A long-acting controlled-release marine antifouling coating

A marine anti-fouling, long-term technology, applied in anti-fouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve the problems of short validity period, non-environmental protection, environmental pollution, etc., to promote reduction and increase Effect, prolong antifouling duration, increase broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

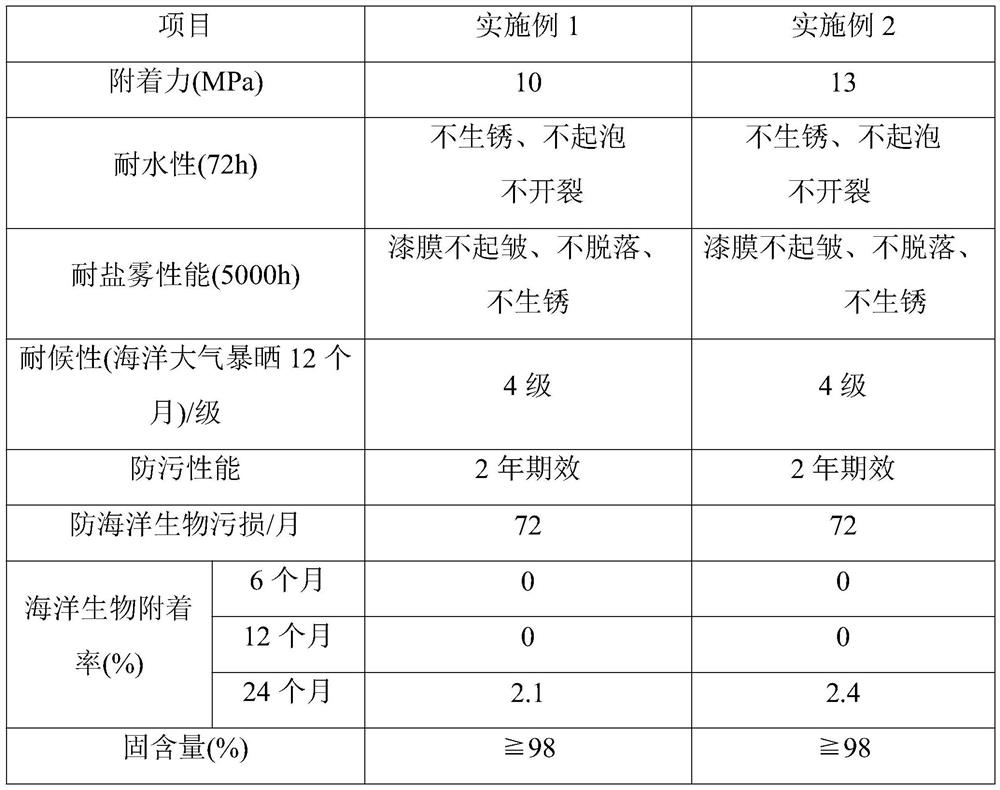

Examples

Embodiment 1

[0019] A long-acting controlled-release marine antifouling coating, comprising: 50 parts by weight of fluorinated acrylate, 33 parts of controlled-release antifouling agent, 16 parts of rosin, 9 parts of polytetrafluoroethylene, 3 parts of paraffin oil, rutile type 18 parts of titanium dioxide, 8 parts of curing agent DN-EB, 4 parts of organic bentonite, 0.3 parts of tributyl phosphate, 24 parts of xylene, 11 parts of butyl acetate;

[0020] The preparation of described controlled-release antifouling agent comprises the following steps:

[0021] (1) Mix 20 parts of biological extracts evenly to obtain a biological antifouling agent, dissolve the biological antifouling agent in 55 parts of xylene, add emulsifier Tween-202 parts, stir and mix evenly to obtain biological antifouling agent oil Mutually;

[0022] (2) Slowly add the oil phase of the bio-antifouling agent to 25g / L sodium alginate aqueous solution, emulsify for 1 hour under stirring conditions to obtain a micro-cross...

Embodiment 2

[0026] A long-acting controlled-release marine antifouling coating, comprising in parts by weight: 53 parts of epoxy resin, 28 parts of controlled-release antifouling agent, 17 parts of rosin, 12 parts of polytetrafluoroethylene, 4 parts of paraffin oil, mica iron oxide 19 parts of ash, 6 parts of curing agent DN-EB, 6 parts of organic bentonite, 0.5 parts of polyacrylamide, 22 parts of xylene, 6 parts of butyl acetate;

[0027] The preparation of described controlled-release antifouling agent comprises the following steps:

[0028] (1) Mix 32 parts of biological extracts evenly to obtain a biological antifouling agent, dissolve the biological antifouling agent in 48 parts of xylene, add 2.5 parts of emulsifier Tween-20, stir and mix evenly to obtain biological antifouling agent oil Mutually;

[0029] (2) Slowly add the oil phase of bio-antifouling agent to 30g / L sodium alginate aqueous solution, and emulsify for 2h under stirring conditions to obtain a micro-crosslinked emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com