Water-containing oil residue granulation, pyrolyzation and gasification device and method

A pyrolysis gasification and oil residue technology, which is applied in the direction of chemical instruments and methods, granular/powdered fuel gasification, gasification process, etc., can solve the problem of increased cost of storage oil residue equipment, inability to make good use of it, and waste of resources and other issues to achieve the effects of outstanding economic and environmental value, obvious design, and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

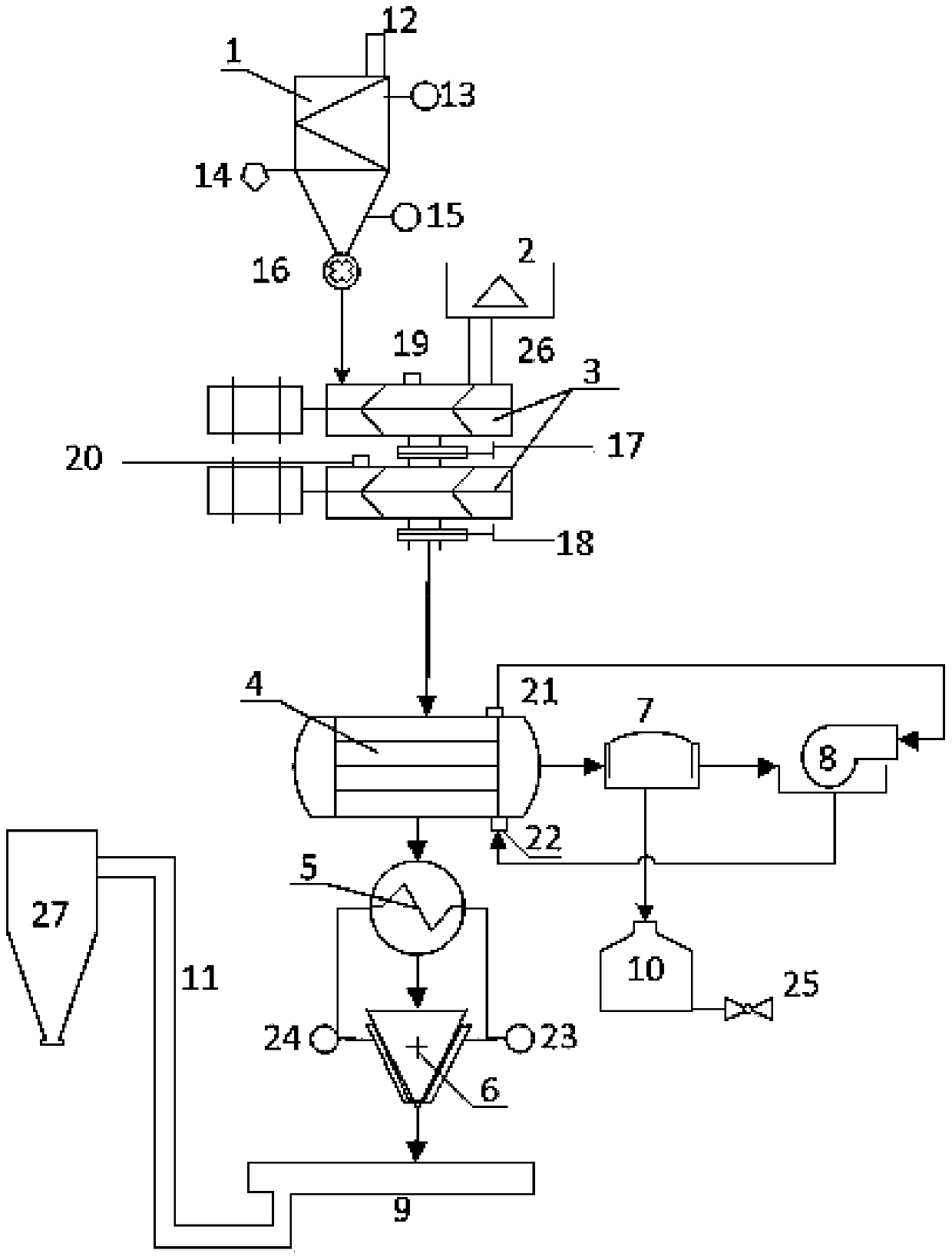

[0045] see figure 1 , the water-containing oil residue granulation repyrolysis gasification device of the present invention includes: a powder quantitative delivery system, an oil residue continuous conveying feeding system, a preliminary mixing system, an oil residue modification heating mixing system, and an oil residue cooling and crushing system. granular system and light oil recovery system;

[0046] The powder quantitative conveying system includes a pyrolysis waste solid powder collector 1, the upper part of the pyrolysis waste solid powder collector 1 bin body is connected to a waste solid powder dust removal unit 12 and a waste solid powder protective gas unit 13, and the bin body The lower part is provided with a waste solid powder quantifier 16 and a waste solid powder fluidization unit 15 , and the bin bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com