A processing technology of waterproof and stain-resistant down jacket

A processing technology and down jacket technology, applied in the field of down jacket processing, can solve the problems of high cost, poor stain resistance and low efficiency of down jackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

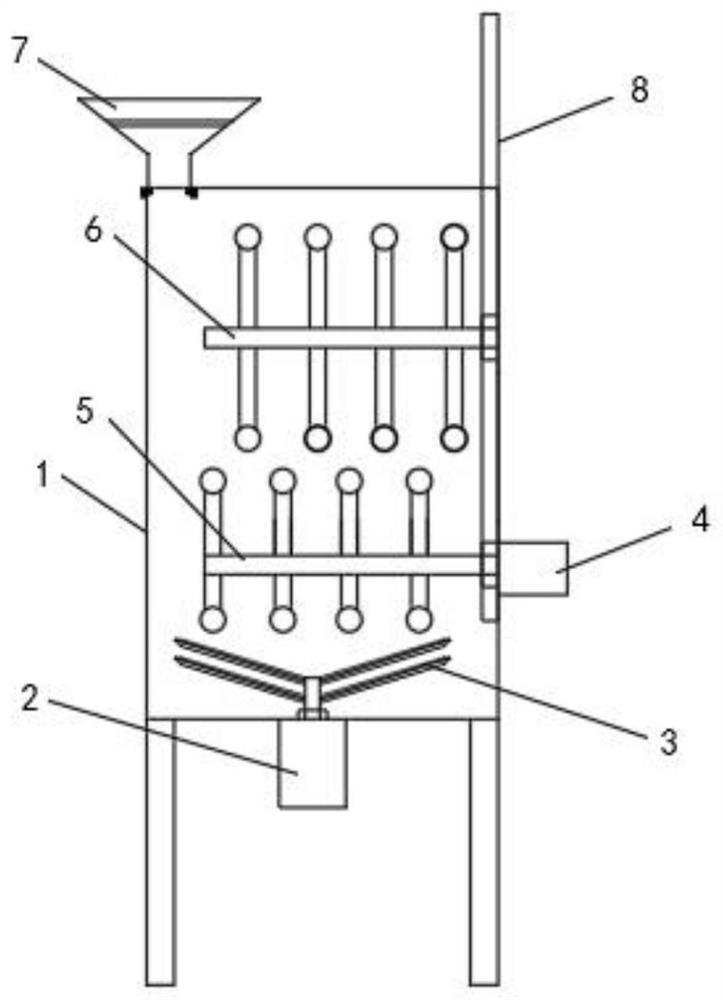

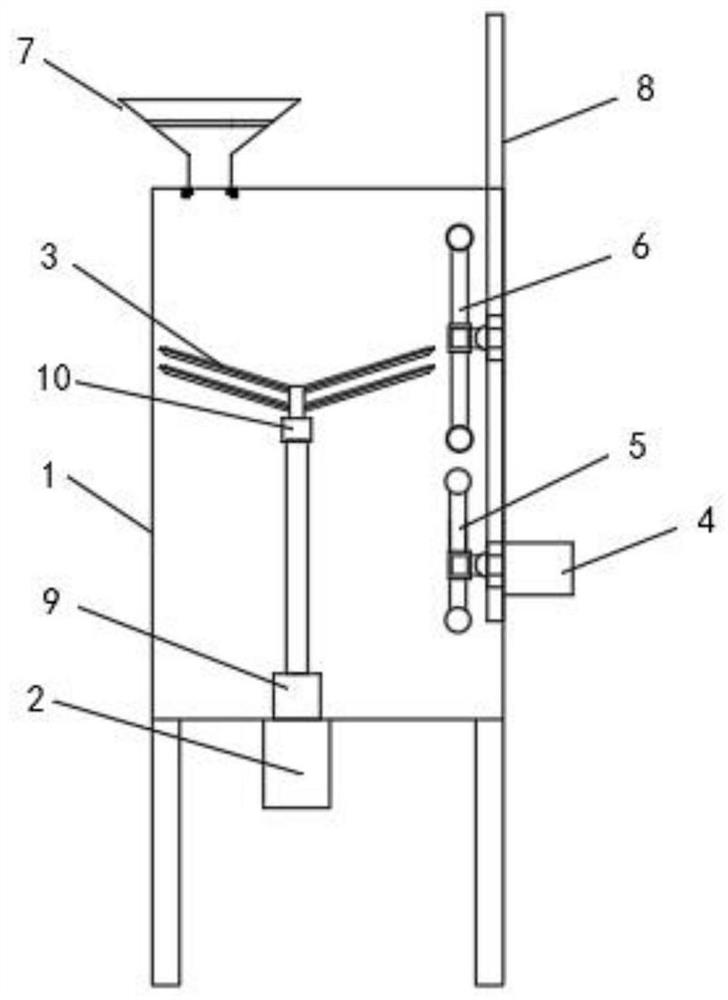

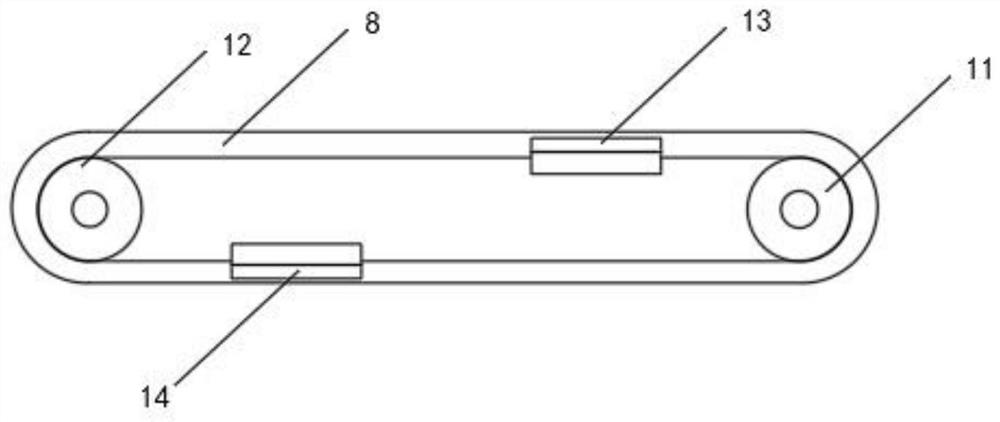

[0033] like Figure 1-4 As shown, a processing technology of a waterproof and stain-resistant down jacket, the waterproof and stain-resistant down jacket is prepared from the following materials:

[0034] Face cloth, color separation paper, down lining cloth, lining and down;

[0035] The face cloth is composed of bottom cotton and surface dye. The bottom cotton is made of warp and weft. The warp is made of nylon with a fineness of 15D-20D and the warp density is 1000-1005. The weft is made of spandex and the weft density is 950-955; The fineness range of spandex is 20D-30D; the surface dyeing agent is composed of dye, the outer film of the leaves of succulent plants, and viscose. The weight ratio is 1: 1: 1;

[0036]The color separation paper is 2525 white color separation paper; the down lining is made of white 230T flannel-proof cloth; the lining is made of 220T silk lining; the down is made of goose and duck belly feathers, and the ratio of goose and duck belly feathers ...

Embodiment 2

[0051] When the present invention is in use: firstly carry out surface cloth processing, select nylon with a fineness of 15D-20D and spandex with a fineness of 20D-30D, and weave the bottom cotton according to the warp density of 1000-1005 and the weft density of 950-955 , and then, to make the surface layer, select the leaves of three succulent plants, Ji Yunyue, Te Yulian, and Jing Ye, freeze the leaves of the three succulent plants in the refrigerator for 30 minutes, take them out, and soak them in hot water at 65-70°C for 30 minutes When the mesophyll in the leaf is softened, cut the leaf and take out the mesophyll to leave the outer film of the leaf, select three kinds of outer film of the leaf according to the weight ratio of 1:1:1, mix the three kinds of outer film of the leaf and make a fibrous raw material ;

[0052] Subsequently, the fibrous raw materials, dyes, viscose, and water are put into the chassis 1 of the processing equipment from the feed hopper 7 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com