A Vertical Waterproof Membrane Laying Device and Construction Method for Cast-in-situ Pile Without Fertilizer Groove

A technology of waterproof membrane and cast-in-place piles, which is applied in the direction of protection devices, foundation structure engineering, roof engineering tools, etc., can solve the problems of large safety hazards and low construction efficiency, reduce labor, facilitate construction, and ensure paving quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

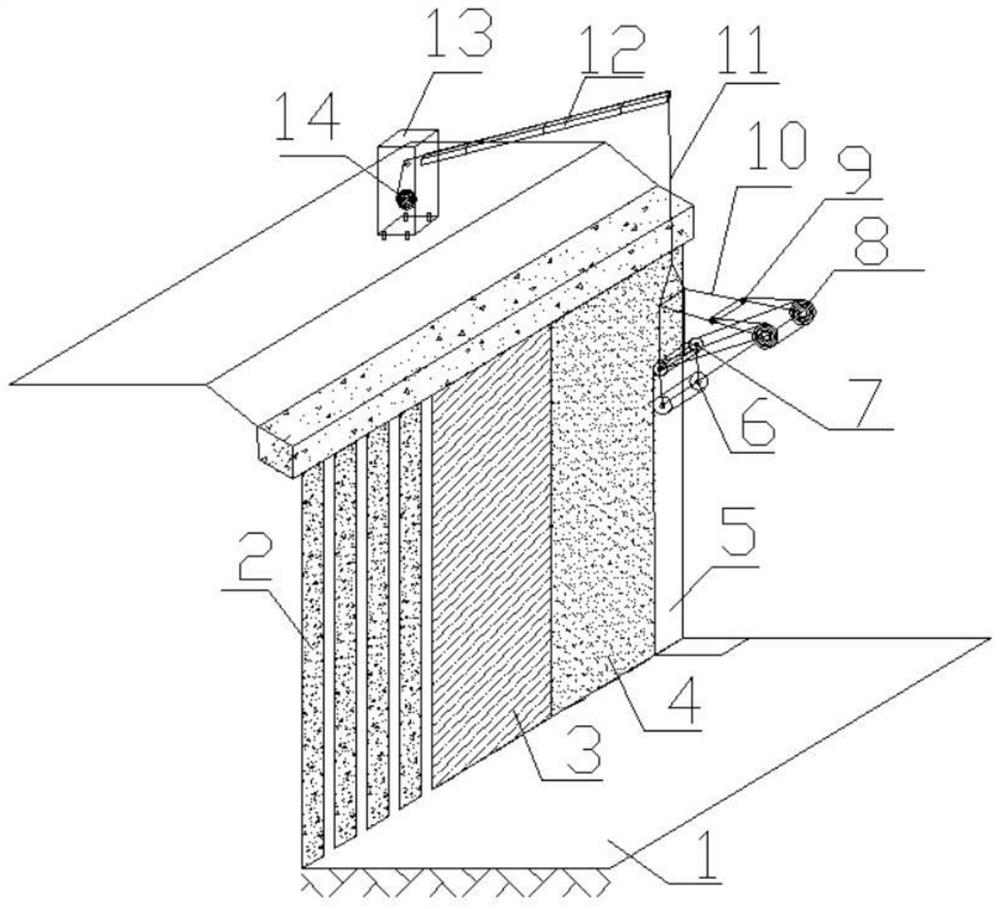

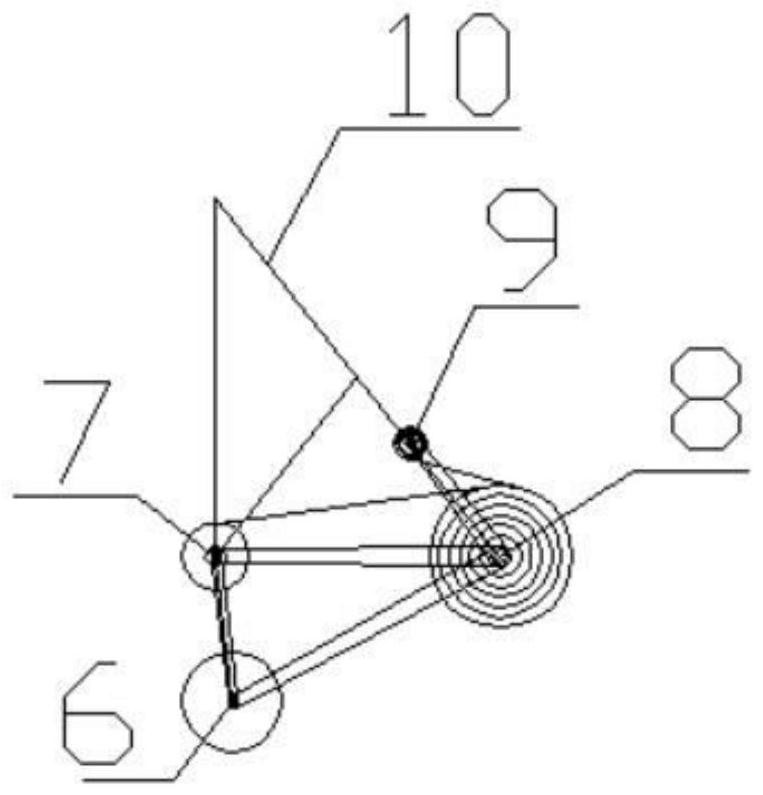

[0033] like Figure 1-7 As shown, a vertical waterproof coiled material laying device for cast-in-situ piles without fertilizer tanks according to the present invention includes a walking trolley 13 and a vertical coiled material laying device; it is characterized in that: the walking trolley 13 includes a telescopic arm 12. Steel wire rope 11 and trolley hoist 14; the vertical coil laying device includes repressing roller 6, coil pressing roller 7, self-adhesive coil roller 8, coil film collecting roller 9, and connecting rod 10 The coiled material paving device is connected and fixed through the connecting rod 10; the vertical coiled material paving device is adjusted by the telescopic arm bar 12; The vertical paving operation of the material, the coil material paving device is connected with the telescopic arm bar 12 through a steel wire rope; the repressing pressure roller 6, the coil material pressure wheel 7, and the self-adhesive coil material roller 8 are all driven wh...

Embodiment 2

[0041] Further selection on the basis of Embodiment 1: the pressure roller 7 of the coiled material is made of rubber material; the roller material of the pressure roller 6 of the recompression is made of rubber, and its diameter is 20cm larger than that of the pressure roller of the coiled material; The 8 rollers of the coiled material roller are made of cast iron; the material of the 9 rollers of the coil film collecting roller is made of cast iron; the lifting capacity of the walking trolley 13 is 2t; the maximum arm length of the telescopic arm 12 is 5m; The spray anchor layer 3 is 8cm thick with hanging net and anchor spray; the leveling layer 4 is leveled with 2cm cement mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com