reactants;

[0067] Step 2: Put the obtained reactants into the crucible, then put the crucible into the tube furnace, feed nitrogen gas at a flow rate of 6mL / min, ventilate for 30min to exhaust the air in the device, and then raise the temperature at a rate of 5°C / min Raise the temperature to 850°C, keep the temperature constant for 60 minutes, and then cool down. When the tube furnace drops to room temperature, turn off the power and nitrogen, take out the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com