Glass composition, millimeter-wave low temperature co-fired ceramic material, and preparation method of ceramic material

A low-temperature co-fired ceramic and glass composition technology, applied in the field of low-temperature co-fired ceramics, can solve the problem of high dielectric loss, achieve excellent dielectric loss, simple preparation process, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A millimeter-wave low-temperature co-fired ceramic material, comprising the following components, calculated by weight percentage:

[0032] Glass composition 44%; Aluminum oxide 56%;

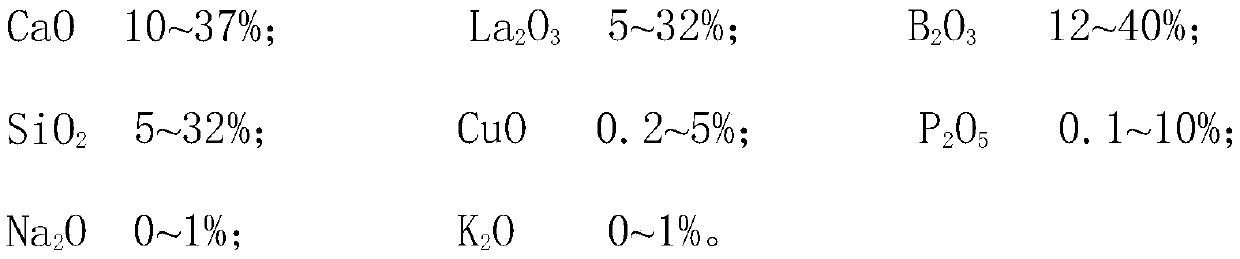

[0033] The glass composition includes the following components, calculated by weight percentage:

[0034]

[0035]

[0036] A method for preparing a millimeter-wave low-temperature co-fired ceramic material: comprising the following steps:

[0037] S1: Preparation of glass composition

[0038] Weigh the above-mentioned glass composition raw materials according to weight percentage; mix and dry the raw materials with a ball mill; put them into a crucible, the temperature of the crucible is 1350°C, and continue to heat the crucible to 1450°C and melt for 60 minutes, then pour it into deionized water to cool Quenching to obtain glass slag, and performing airflow grinding on the glass slag to obtain glass powder, the particle size of the glass powder is D50, and the length is 5-7 μm; ...

Embodiment 2

[0042] A millimeter-wave low-temperature co-fired ceramic material, comprising the following components, calculated by weight percentage:

[0043] Glass composition 49%; Aluminum oxide 51%;

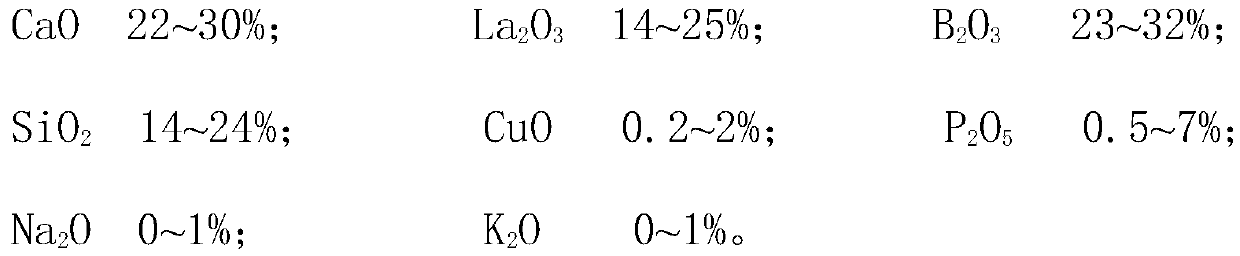

[0044] The glass composition includes the following components, calculated by weight percentage:

[0045]

[0046] A method for preparing a millimeter-wave low-temperature co-fired ceramic material: comprising the following steps:

[0047] S1: Preparation of glass composition

[0048] Weigh the raw materials of the above-mentioned glass composition according to parts by weight; mix and dry the raw materials with a ball mill; put them into a crucible, the temperature of the crucible is 1350°C, and continue to heat the crucible to 1450°C and melt for 60 minutes, then pour it into deionized water to cool Quenching to obtain glass slag, and performing airflow grinding on the glass slag to obtain glass powder, the particle size of the glass powder is D50, and the length is 5-7 μm;

[004...

Embodiment 3

[0052] A millimeter-wave low-temperature co-fired ceramic material, comprising the following components, calculated by weight percentage:

[0053] Glass composition 45%; Aluminum oxide 55%;

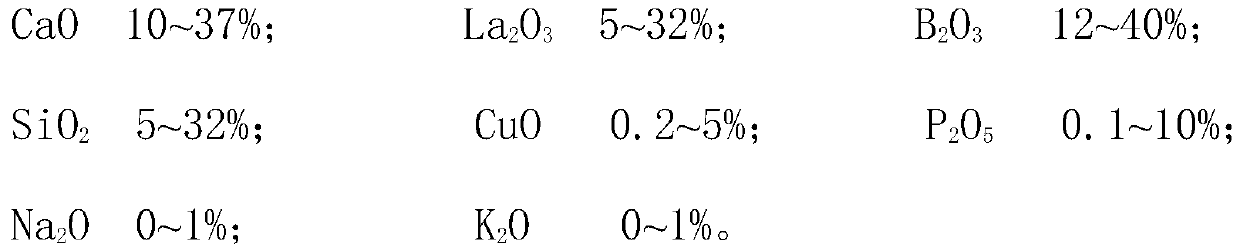

[0054] The glass composition includes the following components, calculated by weight percentage:

[0055]

[0056] A method for preparing a millimeter-wave low-temperature co-fired ceramic material: comprising the following steps:

[0057] S1: Preparation of glass composition

[0058] Weigh the raw materials of the above-mentioned glass composition according to parts by weight; mix and dry the raw materials with a ball mill; put them into a crucible, the temperature of the crucible is 1350°C, and continue to heat the crucible to 1450°C and melt for 60 minutes, then pour it into deionized water to cool Quenching to obtain glass slag, and performing airflow grinding on the glass slag to obtain glass powder, i.e. glass powder, the particle size of the glass-ceramic is D50, and the lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com