A kind of one-way laminated board construction and installation method

An installation method and technology of laminated slabs, applied in the direction of floor slabs, girders, joists, etc., can solve problems such as difficult insertion and installation, achieve the effect of improving construction speed and saving docking installation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

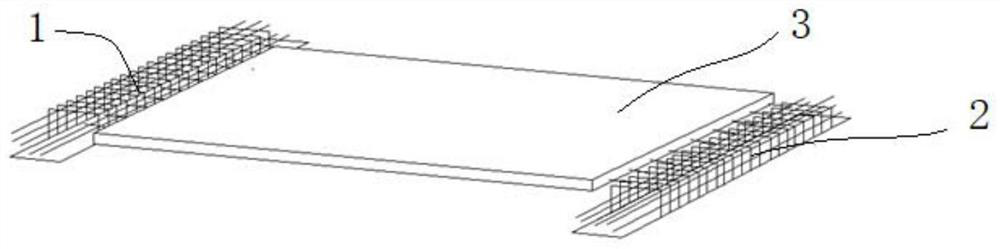

[0019] The construction and installation method of the one-way laminated board 3 provided by this embodiment will be described in detail below with reference to the accompanying drawings.

[0020] A construction and installation method for one-way laminated slabs, comprising the following steps:

[0021] S1. Bind and set up the secondary beam reinforcement on opposite sides, and make the height of the secondary beam reinforcement on one side lower than the height of the secondary beam reinforcement on the other side, wherein the secondary beam reinforcement is mainly composed of transverse reinforcement and surrounding horizontal reinforcement The height difference between the higher side secondary beam reinforcement 1 and the lower side secondary beam reinforcement 2 makes the one-way laminated slab 3 horizontally arranged between the two, and the reinforcement on one side of the one-way laminated slab 3 can be anchored. In the secondary beam reinforcement on the higher side,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com